Continuous calcium carbonate production system and method

A production method and production system technology, applied in calcium carbonate/strontium/barium, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of high energy consumption, serious dust pollution, low product whiteness and fineness, etc. , to achieve the effect of low heavy metal content, high product purity and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

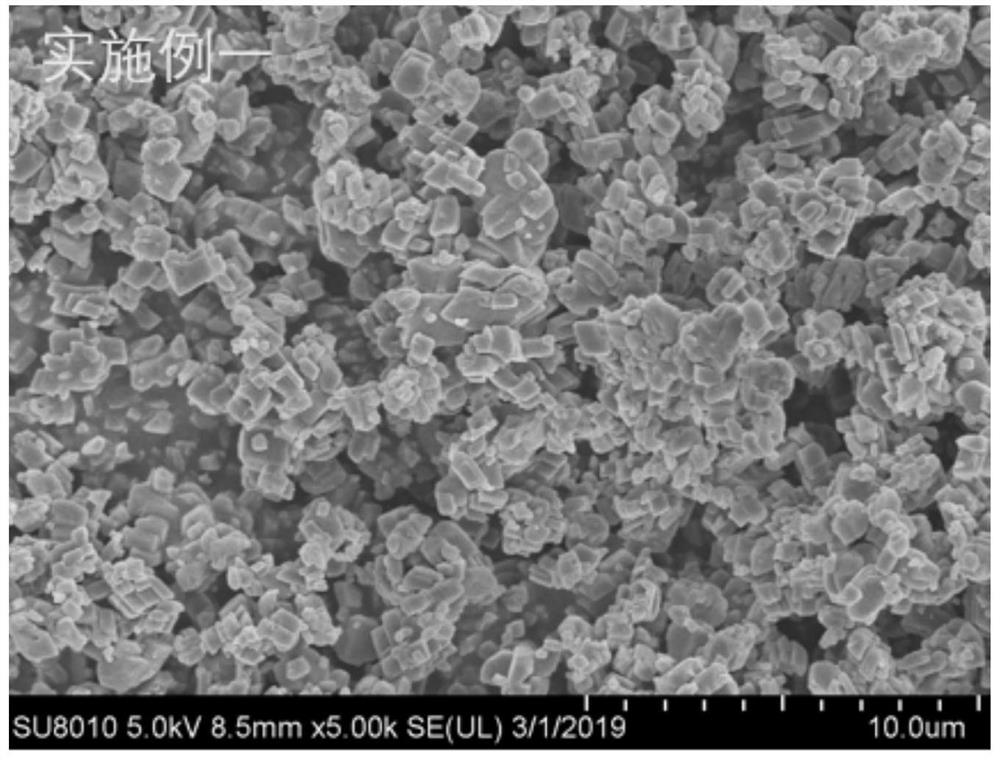

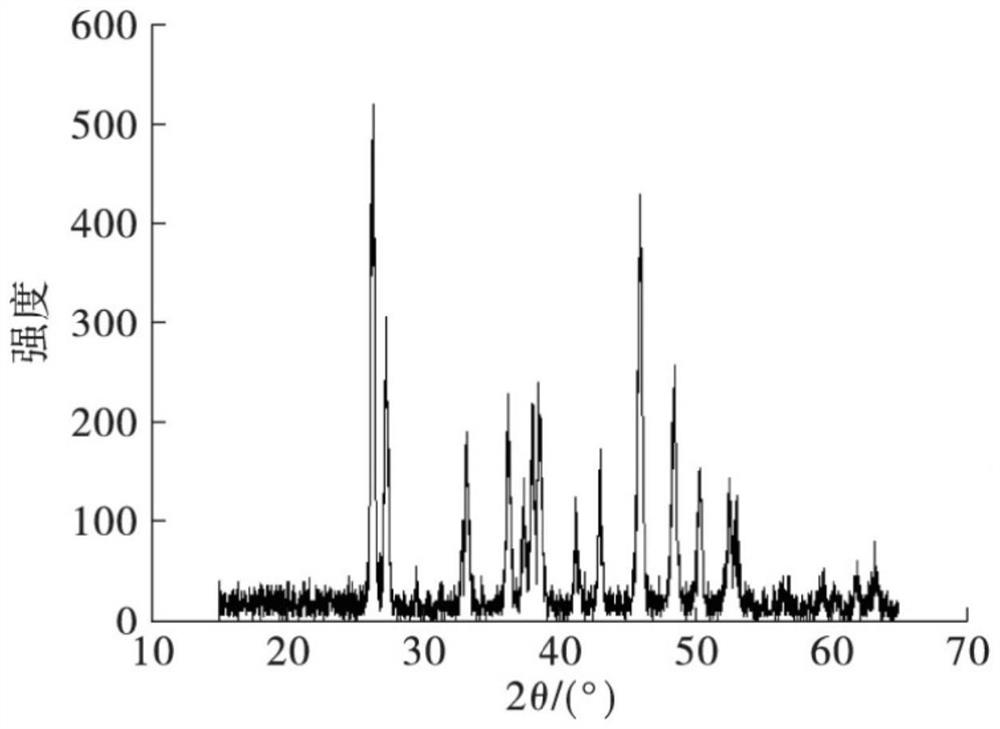

Embodiment 1

[0048] Na 2 CO 3 Be made into the solution that mass fraction is 35%, feed with the feed rate feed of 7.9g / min by feed pump; CaCl 2 Be made into the solution that mass fraction is 14%, feed with the feed rate feed of 20g / min by feed pump, sodium carbonate solution feeds from the upper end of continuous flow reactor, and calcium chloride solution enters from the lower end of continuous flow reactor Material, Ca 2+ with CO 3 2- The molar ratio is 1:1.05, the pH value of the reaction system is 9.0, and the reaction temperature is 80°C. After 10 seconds of reaction, the slurry is transferred from the pipeline to the aging reactor for aging. The aging temperature is 80°C, and the aging time is 0.5h. Then start to discharge continuously. After suction filtration, washing and drying, high-purity calcium carbonate products are obtained, such as Figure 1~2 shown. Calcium carbonate as Ca 2+ The meter contains a purity of 99.8% as CO 3 2-The calculated purity is 99.9%.

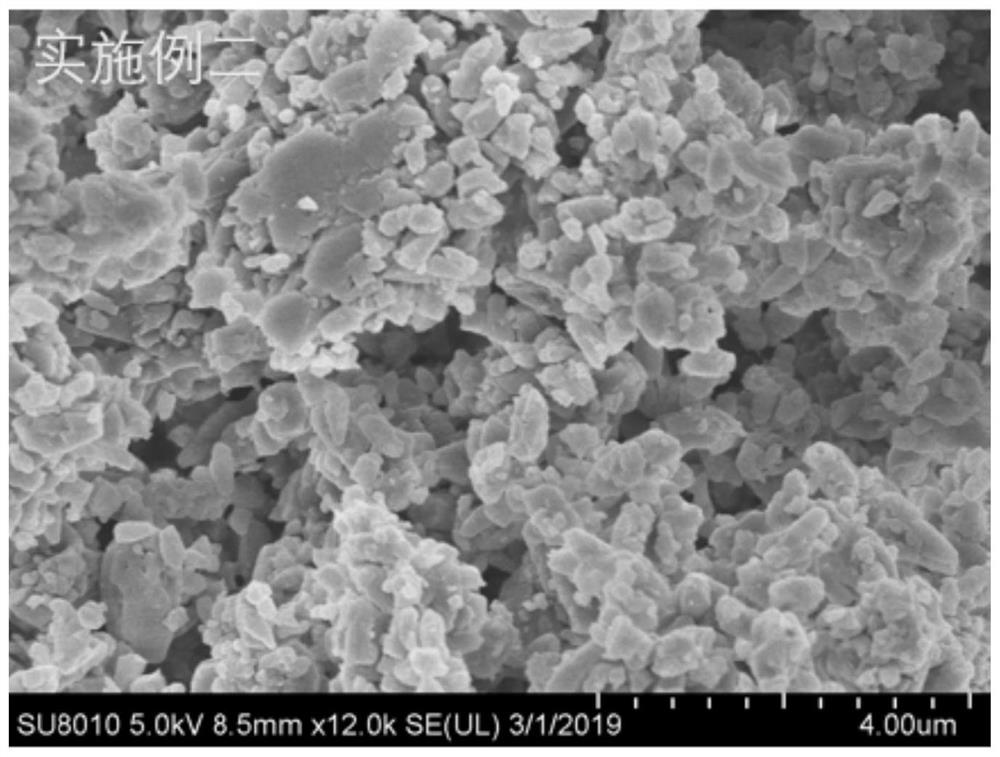

Embodiment 2

