A method for extracting, separating and purifying blueberry anthocyanins

A technology for the separation and purification of blueberry anthocyanins, which is applied in the field of extracting, separating and purifying blueberry anthocyanins using normal temperature and high pressure homogenization technology, can solve problems such as high equipment cost, insufficient product quality and market competitiveness, and poor safety, and achieve Rapid results of separation and purification methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

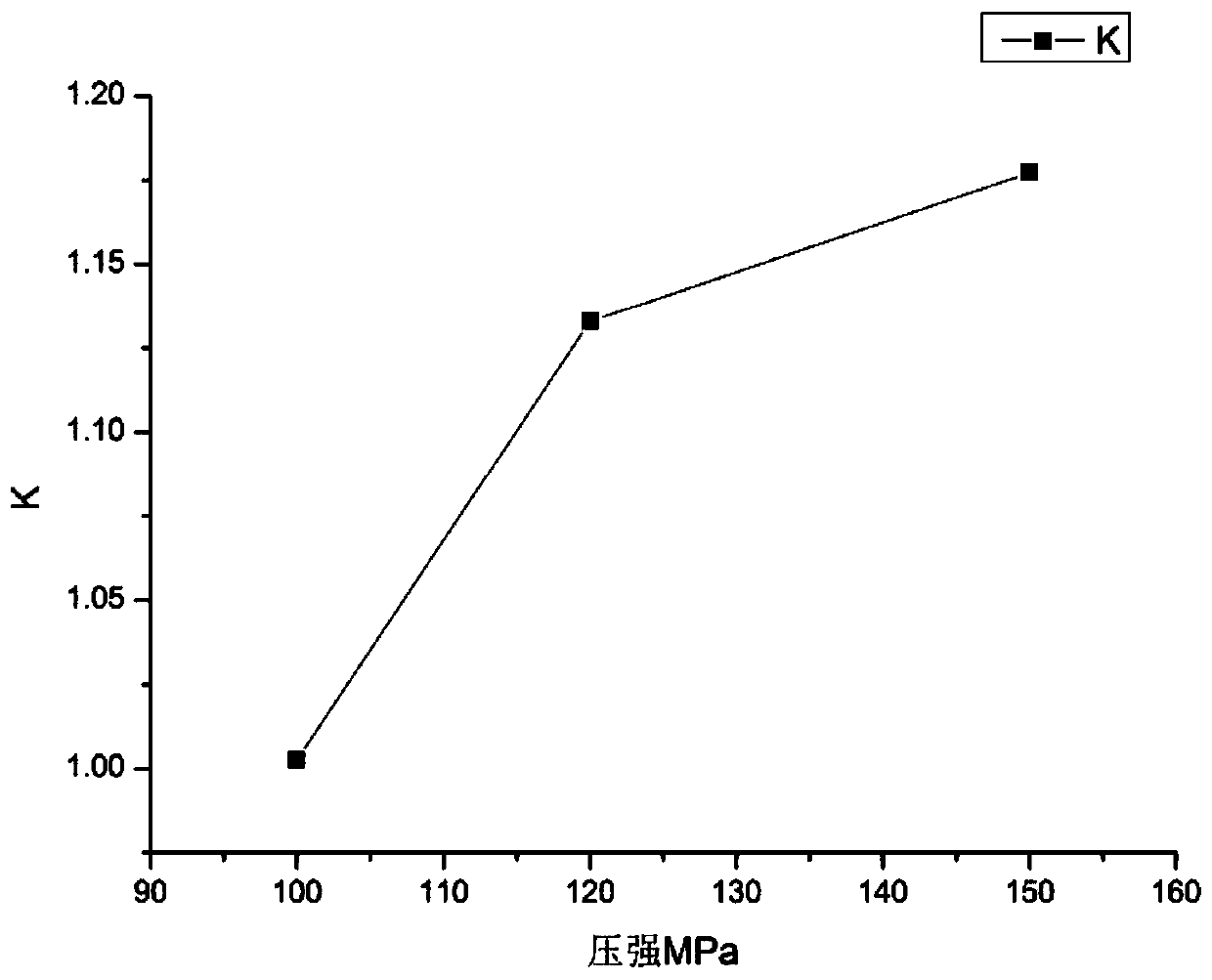

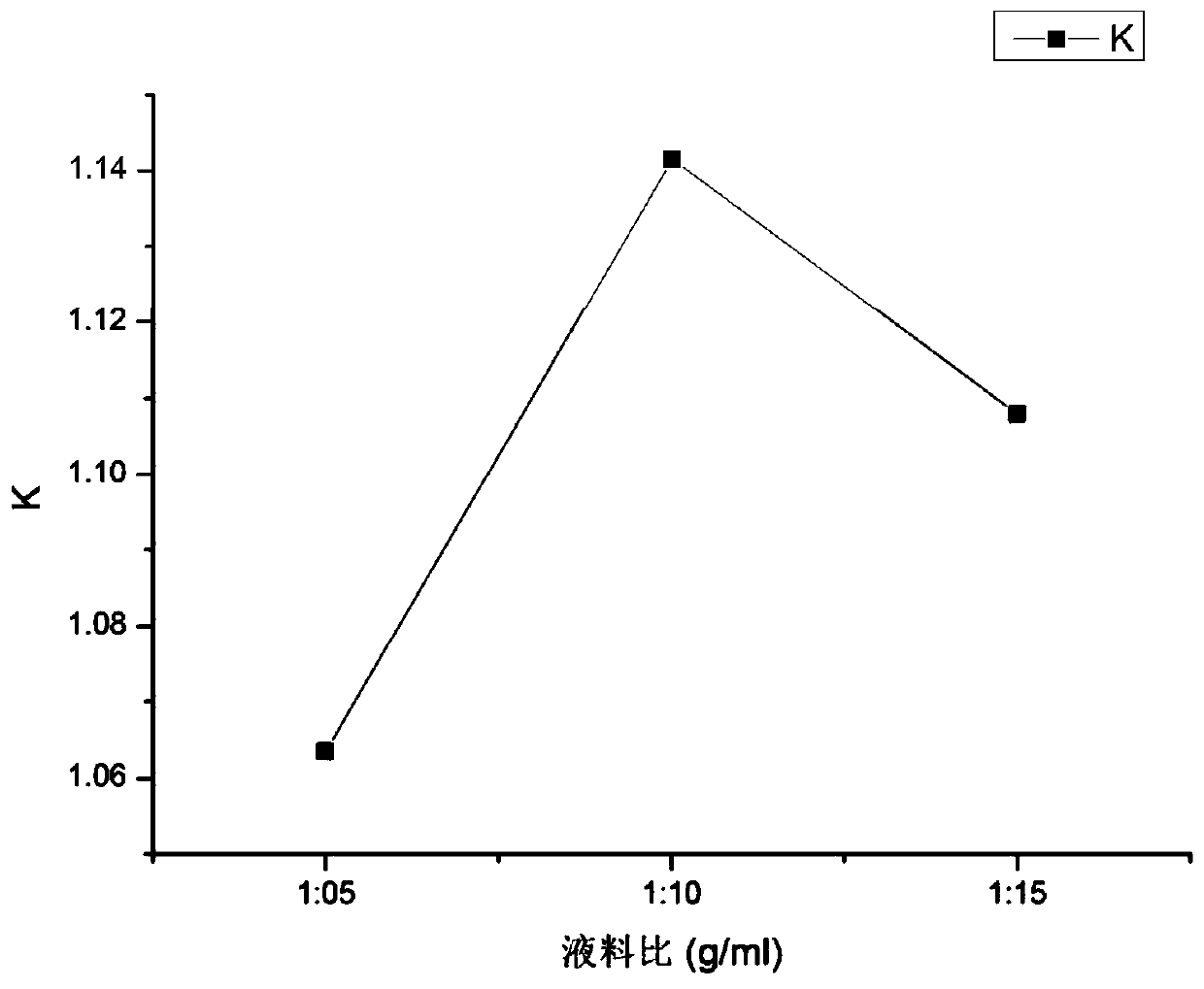

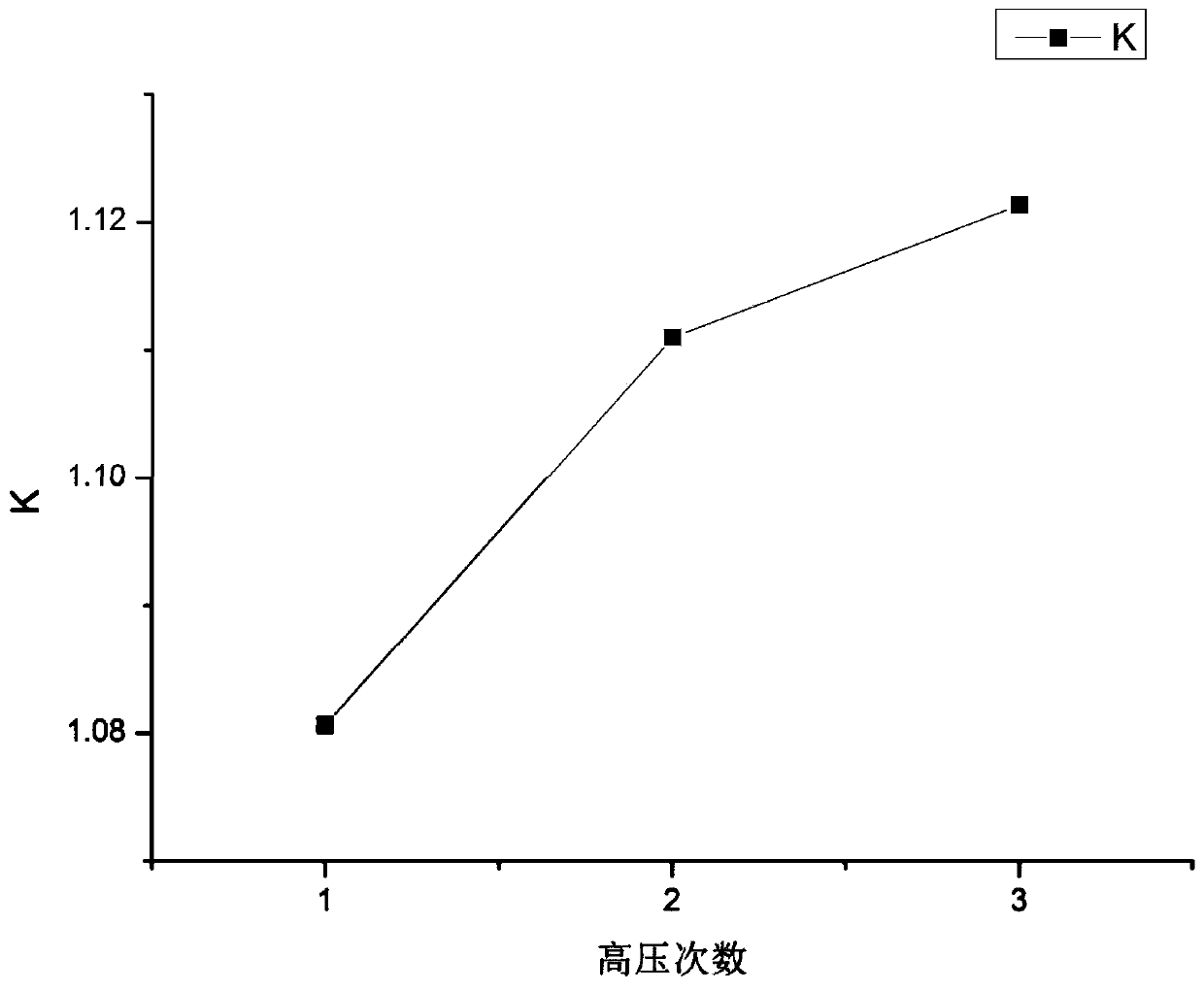

[0063] Example 1 Blueberry anthocyanin extraction process research

[0064] Taking blueberry anthocyanins as the measurement index, taking extraction pressure, solid-liquid ratio, and extraction times as the investigation index