Warping prediction and optimization method in aluminum alloy plate asymmetrical rolling

A technology for asynchronous rolling and alloy plates, applied in metal rolling, design optimization/simulation, contour control, etc., to achieve the effect of improving the quality of the plate shape and avoiding the transformation of rolling equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

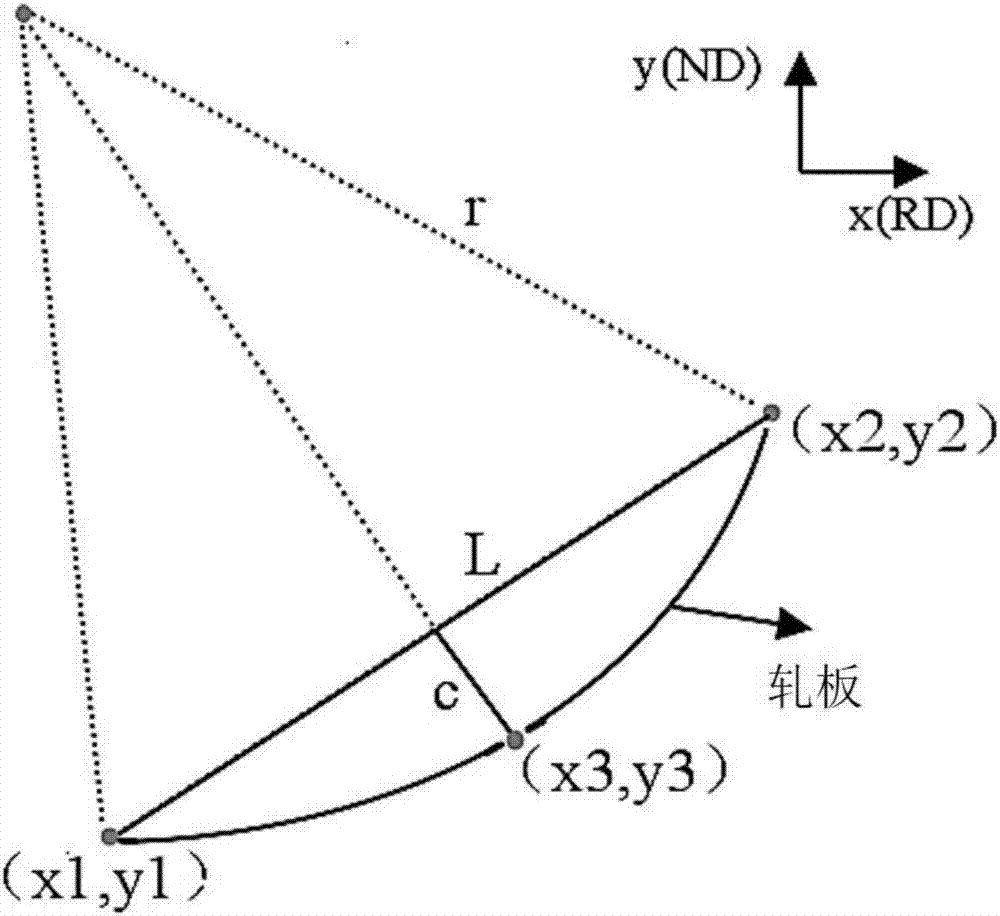

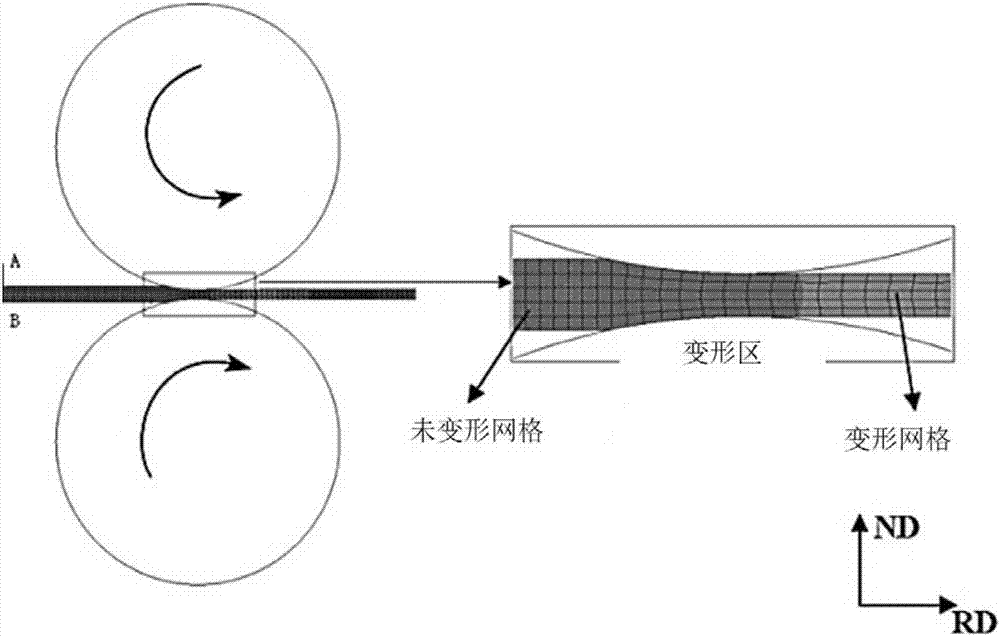

[0055] In order to improve or solve the warping problem of asynchronously rolled aluminum alloy medium and thick plates, firstly, a two-dimensional plane strain model of asynchronous rolling was established by using finite element simulation analysis software (such as figure 2 shown), specifically include the following steps:

[0056] Step 1. Establishment of geometric and material models: the upper and lower rolls in the model are simplified to an ideal rigid-plastic model, the diameter of the upper and lower rolls is 400mm, the speed of the upper roll is 1m / s, and the speed of the lower roll is 1.2m / s, corresponding to different speeds Ratio is 1.2; Define the material performance parameter of rolling plate in the simulation process, as the specific heat of material under different temperature conditions, thermal conductivity, Poisson's ratio etc. , etc. Finite element simulation of aluminum alloy thick plate quenching residual stress and its influence on processing deforma...

Embodiment 2

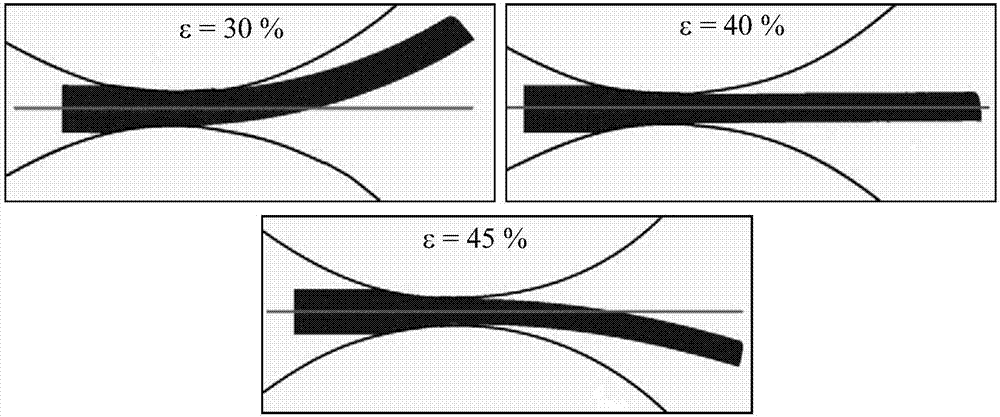

