Semiconductor laser side-coupled axial pumped alkali metal laser

A side-coupling, alkali metal technology, applied in the laser field, can solve the problems of difficult to obtain mode matching, low laser optical efficiency, etc., and achieve the effect of low processing difficulty, long gain length, and good mode matching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

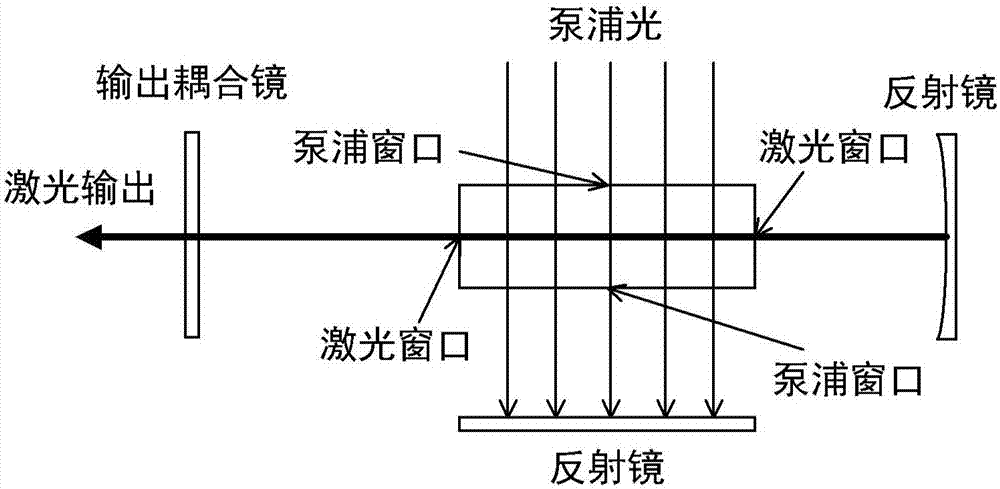

[0045] Such as Figure 4 As shown, this embodiment proposes an alkali metal laser with semiconductor laser side-coupled axial pumping, including three semiconductor pump sources 1, an alkali metal vapor chamber 2 and a resonant cavity, and also includes three steering elements 5, The three steering elements 5 correspond to the three semiconductor pump sources 1 one by one, and are used to change the propagation direction of the pump light emitted by the three semiconductor pump sources; the pump light emitted by the three semiconductor pump sources is in the alkali metal The vapor chamber 2 ends up with paraxial light.

[0046] Wherein, the resonant cavity includes a reflecting mirror 3 and an output coupling mirror 4, and the alkali metal vapor chamber 2 is placed between the reflecting mirror 3 and the output coupling mirror 4; the three diverting elements 5 adopt a full-reflective concave mirror with a hole in the center , the diameter of the central hole is greater than t...

Embodiment 2

[0049] Such as Figure 5 As shown, this embodiment proposes an alkali metal laser with semiconductor laser side-coupled axial pumping, including five semiconductor pump sources 1, an alkali metal vapor chamber 2 and a resonant cavity, and also includes five steering elements 5, The five steering elements 5 correspond to the five semiconductor pump sources 1 one by one, and are used to change the propagation direction of the pump light emitted by the five semiconductor pump sources; the pump light emitted by the five semiconductor pump sources is in the alkali metal The vapor chamber 2 ends up with paraxial light.

[0050] Wherein, the resonant cavity includes a reflecting mirror 3 and an output coupling mirror 4, and the alkali metal vapor chamber 2 is placed between the reflecting mirror 3 and the output coupling mirror 4; the five diverting elements 5 adopt a full-reflective concave mirror with a hole in the center , the diameter of the central hole is greater than the size...

Embodiment 3

[0053] Such as Figure 6 As shown, this embodiment proposes an alkali metal laser with semiconductor laser side-coupled axial pumping, including 4 semiconductor pump sources 1, 1 alkali metal vapor chamber 2 and a resonant cavity, and also includes 4 steering elements 5, The four steering elements 5 correspond to the four semiconductor pump sources 1 one by one, and are used to change the propagation direction of the pump light emitted by the four semiconductor pump sources; the pump light emitted by the four semiconductor pump sources is in the alkali metal The vapor chamber 2 ends up with paraxial light. .

[0054] Wherein, the resonant cavity includes a reflecting mirror 3 and an output coupling mirror 4, and the alkali metal vapor chamber is placed between the reflecting mirror 3 and the output coupling mirror 4; the four diverting elements 5 adopt a full-reflective concave mirror with a hole in the center, The diameter of the central hole is greater than the size of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com