Dispersing agent and preparation method thereof

A technology of dispersant and initiator, which is applied in the field of dispersant for chlorinated polyethylene and its preparation, can solve problems such as condensation kettle and large HLB, and achieve the effects of lower reaction temperature, low solid content, and reduced amount of coarse material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

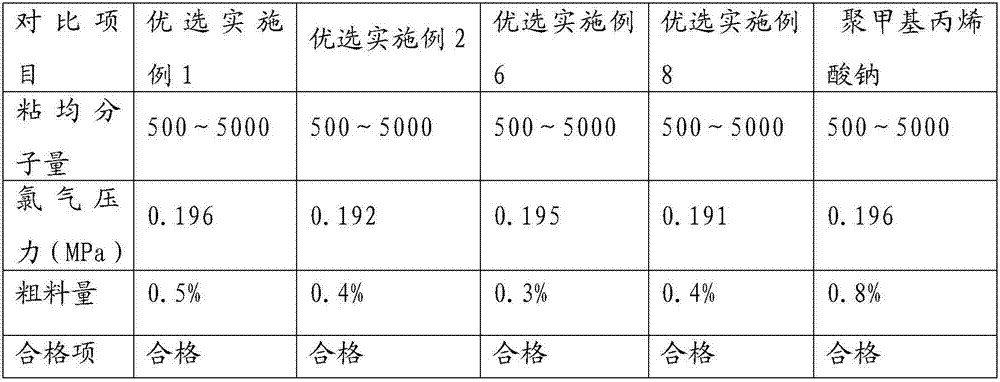

Examples

Embodiment 1

[0027] Add 500~700Kg of water, 0.1~8Kg of sodium oleate, 100~200Kg of acrylic acid, heat to 40℃~70℃, add initiator and comonomer methyl methacrylate 10~60Kg dropwise in a 1-ton reactor , React at 70℃~90℃ for 20~60 minutes. Cool down to 40°C and discharge.

[0028] After testing, its viscosity average molecular weight is: 500~5000

Embodiment 2

[0030] Add 500~700Kg of water to a 1 ton reaction kettle, add 0.1~8Kg of K12, 100~200Kg of acrylic acid, and heat to 30℃~70℃. Add initiator and comonomer methyl methacrylate 10~ 60Kg, at 70℃~90℃, react for 20~60 minutes. Cool down to 40°C and discharge.

[0031] After testing, its viscosity average molecular weight is: 500~5000

Embodiment 3

[0033] Add 500~700Kg of water to a 1 ton reaction kettle, add 0.1~8Kg of ABS-Na, 100~200Kg of acrylic acid, heat to 40℃~70℃, add the initiator and comonomer methyl methacrylate dropwise in turn 10~60Kg, at 70℃~90℃, react for 20~60 minutes. Cool down to 40°C and discharge.

[0034] After testing, its viscosity average molecular weight is: 500~5000

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com