A strengthening and toughening treatment process of high-nickel and low-carbon series steel

A treatment process and strengthening and toughening technology, which is applied in the field of strengthening and toughening treatment of high-nickel and low-carbon series steel, can solve the problem that the toughness of steel materials decreases, affects the safety of ultra-low temperature pressure vessels, and is difficult to significantly improve the high-nickel and low-carbon series steel. Low temperature toughness and other issues, to achieve the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

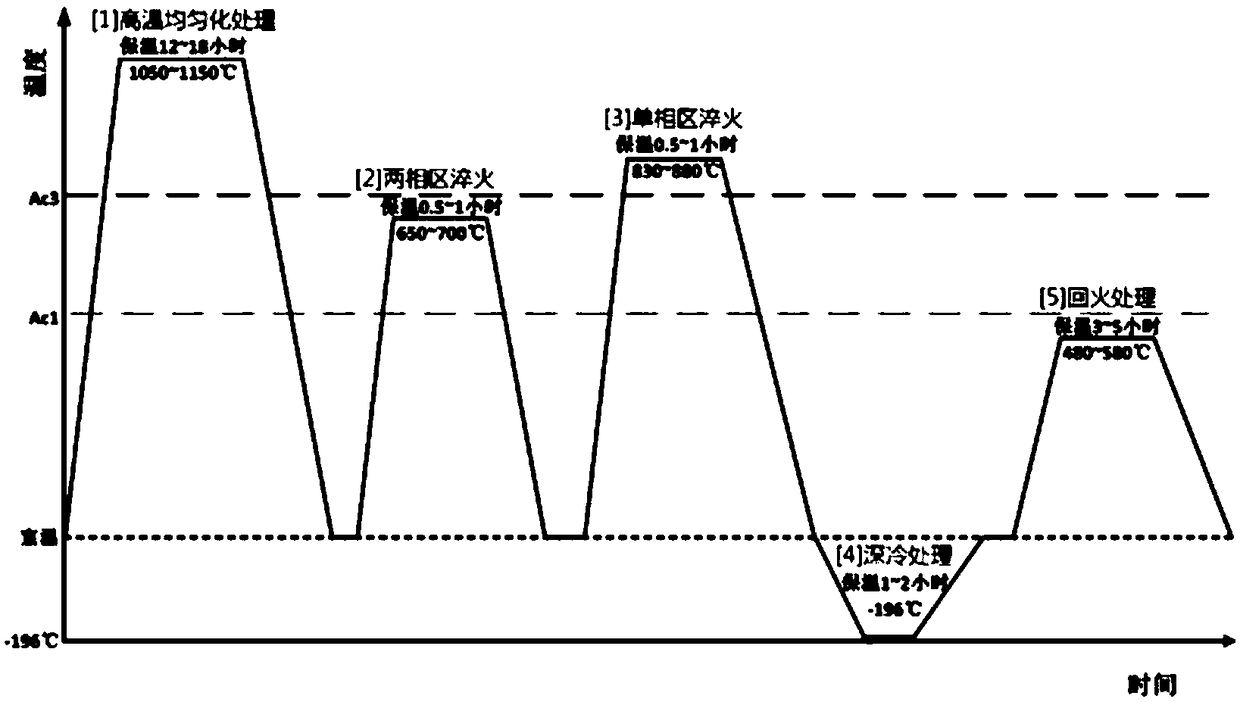

[0019] A process for strengthening and toughening high-nickel low-carbon series steels, the steps of which are:

[0020] Step 1: The material is 6.5Ni high-nickel low-carbon pressure vessel steel heated to 1150°C for 12 hours, then cooled to room temperature to obtain a martensite-based structure;

[0021] Step 2: Quenching in the two-phase region: reheat the martensite-based structure obtained in step 1 to the two-phase region at 670°C, keep it warm for 0.5 hours, and then immediately oil-quench to room temperature to obtain "new martensite + original Martensite" composite structure;

[0022] Step 3: Quenching in the single-phase zone: re-add the composite structure of "new martensite + original martensite" obtained in step 2 to 840°C for single-phase zone quenching, keep it warm for 0.5 hours, and then oil quench to room temperature to obtain the workpiece;

[0023] Step 4: Cryogenic treatment: Cool the workpiece obtained in step 3 to -196°C with liquid nitrogen, keep it wa...

Embodiment 2

[0027] A process for strengthening and toughening high-nickel low-carbon series steels, the steps of which are:

[0028] Step 1: Heating 9.5Ni high-nickel low-carbon pressure vessel steel to 1100°C for 16 hours, then cooling to room temperature to obtain a martensite-based structure;

[0029] Step 2: Quenching in the two-phase region: reheat the martensite-based structure obtained in step 1 to the two-phase region at 700°C, keep it warm for 1 hour, and then immediately oil-quench to room temperature to obtain "new martensite + original Martensite" composite structure;

[0030] Step 3: Quenching in the single-phase zone: re-add the composite structure of "new martensite + original martensite" obtained in step 2 to 850°C for single-phase zone quenching, keep it warm for 0.5 hours, and then oil quench to room temperature to obtain the workpiece;

[0031] Step 4: Cryogenic treatment: Cool the workpiece obtained in Step 3 to -196°C with liquid nitrogen, keep it warm for 1 hour, an...

Embodiment 3

[0035] A process for strengthening and toughening high-nickel low-carbon series steels, the steps of which are:

[0036] Step 1: Heating 9.5Ni high-nickel low-carbon pressure vessel steel to 1050°C for 18 hours, then cooling to room temperature to obtain a martensite-based structure;

[0037] Step 2: Quenching in the two-phase region: reheat the martensite-based structure obtained in step 1 to the two-phase region at 690°C, keep it warm for 40 minutes, and then immediately oil-quench to room temperature to obtain "new martensite + original Martensite" composite structure;

[0038] Step 3: Quenching in the single-phase zone: re-add the composite structure of "new martensite + original martensite" obtained in step 2 to 880°C for single-phase zone quenching, keep it warm for 1 hour, and then oil quench to room temperature to obtain the workpiece;

[0039] Step 4: Cryogenic treatment: Cool the workpiece obtained in step 3 to -196°C with liquid nitrogen, keep it warm for 1.5 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com