Epoxy prepreg composite material and preparation method thereof

A technology of composite materials and prepregs, which is applied in the field of preparation of epoxy prepreg composite materials, can solve the problems not related to the aging resistance of resin matrix composite materials, and achieve low yellowing index, good tensile strength, good Effect of aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

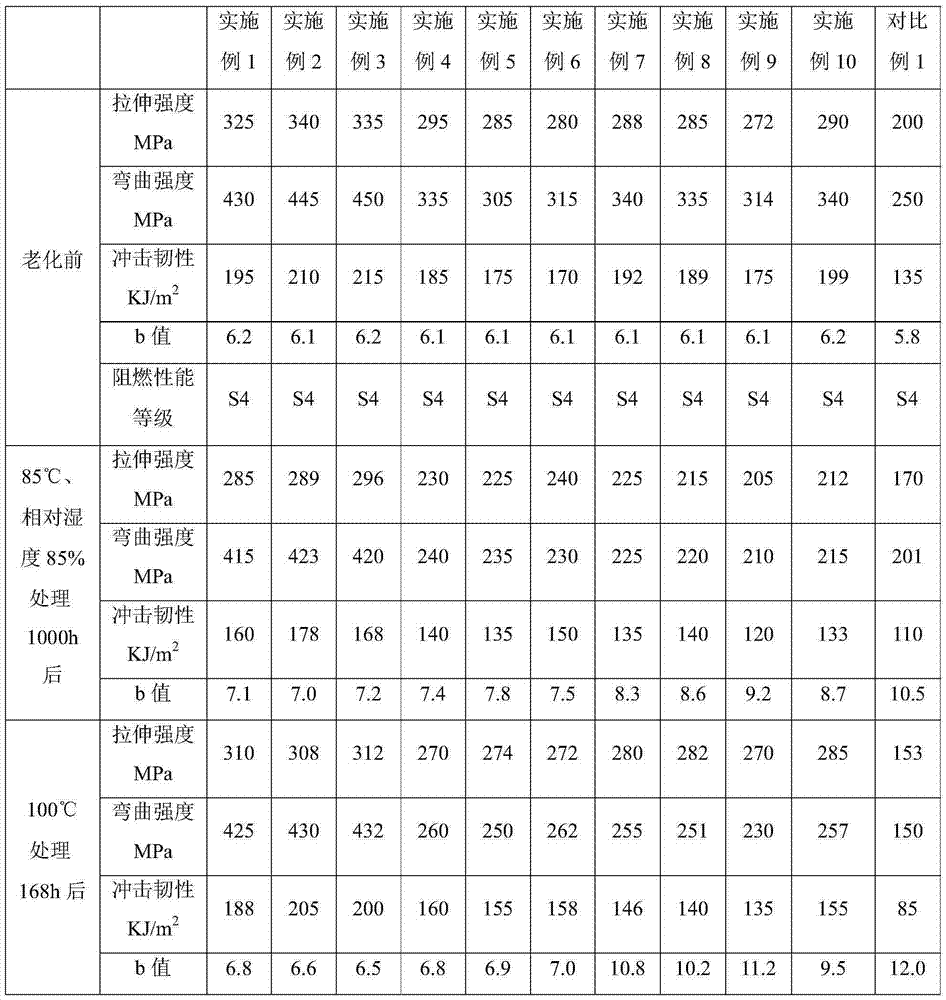

Examples

preparation example Construction

[0045] Second aspect, the present invention provides a kind of preparation method of epoxy prepreg composite material, and this method comprises:

[0046] (1) stirring evenly at least part of the liquid phase resin in the epoxy resin system with a curing agent and an accelerator, and then grinding to obtain an abrasive;

[0047] (2) Stir the solid phase resin in the epoxy resin system, the remaining liquid phase resin and the toughening agent evenly at 60-80°C, add a flame retardant, stir at 1000-1500rpm for 50-70min, and then The temperature is lowered to 60-65°C, the grinding material of step (1) is added, and stirred at 200-500rpm for 20-40min,

[0048] Wherein, the epoxy resin system contains hydrogenated bisphenol A type epoxy resin and / or hydrogenated bisphenol F type epoxy resin, also contains polyfunctional epoxy resin, bisphenol S type epoxy resin and novolac epoxy resin at least one of .

[0049] In the step (1) of the present invention, at least part of the liquid...

Embodiment 1

[0066] This example is used to illustrate the epoxy prepreg composite material of the present invention and its preparation method.

[0067] (1) the hydrogenated bisphenol A type epoxy resin of 45 parts by weight (purchased from Adidas, model 4080E, epoxy equivalent is 235g / eq, viscosity is 2500cP), dicyandiamide (particle diameter is 2500cP) of 8 parts by weight 3 μm), 4 parts by weight of 2,4-tolylenedimethylurea were stirred at 200 rpm for 30 minutes, and then ground twice with a three-roll mill (purchased from Qinhuangdao Beihang Machinery Co., Ltd., model S65, the same below);

[0068] (2) Adjust the temperature of the reactor to 75°C, add 25 parts by weight of multifunctional epoxy resin (purchased from Mitsubishi Chemical, model ERDM434L, epoxy equivalent is 115g / eq), o-cresol epoxy resin (purchased In South Asia, model 704) 30 parts by weight, polyester polyol (purchased from Huntsman, model DY965) 10 parts by weight, stirred at 1000rpm for 60min, then added saturated ...

Embodiment 2

[0070] This example is used to illustrate the epoxy prepreg composite material of the present invention and its preparation method.

[0071] (1) 30 parts by weight of hydrogenated bisphenol A type epoxy resin (purchased from Mitsubishi Chemical, model YX8034, epoxy equivalent is 290g / eq, viscosity is 90000cP), 10 parts by weight of diaminodiphenyl sulfone (particle diameter 5 μm), 3 parts by weight of 4,4'-methylenebis(phenyldimethylurea) were stirred at 350 rpm for 40 min, and then ground three times with a three-roll mill;

[0072] (2) Adjust the temperature of the reactor to 60°C, add 40 parts by weight of multifunctional epoxy resin (purchased from Mitsubishi Chemical, model 301E, epoxy equivalent is 101g / eq), o-cresol epoxy resin (purchased In South Asia, model 702) 30 parts by weight, polyhydroxyphenoxy resin (purchased from Mitsubishi Chemical, model 1256) 5 parts by weight, stirred at 1300rpm for 50min, then added saturated polyester resin (purchased from Langen, model...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com