Preparation method of magnetic superhydrophobic ethyl cellulose sponge for oil-water separation

A technology of cellulose sponge and ethyl cellulose, applied in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve problems such as secondary pollution, refractory degradation, and environmental pollution, and achieve Effect of high oil-water separation efficiency, high oil-water separation ability, and strong oil-water separation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

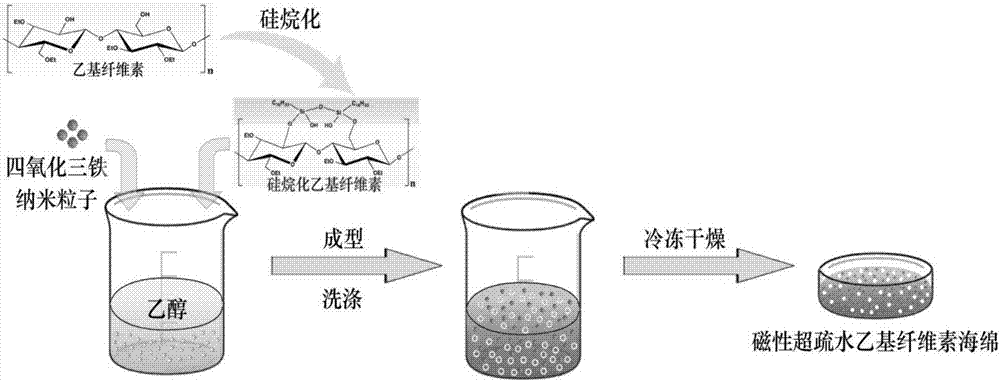

[0028] A preparation method for a magnetic superhydrophobic ethyl cellulose sponge for oil-water separation, comprising the following process steps:

[0029] (1) Preparation of silane hydrophobized modified ethyl cellulose:

[0030] Add 1.3 mL of hexadecyltrimethoxysilane (HDTMS) and 4 mL of deionized water to 30 mL of absolute ethanol, stir magnetically for 30 min, then add 1 mL of glacial acetic acid (HAc), and continue stirring for 30 min. Put the reaction device into a 60°C oil bath and connect a spherical condenser, and perform hydrolysis for 60 minutes to obtain HDTMS hydrolyzate. Add 1.2g of ethyl cellulose to the prepared HDTMS hydrolyzate, stir and react at 60°C for 4 hours, take out the flask, wash repeatedly with deionized water to remove solvent and residual glacial acetic acid, and dry to obtain silanized modified Ethyl cellulose.

[0031] (2) Preparation of magnetic Fe3O4 nanoparticles coated with oleic acid:

[0032] Under the protection of high-purity argon,...

Embodiment 2

[0040] A preparation method for a magnetic superhydrophobic ethyl cellulose sponge for oil-water separation, comprising the following process steps:

[0041] (1) Preparation of silane hydrophobized modified ethyl cellulose:

[0042] Add 2.0 mL of hexadecyltrimethoxysilane (HDTMS) and 6 mL of deionized water to 30 mL of absolute ethanol, stir magnetically for 30 min, then add 1 mL of glacial acetic acid (HAc), and continue stirring for 30 min. Put the reaction device into an oil bath at 65°C and connect it with a spherical condenser, and perform a hydrolysis reaction for 60 minutes to obtain HDTMS hydrolyzate. Add 1.8g of ethyl cellulose to the prepared HDTMS hydrolyzate, stir and react at 60°C for 6 hours, take out the flask, wash repeatedly with deionized water to remove solvent and residual glacial acetic acid, and dry to obtain silanized modified Ethyl cellulose.

[0043] (2) Preparation of magnetic Fe3O4 nanoparticles coated with oleic acid:

[0044] Under the protectio...

Embodiment 3

[0052] A preparation method for a magnetic superhydrophobic ethyl cellulose sponge for oil-water separation, comprising the following process steps:

[0053] (1) Preparation of silane hydrophobized modified ethyl cellulose:

[0054] Add 2.2 mL of hexadecyltrimethoxysilane (HDTMS) and 4.5 mL of deionized water to 40 mL of absolute ethanol, stir magnetically for 30 min, then add 2.5 mL of glacial acetic acid (HAc), and continue stirring for 30 min. Put the reaction device into an oil bath at 65°C and connect it with a spherical condenser, and perform a hydrolysis reaction for 60 minutes to obtain HDTMS hydrolyzate. Add 1.2g of ethyl cellulose to the prepared HDTMS hydrolyzate, stir and react at 60°C for 4 hours, take out the flask, wash repeatedly with deionized water to remove solvent and residual glacial acetic acid, and dry to obtain silanized modified Ethyl cellulose.

[0055] (2) Preparation of magnetic Fe3O4 nanoparticles coated with oleic acid:

[0056] Under the prote...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Separation efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com