Static chuck mechanism and semiconductor processing equipment

An electrostatic chuck and electrostatic heating technology, which is applied in the direction of metal processing equipment, semiconductor/solid-state device manufacturing, metal processing machinery parts, etc., can solve the problem of uneven temperature in the edge area and center area of the wafer, the inability of the heater to control the temperature, and the inability to meet Etching uniformity and other issues to achieve the effect of improving process uniformity and heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order for those skilled in the art to better understand the technical solutions of the present invention, the electrostatic chuck mechanism and semiconductor processing equipment provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

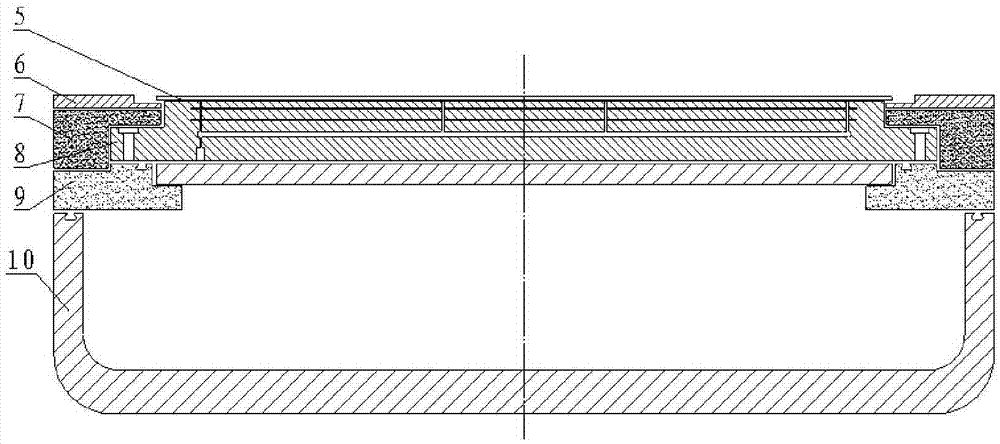

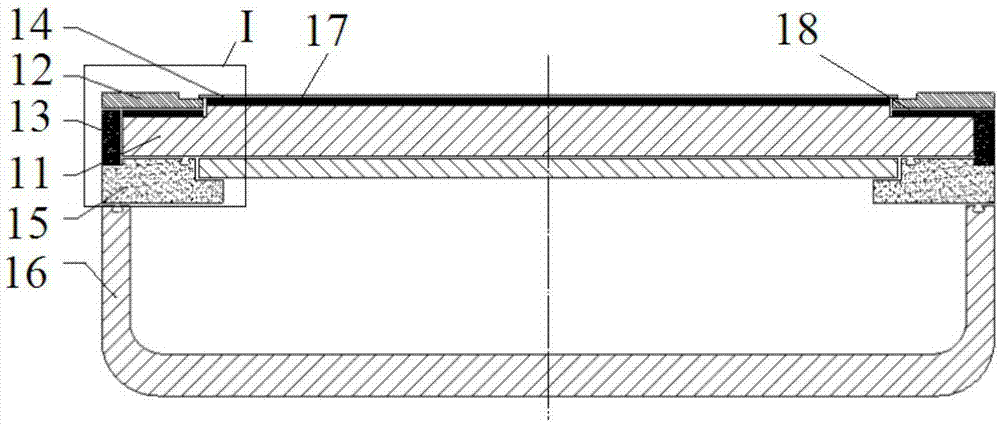

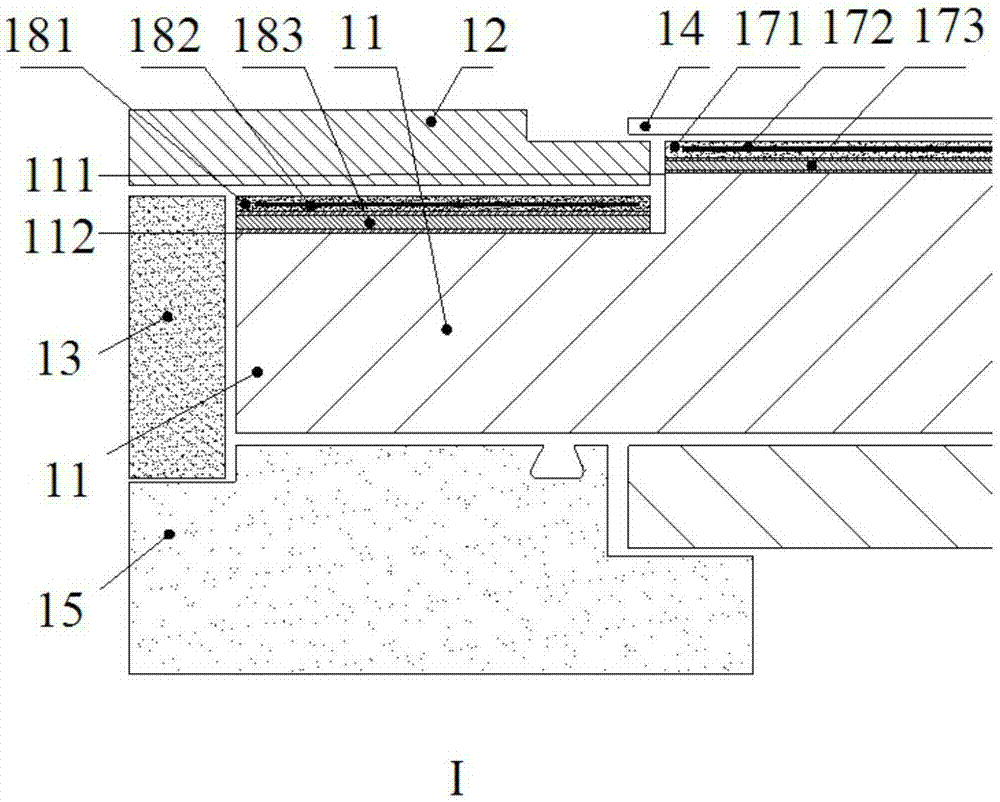

[0025] figure 2 A cross-sectional view of an electrostatic chuck mechanism provided by an embodiment of the present invention. image 3 for figure 2 Zoom-in view of the middle I region. Please also refer to figure 2 with image 3 , the electrostatic chuck mechanism includes a base 11 , an edge component, a main body electrostatic heating layer 17 and an edge electrostatic heating layer 18 . Wherein, the base 11 includes a carrying surface 111 for carrying the wafer 14 , and a stepped surface 112 surrounding the carrying surface 111 and located at an edge of the wafer 14 , and the stepped surface 112 is lower than the carrying surface 111 . That is to say, a boss is for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com