Oxygen reduction catalyst as well as preparation method and application thereof

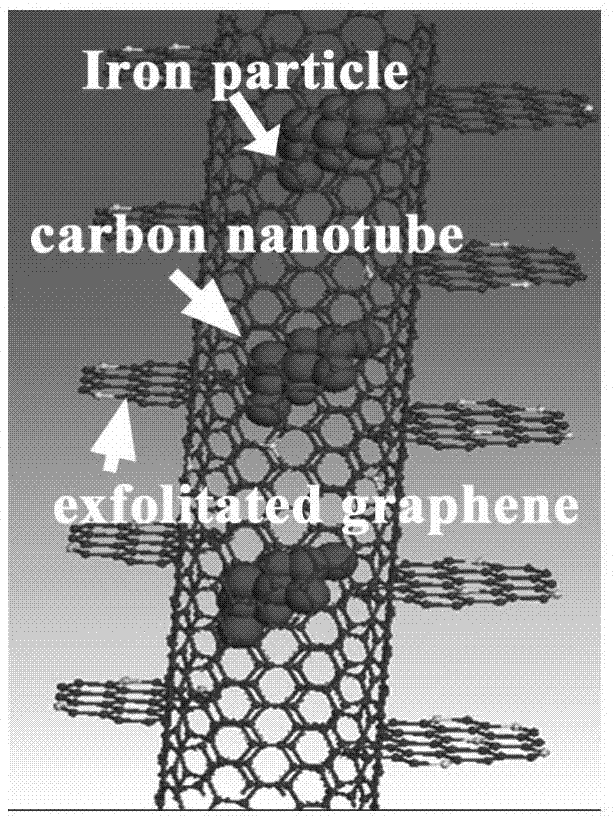

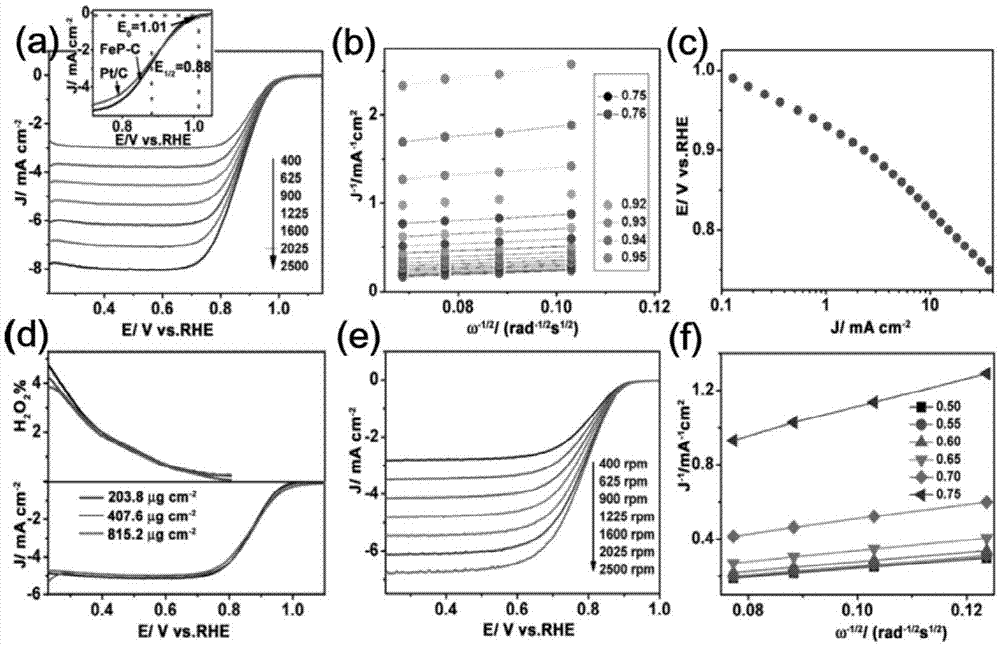

A catalyst and outer layer technology, which is applied in the field of preparation of non-platinum catalysts and non-platinum oxygen reduction catalysts, can solve problems such as the activity and stability of iron-based non-platinum catalysts, and achieve the effect of improving stability and catalyst activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

