Method for detecting contents of SiO2 and Si in silicon-carbon composite material for lithium ion battery

A technology of silicon-carbon composite materials and lithium-ion batteries, which is applied in the direction of analyzing materials, analyzing materials through optical means, and analyzing materials through chemical reactions. It can solve the problems of harsh detection conditions and complicated processes, and achieve simple operation. , high sensitivity and wide linear range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

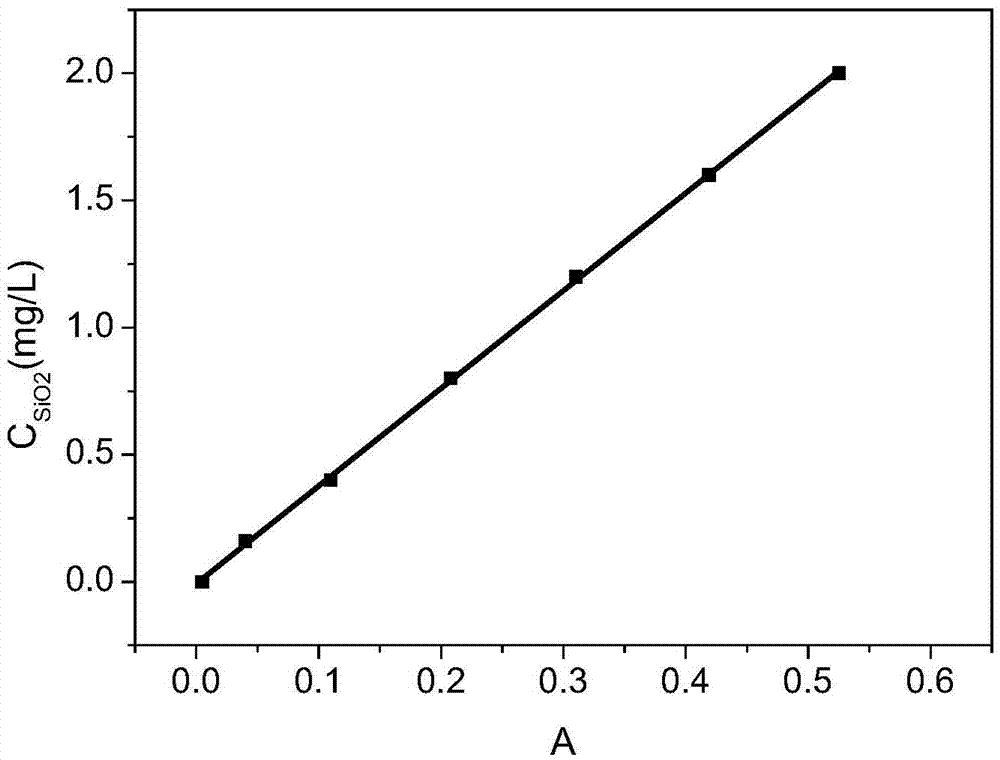

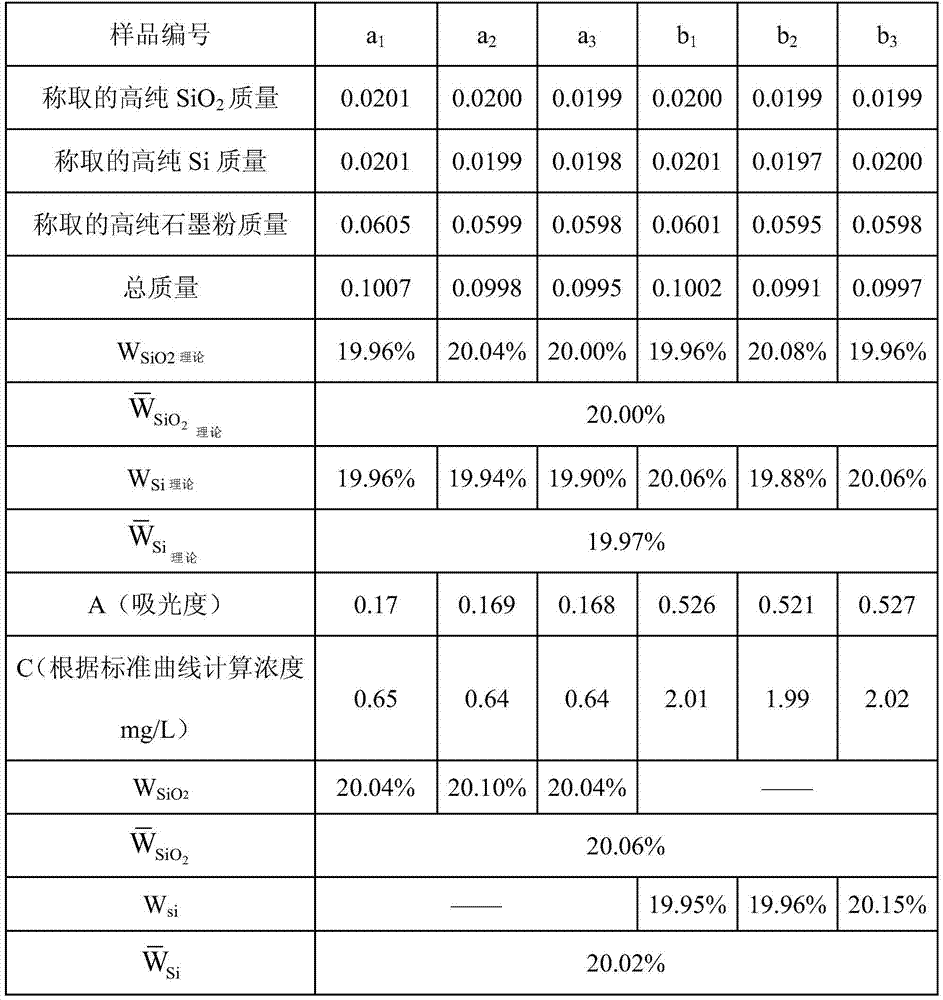

[0054] SiO in standard 2 , Si content detection

[0055] The standard product uses high-purity SiO 2 , high-purity silicon powder, and high-purity graphite powder for preparation. If a mixed standard substance is prepared, test abnormalities may occur due to uneven mixing of the three substances. Therefore, in the test of this embodiment, each sample is independently and accurately weighed three substances, and the mass error is controlled within ±0.0010g.

[0056] (1) SiO in the standard product 2 Content detection

[0057] Accurately weigh high-purity SiO 2 Reagent 0.0200±0.0010g, high-purity silicon powder 0.0200±0.0010g, high-purity graphite powder 0.0600±0.0010g, put in a polytetrafluoroethylene plastic container, add 