[0050] First put (NH 4 ) 2 CO 3 Be made into the solution of mass fraction 32%, feed with the feed rate feed of 7.8g / min by feed pump; CaCl 2 Be made into the solution of mass fraction 14%, feed with the feed rate feed of 20g / min by feed pump, ammonium carbonate solution feeds from the upper end of continuous flow reactor, and calcium chloride solution feeds from the lower end of continuous flow reactor , Ca 2+ with CO 3 2- The molar ratio is 1:1.05, the pH value of the reaction system is 7.0, and the reaction temperature is 70°C. After 15 seconds of reaction, the slurry is transferred from the pipeline to the aging reactor for aging. The aging temperature is 70°C, and the aging time is 0.6h. Then start to discharge continuously. After suction filtration, washing and drying, high-purity calcium carbonate products are obtained, such as Figure 3-4 shown. Calcium carbonate as Ca 2+ The meter contains a purity of 98.8%, based on CO 3 2- The calculated purity was 99.0%....

Embodiment 3

[0052] Na 2 CO 3 Be made into the solution of mass fraction 32%, feed with the feed rate feed of 8.3g / min by feed pump; Ca(NO 3 ) 2 Be made into the solution of mass fraction 21%, feed with the feed rate feed of 20g / min by feed pump, sodium carbonate solution feeds from the lower end of continuous flow reactor, calcium nitrate solution feeds from the upper end of continuous flow reactor, Ca 2+ with CO 3 2- The molar ratio is 1:1.1, the pH value of the reaction system is 10.0, and the reaction temperature is 60°C. After 20s of reaction, the slurry is transferred from the pipeline to the aging reactor for aging. The aging temperature is 60°C, and the aging time is 0.7h. Then start to discharge continuously. After suction filtration, washing and drying, high-purity calcium carbonate products are obtained, such as Figure 5-6 shown. Calcium carbonate as Ca 2+ The meter contains a purity of 99.1%, as CO 3 2- The calculated purity is 99.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com