[0067] A 7050 aluminum alloy plate with an initial thickness of 40 mm was used to carry out experimental rolling using the non-warping asynchronous rolling process simulated in the present invention, and the experimental rolling parameters were the same as those set in the simulation. After obtaining the experimental rolled plate, measure the warpage curvature of the rolled plate, the measured value is as follows Figure 5 shown. Compared with the simulation results, the measured critical reduction is basically consistent with the simulation results, indicating that the above method can accurately and reliably predict the warpage of 7050 aluminum alloy plate under different asynchronous rolling conditions.

[0068] Table 1 further shows the simulated calculation results and experimental results of the plate thickness and critical pass reduction of the 40mm thick 7050 aluminum alloy plate under the condition of different speed ratio of 1.2 after different passes of asynchronous...

Embodiment 3

[0070]The above examples prove that asynchronous rolling without warpage can be achieved by using the critical pass reduction method. However, due to the limitation of the rolling capacity of the rolling mill in actual production, not all initial thicknesses can pass the above critical pass reduction. method to achieve warpage optimization. Therefore, it is necessary to obtain the maximum rollable initial plate thickness that can achieve warpage optimization by using the critical pass reduction method based on the common rolling mill equipment conditions in the existing industrial production. According to the rolling bite condition, the relationship between the bite angle (α) and the friction coefficient (μ) needs to be satisfied: αmax and maximum bite angle α max There is a relationship between: Δh max =2R(1-cosα max ). Using the friction coefficient 0.35 given above and the work roll radius 600mm to calculate, it can be known that the maximum reduction Δh that the rolling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com