Method for preparing 2- acetylthiophene

A technology of acetylthiophene and thiophene, which is applied in the field of 2-acetylthiophene preparation, can solve the problems of high environmental protection pressure and large industrial sewage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

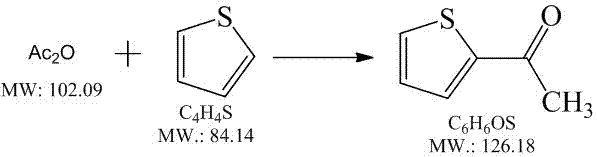

[0038] The present invention provides a kind of green 2-acetylthiophene preparation method on the one hand, described method comprises the following steps:

[0039] First add thiophene, acetic anhydride and catalyst into the reaction kettle, react at 70-80°C for 3-5 hours, and then directly rectify to obtain the product. The remaining bottoms of the reactor can be directly applied to the next batch of reactions, and the next batch of reactions does not need to add catalysts.

[0040] In a preferred example of the present invention, the preparation method of 2-acetylthiophene is obtained by reacting thiophene with acetic anhydride in a solvent-free or organic solvent. This reaction can be carried out without adding a solvent, and the reaction can be carried out with a halogenated hydrocarbon such as thiophene, acetic anhydride, acetic acid, methylene chloride, chloroform, 1,2-dichloroethane as a solvent, preferably without a solvent.

[0041] In a preferred example of the pres...

Embodiment 1

[0046] and see attached figure 1, Add thiophene (84kg, purity 99%, provided by Shanxi Hengqiang Chemical Co., Ltd.) and acetic anhydride (102kg,) into the reactor, then add 500g of phosphoric acid, heat to 70-80°C, and react for 2-3 hours. After GC detection, the reaction is completed, rectified, and the product is collected according to the boiling point of the fraction. A total of 118kg (94% yield) of 2-acetylthiophene was obtained.

[0047] After the distillation is completed, add thiophene (84kg, purity 99%, provided by Shanxi Hengqiang Chemical Co., Ltd.) and acetic anhydride (102kg) into the reactor, heat to 70-80°C, and react for 2-3 hours. After GC detection, the reaction is completed, rectified, and the product is collected according to the boiling point of the fraction. A total of 120kg (95% yield) of 2-acetylthiophene was obtained. GC: 99.95%.

Embodiment 2

[0049] Add thiophene (84kg, purity 99%, provided by Shanxi Hengqiang Chemical Co., Ltd.), acetic anhydride (102kg,) and acetic acid (100kg) into the reactor, then add 500g of phosphoric acid, heat to 70-80°C, and react for 2-3 hours . After GC detection, the reaction is completed, rectified, and the product is collected according to the boiling point of the fraction. A total of 119kg (95% yield) of 2-acetylthiophene was obtained.

[0050] After the distillation is completed, add thiophene (84kg, purity 99%, provided by Shanxi Hengqiang Chemical Co., Ltd.), acetic anhydride (102kg), and acetic acid (100kg) into the reactor, heat to 70-80°C, and react 2 -3 hours. After GC detection, the reaction is completed, rectified, and the product is collected according to the boiling point of the fraction. A total of 120kg (95% yield) of 2-acetylthiophene was obtained. GC: 99.95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com