Preparation method of monodisperse nano ITO

A monodisperse and nanotechnology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve problems that hinder the industrialization process of material preparation, difficult to control reaction conditions, special equipment requirements, etc., to improve sintering and agglomeration problems, The effect of stable product performance and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

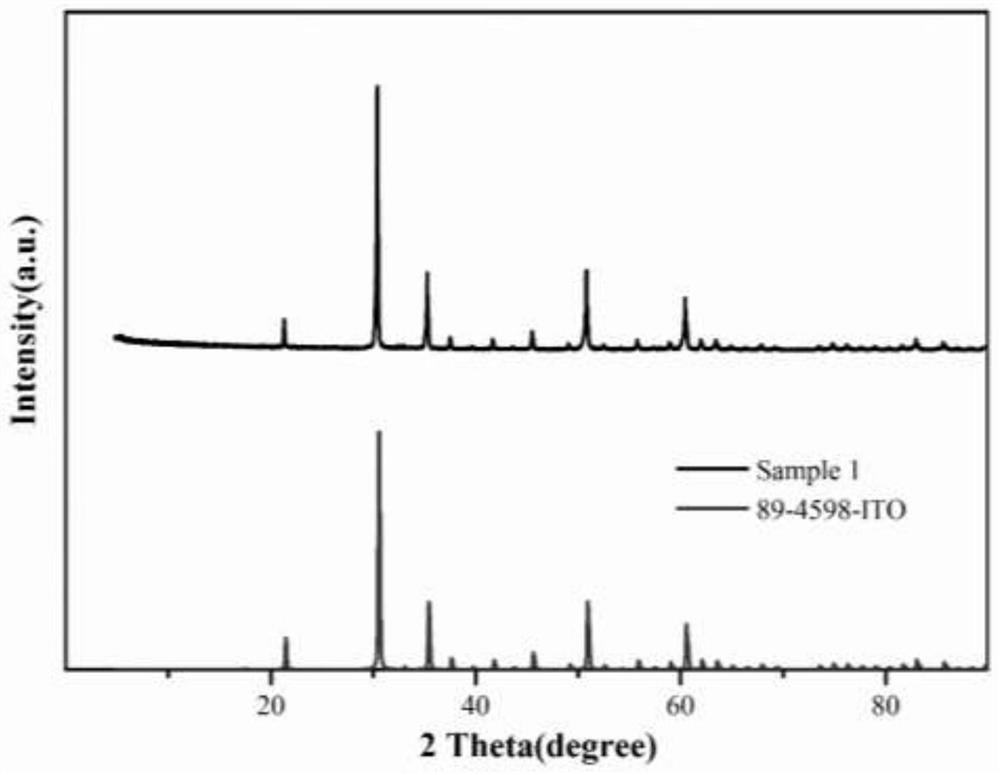

Embodiment 1

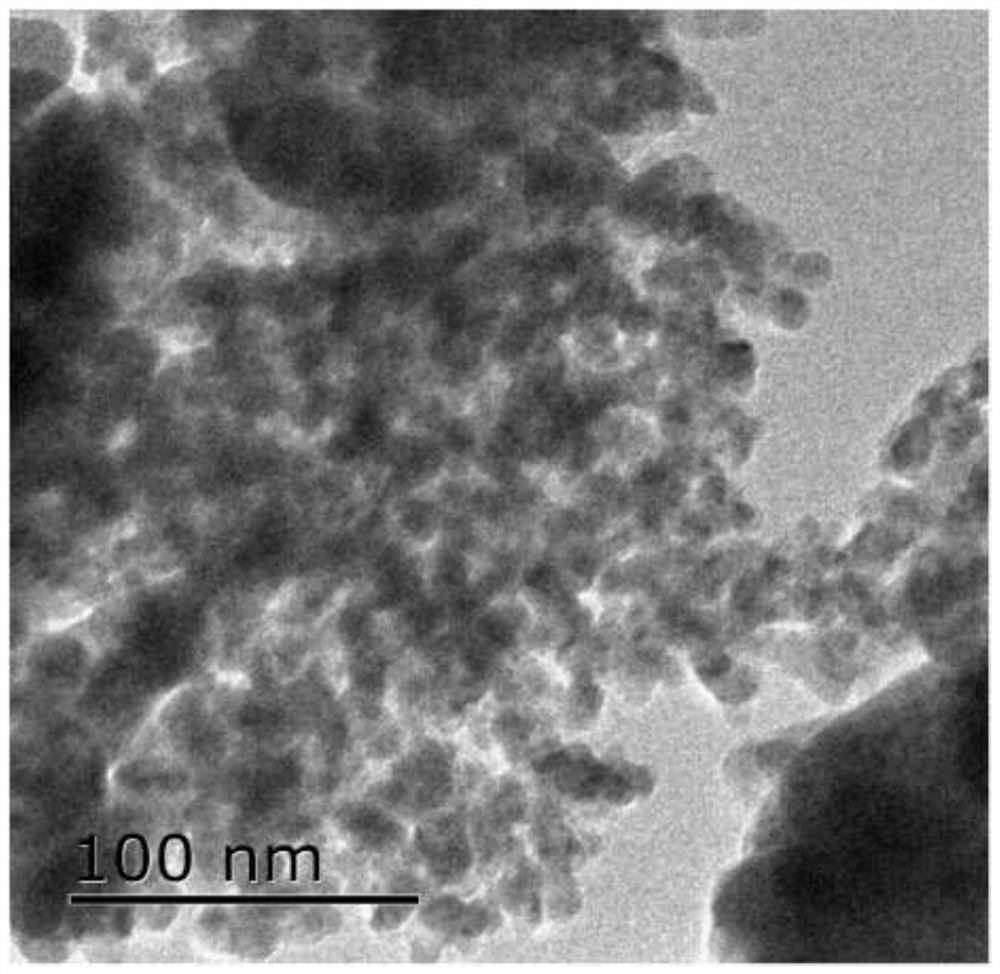

[0040] A preparation method of monodisperse nanometer ITO, comprises the steps:

[0041] 1) Prepare 10 ml of hydrochloric acid aqueous solution with a pH value of 1 and pour it into a round-bottomed flask; then weigh 0.5 g of sodium chloride crystals, add the obtained acidic aqueous solution and fully dissolve, and mix uniformly to obtain a mixed solution I;

[0042] 2) Weigh 0.1504g of indium nitrate hydrate and 0.0179g of tin tetrachloride crystals and dissolve them in the obtained mixed solution I, then add 1.0g of cetyltrimethylammonium bromide and 100ml of benzene, mix well to form microemulsion II ;

[0043] 3) The obtained microemulsion II was subjected to azeotropic distillation at 90°C for 4 hours, and then dried to obtain a solid powder; then the dried solid powder was calcined at 600°C for 2 hours, and deionized water was passed through a centrifuge for 8000r / min wash and centrifuge to remove the salt from the sample, and finally dry the precipitate to obtain the ...

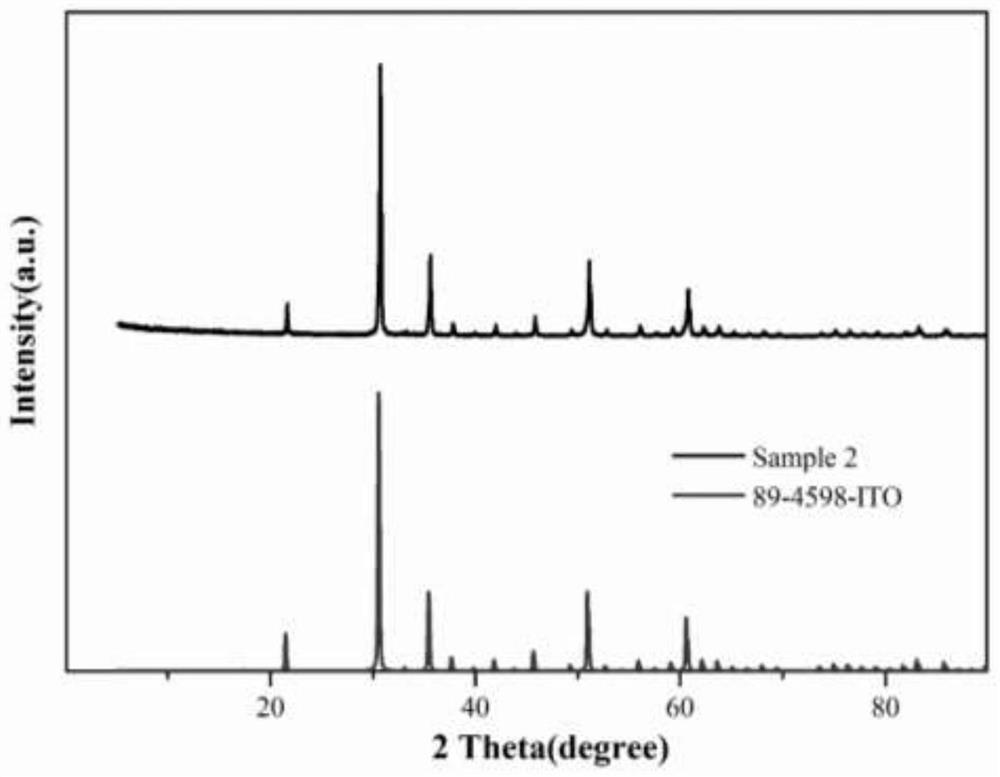

Embodiment 2

[0047] A preparation method of monodisperse nanometer ITO, comprises the steps:

[0048] 1) Prepare 20ml of nitric acid aqueous solution with a pH value of 3 and pour it into a round-bottomed flask; then weigh 0.8g of sodium sulfate crystals and add the resulting acidic aqueous solution to fully dissolve, mix well to obtain mixed solution I;

[0049] 2) Weigh 0.1504g of indium nitrate hydrate and 0.0524g of stannous chloride and dissolve it in the obtained mixed solution I, then add 0.5g of cetyltrimethylammonium bromide and 70ml of benzene, and mix uniformly to form microemulsion II;

[0050] 3) The obtained microemulsion II was subjected to azeotropic distillation at 75°C for 6h, and then dried to obtain a solid powder; then the dried solid powder was calcined at 800°C for 3h, and deionized water was passed through a centrifuge for 8000r / min wash and centrifuge to remove the salt from the sample, and finally dry the precipitate to obtain the final product.

[0051] The pro...

Embodiment 3

[0054] A preparation method of monodisperse nanometer ITO, comprises the steps:

[0055] 1) Prepare 10 ml of sulfuric acid aqueous solution with a pH value of 0.96 and pour it into a round-bottomed flask; then weigh 2.0 g of sodium chloride crystals and add the obtained acidic aqueous solution to fully dissolve, and mix well to obtain a mixed solution I;

[0056] 2) Weigh 0.2806g of indium sulfate hydrate and 0.1179g of stannous oxalate crystals and dissolve them in the obtained mixed solution I, then add 3.0g of cetyltrimethylammonium bromide and 100ml of benzene, and mix uniformly to form microemulsion II;

[0057] 3) The obtained microemulsion II was subjected to azeotropic distillation at 100°C for 6 hours, and then dried to obtain a solid powder; then, the dried solid powder was calcined at 700°C for 3 hours, and deionized water was passed through a centrifuge for 8000r / min wash and centrifuge to remove the salt from the sample, and finally dry the precipitate to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com