5mL 10wt% hydrochloric acid solution, 5mL 15wt% hydrofluoric acid solution, quickly tighten the plastic container, place it in a 50°C water bath and heat it for 10 minutes, take it out, cool it with running water, shake it well, and dilute it in a 250...

Embodiment 2

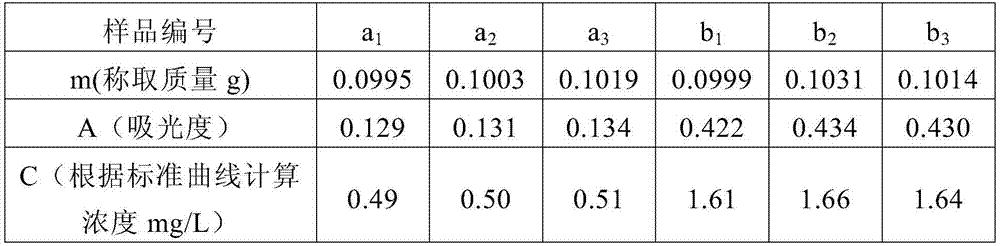

[0066] SiO in actual samples 2 , Si content detection

[0067] (1) SiO in the sample 2 Content detection

[0068] Accurately weigh 0.1000±0.0020g of the vacuum-dried sample, place it in a polytetrafluoroethylene plastic container, add 5mL of 10wt% hydrochloric acid solution and 5mL of 15wt% hydrofluoric acid solution in sequence, quickly tighten the plastic container, and place Heat it in a water bath at 50°C for 10 minutes, take it out and cool it with running water quickly, shake it well, and dilute it in a 250mL volumetric flask with pure water. Then take 2mL of the above clear solution and place it in a 250mL plastic volumetric flask, add 20mL NH 4 Cl-HCl buffer solution and 5mL of 2wt% ammonium molybdate were added, followed by adding 2mL of 2% ascorbic acid, and distilled to volume with pure water. After standing still until the silicon molybdenum yellow in the solution turns into silicon molybdenum blue, take an appropriate amount of stable color liquid and pour i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com