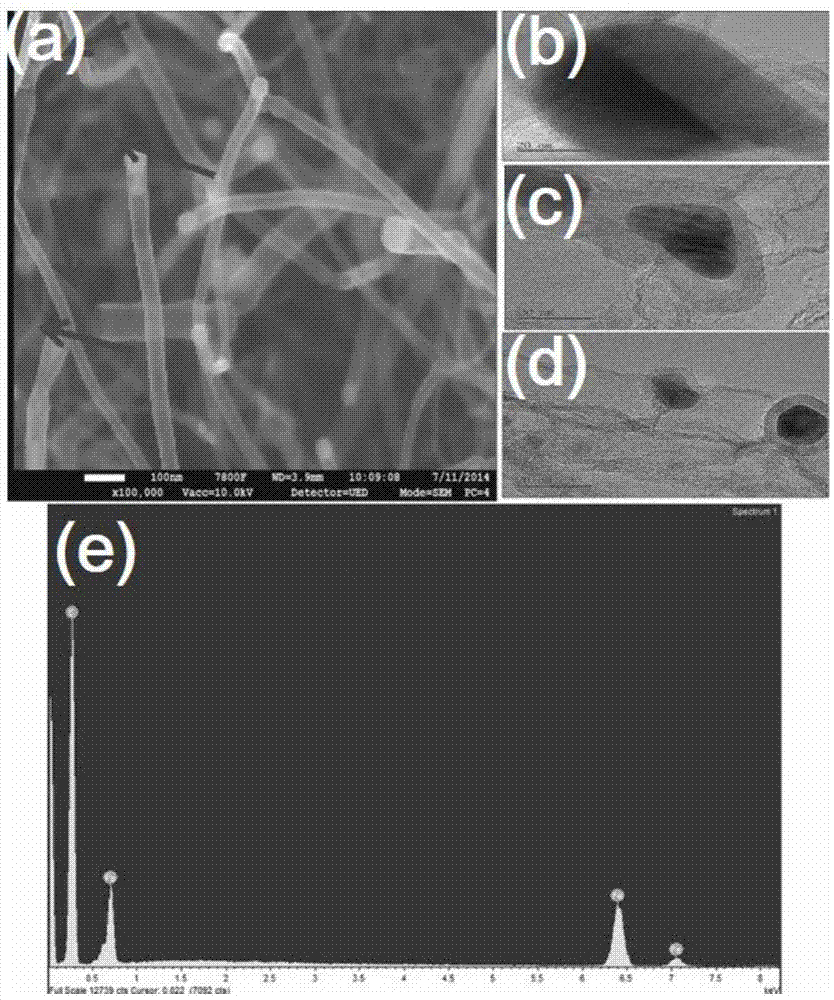

[0025] A preparation method of non-platinum oxygen reduction catalyst, comprising the following steps,

[0026] (a) Add melamine, glucose and ferric chloride with a molar ratio of 20:1:0.01 into deionized water at 95°C, stir until completely dissolved to obtain a mixed solution; stir until evenly mixed, and then dry the solid powder by rotary evaporation;

[0027] (b) In a tube furnace, under the protection of nitrogen, raise the temperature to 600°C at 5°C / min, hold for 2 hours, then raise the temperature to 900°C at 5°C / min, hold for 2 hours, take out the carbon package after cooling Nanomaterials with metallic structures.

[0028] (c) Take 200 mg of the sample obtained in step 2, add 10 mL of phosphoric acid / sulfuric acid (V / V=3:7) mixed acid solution, stir in ice bath for 2 hours, add 100 mg of potassium permanganate, and then After stirring for 1 hour at bath temperature, wash, filter, and dry;

[0029] (d) Raise the temperature of the sample obtained in step c to 900°C...

Embodiment 2

[0034] A preparation method of non-platinum oxygen reduction catalyst, comprising the following steps,

[0035] (a) Add melamine, glucose and cobalt acetate in a molar ratio of 10:1:0.02 to deionized water at 95°C, stir until completely dissolved to obtain a mixed solution; stir until evenly mixed, and then dry the solid powder by rotary evaporation;

[0036] (b) In a tube furnace, under the protection of nitrogen, raise the temperature to 600°C at 5°C / min, keep it for 2 hours, then raise the temperature to 900°C at 5°C / min, keep it for 2 hours, take out the carbon package after cooling Nanomaterials with metallic structures.

[0037] (c) Take 200 mg of the sample obtained in step 2, add 10 mL of phosphoric acid / sulfuric acid (V / V=3:7) mixed acid solution, stir at ice bath temperature for 2 hours, add 100 mg of potassium permanganate, and then After stirring for 1 hour at ice bath temperature, wash, filter, and dry;

[0038] (d) Raise the temperature of the sample obtained i...

Embodiment 3

[0040] A preparation method of non-platinum oxygen reduction catalyst, comprising the following steps,

[0041] (a) Add melamine, glucose and nickel acetate in a molar ratio of 10:1:0.02 to deionized water at 95°C, stir until completely dissolved to obtain a mixed solution; stir until evenly mixed, and then dry the solid powder by rotary evaporation;

[0042] (b) In a tube furnace, under the protection of nitrogen, raise the temperature to 600°C at 5°C / min, keep it for 2 hours, then raise the temperature to 900°C at 5°C / min, keep it for 2 hours, take out the carbon package after cooling Nanomaterials with metallic structures.

[0043] (c) Take 200 mg of the sample obtained in step 2, add 10 mL of phosphoric acid / sulfuric acid (V / V=3:7) mixed acid solution, stir at ice bath temperature for 2 hours, add 100 mg of potassium permanganate, and then After stirring for 1 hour at ice bath temperature, wash, filter, and dry;

[0044] (d) Raise the temperature of the sample obtained i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com