factors, the extraction efficiency of blueberry anthocyanins was systematically investigated. First, the effects of pressure, solid-liquid ratio, and extraction times on the anthocyanin Extract content single factor experiment, then conduct L9(3 3 ) content orthogonal experimental design, optimize the extraction process at room temperature and high pressure. Find out the primary and secondary order of blueberry anthocyanin extraction rate, and propose the optimal extraction scheme.

[0065] 3.1 Orthogonal experiment

[0066] The fixed blueberry juice sample mass is 10.0 g, the solution pH is 1.0, and the extractant is 80% ethanol solution. Select pressure, material-liquid ratio, and number of experiments as the influencing factors, and design an orth...

Embodiment 2

[0114] Example 2 Research on the separation and purification method of blueberry anthocyanins

[0115] The crude extract of blueberry anthocyanins was purified by using silica gel, polyamide resin, and HPD600 macroporous adsorption resin as fillers for column chromatography. Taking the anthocyanin content and anthocyanin yield in each gradient eluent obtained from different resins as the measurement index, the column chromatography filler for purifying anthocyanin was screened. In this experiment, ethanol solution was used as the eluent.

[0116] 4.1 Resin pretreatment

[0117] Silica gel: Chromatographic silica gel should be neutral and colorless particles, but because the production process is often acidic, you should also check whether it contains iron ions. a. Iron ion inspection: Take an appropriate amount of silica gel, suspend it in hydrochloric acid, stir, if it contains iron ions, it will combine with hydrochloric acid to form a complex and appear yellow. At this tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com