Low-impedance high-efficiency air filtering material and preparation method thereof

An air filter material and high-efficiency technology, applied in the direction of filtration separation, membrane filter, separation method, etc., can solve the problems of high resistance and high energy consumption of air filter materials, so as to ensure filtration efficiency, reduce energy consumption, and enhance bonding force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

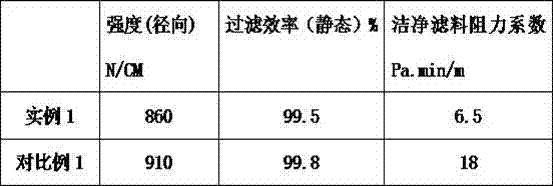

Examples

preparation example Construction

[0024] The preparation method of the air filter material of above-mentioned embodiment, comprises:

[0025] Step 10) Feed two kinds of fibers with different melting points into the cotton box, mix them evenly, and comb them into a web through a carding machine;

[0026] Wherein, in step 10), the two fibers with different melting points refer to PET short fibers and PP short fibers. Preferably, the thickness of the PET short fiber is 1.5D, the thickness of the PP short fiber is 1.35D, and the PET short fiber and the 1.35D PP short fiber are mixed according to a mass ratio of 1:1.

[0027] Step 20) Arrange the needle-punched nonwoven into the oven, use hot air to penetrate the needle-punched nonwoven, and make the needle-punched nonwoven in a semi-molten state; then transfer the needle-punched nonwoven to the Cold rollers are used for rapid cold shock setting to form a non-woven needle-punched filter felt as the base layer.

[0028] Wherein, in step 20), preferably, the needle...

example 1

[0046] A method for preparing a low-impedance high-efficiency air filter material, comprising:

[0047] Step 10) Feed two kinds of fibers with different melting points into the cotton box, mix them evenly, and comb them into a web through a carding machine; D PET staple fibers and PP staple fibers with a thickness of 1.35D, and PET staple fibers and 1.35D PP staple fibers are mixed according to the mass ratio of 1:1.

[0048] Step 20) Put the needle-punched nonwoven fabric into the oven at a speed of 3 meters per minute, use hot air to penetrate the needle-punched nonwoven fabric, and make the needle-punched nonwoven fabric in a semi-molten state; then under the action of the conveying curtain The needle-punched non-woven fabric is sent to the cold roll for rapid cooling and setting to form a non-woven needle-punched filter felt as the base layer; the temperature of the hot air is 8°C lower than the melting temperature of fibers with a lower melting point.

[0049] Step 30) W...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com