Screening-cleaning combined device for cereal for making wine

A combination of equipment and grain technology, applied in the direction of sieving, separating solids from solids with airflow, solid separation, etc., can solve the problems of vibration motor frequency and power increase, loss, natural environment and working environment pollution, etc., to achieve The effect of increasing the vibration amplitude and optimizing the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

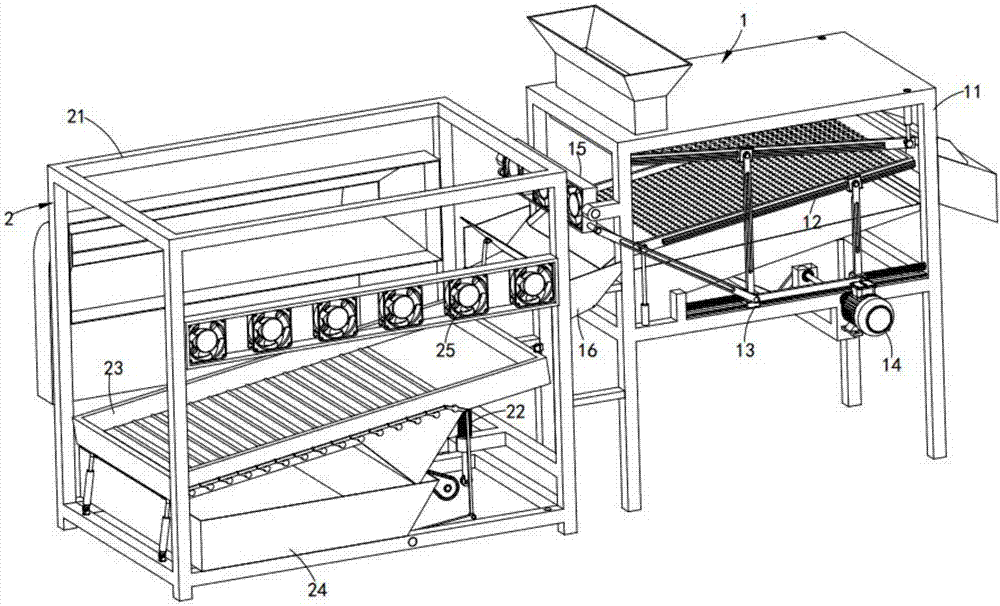

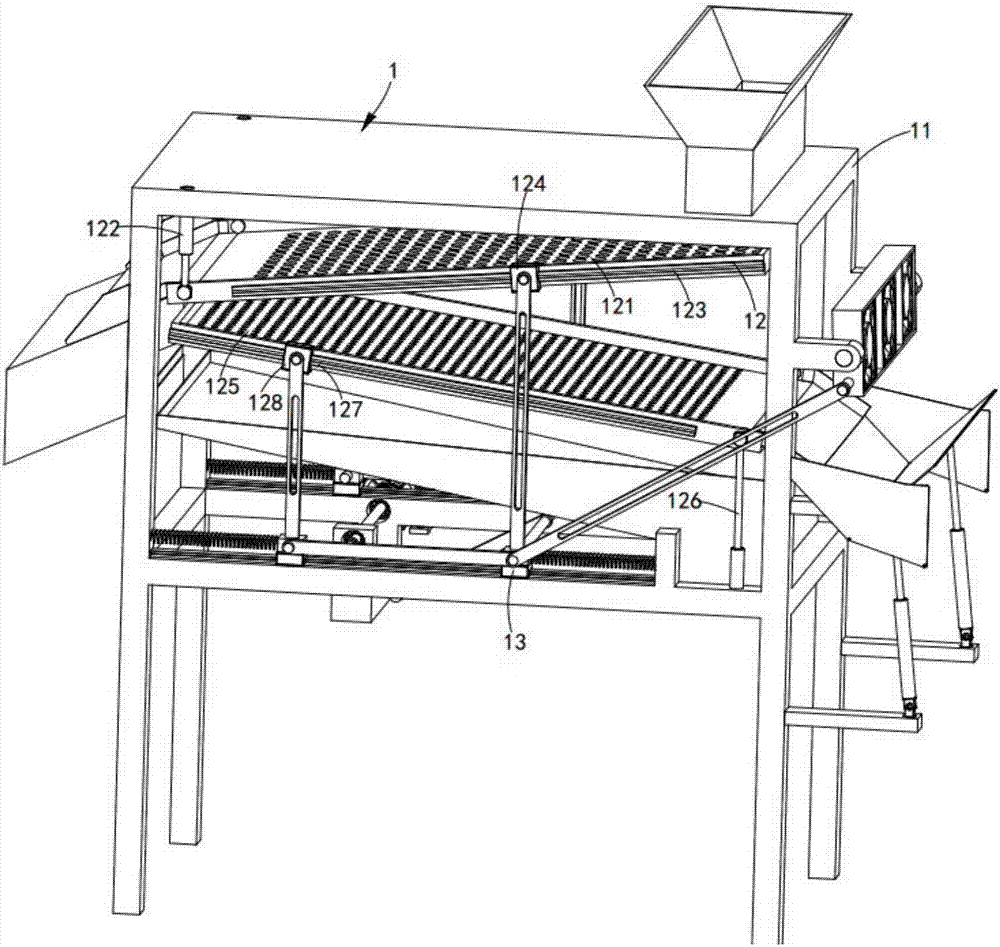

[0076] Such as figure 1 As shown, a combined equipment for screening and removing impurities for winemaking, including a resonant wind screener 1 and a vibrating grain huller 2, the resonant wind screener 1 is arranged on the front side of the vibrating grain huller 2, its For screening grain, it includes a first frame 11, a screening mechanism 12, a resonance mechanism 13, a first drive mechanism 14, a direction-changing air outlet mechanism 15, and an intermittent discharge mechanism 16, and the screening mechanism 12 is set In the middle of the first frame 11, a resonance mechanism 13 and a first drive mechanism 14 are arranged below it, and the first drive mechanism 14 drives the resonance mechanism 13 to operate, and a direction-changing air outlet mechanism 15 is also arranged behind the screening mechanism 12 And the intermittent discharge mechanism 16, the reversing air discharge mechanism 15 is arranged directly above the intermittent discharge mechanism 16;

[0077]...

Embodiment 2

[0127] Figure 14 It is a schematic structural view of Embodiment 2 of a combined equipment for screening and removing impurities from grains used in brewing according to the present invention; Figure 14 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. This embodiment two and figure 1 The difference of the shown embodiment one is:

[0128] Such as Figure 14 As shown, a combined equipment for screening and removing impurities for wine making, the collection mechanism 24 includes several swing leaves 241, double-headed connecting rods 242, several single-headed connecting rods 243, first swinging connecting rods 244, second swinging connecting rods Rod 245, rotating shaft 246, second roller 247, receiving hopper 248, and feed bin 249, the two ends of de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com