Continuous synthesis method of metalorganic frame compound with stepped hole structure

A technology of metal-organic frameworks and synthesis methods, which is applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physical-chemical processes, etc., and can solve the problems of long cycle times, continuous production of step-pore MOFs, and limited applications, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

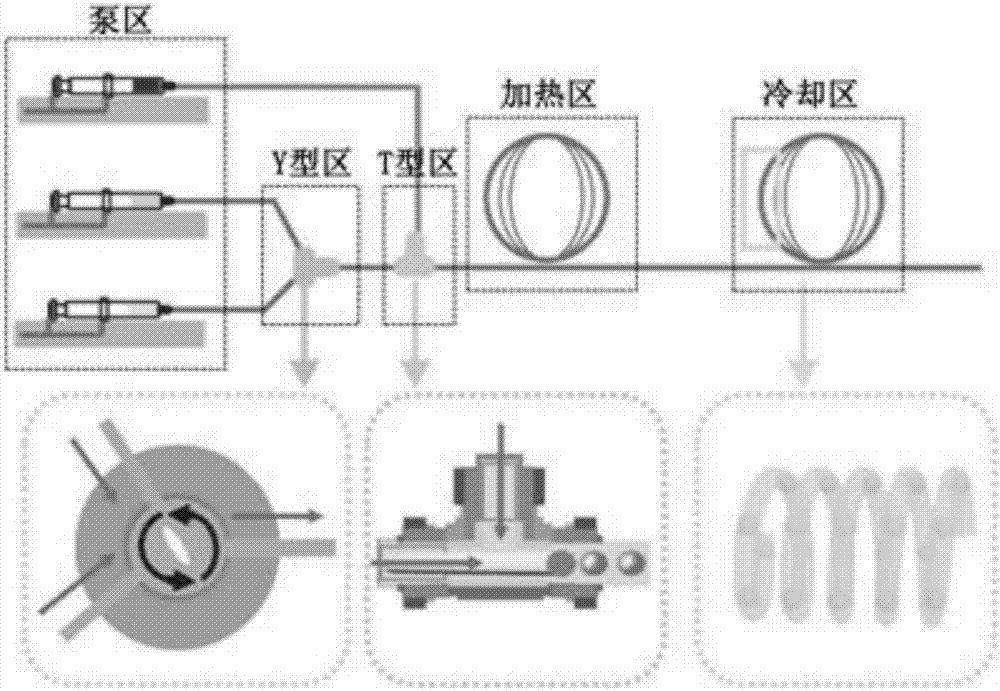

[0052] 1) According to the attached figure 1 Build a continuous reaction device. The device includes: three pumps connected to three branches, No. 1 pump injects metal salt solution, No. 2 pump injects organic ligand, No. 3 pump injects continuous phase; No. 1 pump and No. 2 pump are connected to Y-type micro-reaction pipeline, Y-type The center of the micro-reaction pipeline is a mixer, and the mixer is connected with the No. 3 pump to a T-shaped multi-layer structure micro-reaction pipeline. The pipeline at the outlet of the T-shaped pipeline is connected to the pipelines in the heating zone and the cooling zone in turn, and the product collection is set at the outlet of the cooling zone. device. Use a high-pressure syringe pump, select a polytetrafluoroethylene tube or a stainless steel tube with an inner diameter of 2mm, and place it in the heating zone with a length of 2m.

[0053] 2) Disperse copper nitrate in a 1:1 mixed solution of ethanol and N,N-dimethylformamide, ...

Embodiment 2

[0060] A method for continuously synthesizing a metal-organic framework compound with a hierarchical pore structure, comprising the following steps:

[0061] 1) According to the attached figure 1 Build a continuous reaction device. The device includes: three pumps connected to three branches, No. 1 pump injects metal salt solution, No. 2 pump injects organic ligand, No. 3 pump injects continuous phase; No. 1 pump and No. 2 pump are connected to Y-type micro-reaction pipeline, Y-type The center of the micro-reaction pipeline is a mixer, and the mixer is connected with the No. 3 pump to a T-shaped multi-layer structure micro-reaction pipeline. The pipeline at the outlet of the T-shaped pipeline is connected to the pipelines in the heating zone and the cooling zone in turn, and the product collection is set at the outlet of the cooling zone. device. Use a high-pressure injection pump, select a polytetrafluoroethylene tube or a stainless steel tube with an inner diameter of 2mm,...

Embodiment 3

[0069] A method for continuously synthesizing a metal-organic framework compound with a hierarchical pore structure, comprising the following steps:

[0070] 1) According to the attached figure 1 Build a continuous reaction device. The device includes: three pumps connected to three branches, No. 1 pump injects metal salt solution, No. 2 pump injects organic ligand, No. 3 pump injects continuous phase; No. 1 pump and No. 2 pump are connected to Y-type micro-reaction pipeline, Y-type The center of the micro-reaction pipeline is a mixer, and the mixer is connected with the No. 3 pump to a T-shaped multi-layer structure micro-reaction pipeline. The pipeline at the outlet of the T-shaped pipeline is connected to the pipelines in the heating zone and the cooling zone in turn, and the product collection is set at the outlet of the cooling zone. device. Use a high-pressure syringe pump, select a polytetrafluoroethylene tube or a stainless steel tube with an inner diameter of 2mm, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mesopore | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com