A kind of polyvinyl acetal resin composition and resin-coated copper foil

A polyvinyl acetal resin, polyvinyl alcohol technology, applied in coatings, fire-resistant coatings, etc., can solve the problem of unsatisfactory peeling resistance and high temperature resistance, unstable adhesion between glue and copper foil, affecting resin-coated copper Foil quality and other issues, to achieve ideal peel strength, good washing effect, and excellent high temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

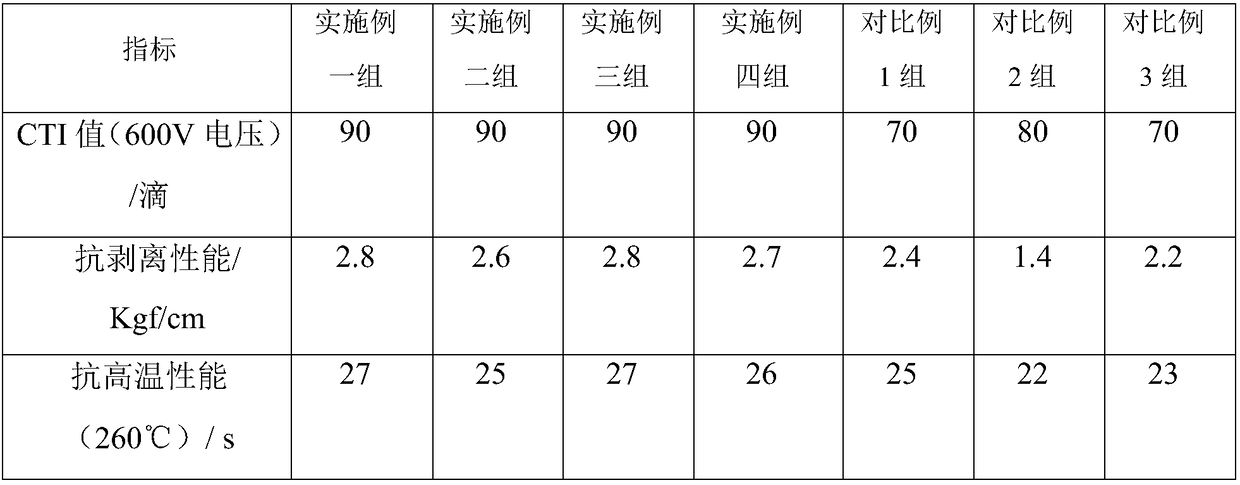

[0032] Embodiment 1 polyvinyl acetal resin composition

[0033] The polyvinyl acetal resin composition comprises, in parts by mass, 80 parts of polyvinyl butyral, 2 parts of acetic acid and 18 parts of polyvinyl alcohol, and the degree of polymerization of the polyvinyl alcohol is 2100.

Embodiment 2

[0034] Embodiment two polyvinyl acetal resin composition

[0035] The polyvinyl acetal resin composition, in parts by mass, includes 79 parts of polyvinyl butyral, 2.5 parts of acetic acid and 18.5 parts of polyvinyl alcohol, and the degree of polymerization of the polyvinyl alcohol is 2150.

Embodiment 3

[0038] The preparation method of embodiment three polyvinyl acetal resin composition

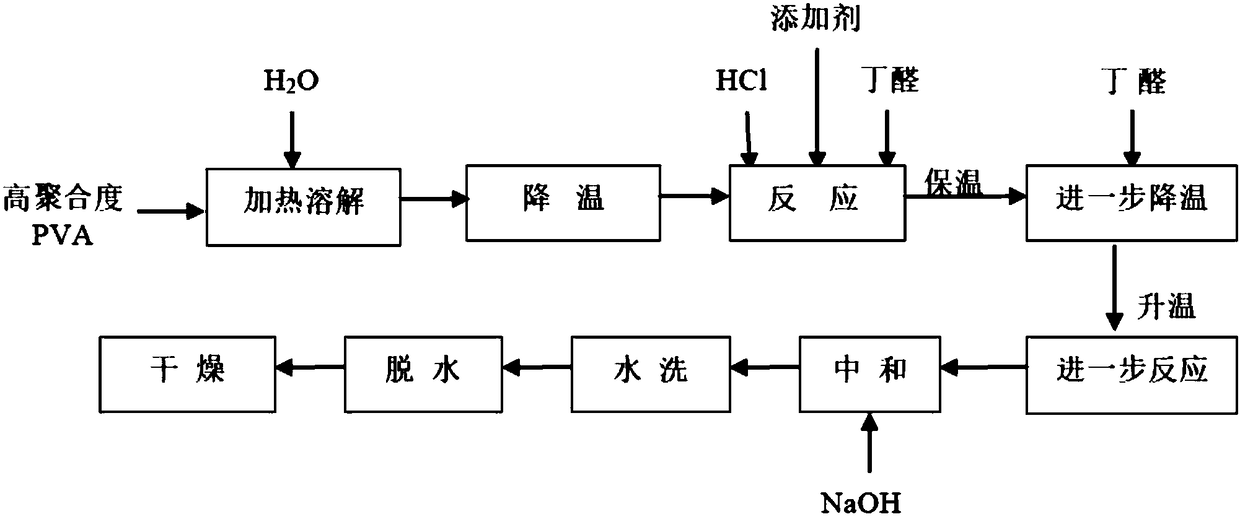

[0039] The preparation method of polyvinyl acetal resin composition comprises the steps:

[0040] S1 Dissolve 34Kg of polyvinyl alcohol in water at a high temperature of 92°C to obtain an aqueous polyvinyl alcohol solution with a mass percentage of 9%, filter it, and place it in a reaction kettle;

[0041] S2 Cool down the reactor to 40°C, add an acid catalyst, acetaldehyde with 0.5% by weight of the polyvinyl alcohol and butyraldehyde with 18.5% by weight of the polyvinyl alcohol for acetalization reaction for 2 hours, then lower the temperature to 10°C , adding 30% butyraldehyde by weight of the polyvinyl alcohol, then slowly raising the temperature to 65° C. and keeping it warm for 3 hours to obtain a reaction product;

[0042] S3 Add sodium hydroxide solution to the reaction product to adjust the pH to 5.4, wash with water, separate by dehydration, and dry to obtain a polyvinyl acetal res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com