Organic engine cooling liquid containing carboxylated fullerene and preparation method thereof

A carboxylated fullerene and engine coolant technology, which is applied in the field of engine coolant, can solve the problems of solder and aluminum alloys with unsatisfactory anti-corrosion effects and non-compactness, and achieve long service life, slow consumption, and good compatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

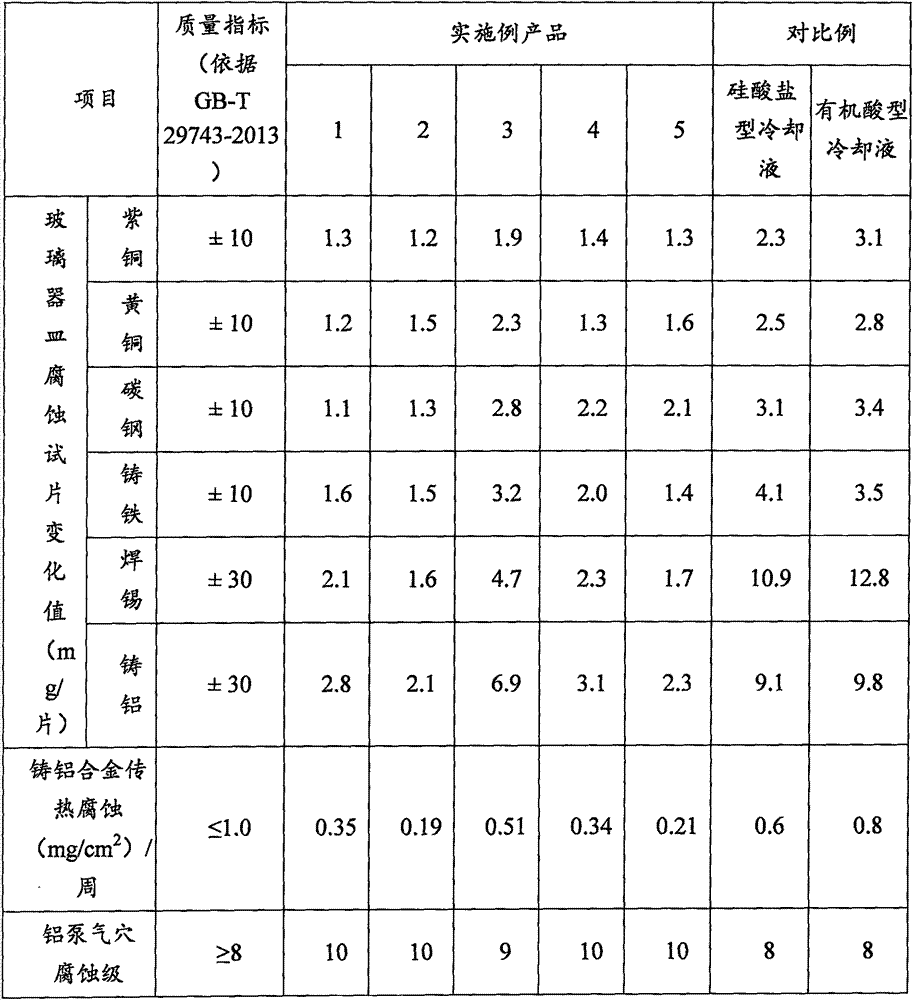

Examples

Embodiment 1

[0046] Mix and stir 48kg ethylene glycol and 52kg distilled water evenly to obtain the cooling liquid base liquid; add 1.5 kg isooctanoic acid, 1.0 kg sebacic acid, and 0.1 kg acetate fullerene to the above base liquid, and stir until completely dissolved to obtain the first 1 mixed solution; add 0.12kg of tolyl benzotriazole to the first mixed solution, fully stir until completely dissolved to obtain the second mixed solution; add 0.005kg of organic silicon defoamer to the second mixed solution, fully stir , to completely dissolve until a clear and transparent solution is obtained; add 0.02kg of acid lake blue dye to the above-mentioned clear and transparent mixed solution, stir well until completely dissolved, and finally obtain the cooling liquid product 1.

[0047] The composition of coolant product 1 is: ethylene glycol 48kg, distilled water 52kg, acetate fullerene 0.1kg, isooctanoic acid 1.5kg, sebacic acid 1.0kg, methyl benzotriazole 0.12kg, silicone defoamer 0.005kg, a...

Embodiment 2

[0049] Mix and stir 95kg propylene glycol and 5kg distilled water evenly to obtain the cooling liquid base liquid; add 1.8kg adipic acid, 3.2kg n-octanoic acid, 0.8kg acetate fullerene, and 0.2 adipic acid fullerene to the above base liquid and stir fully until Completely dissolve to obtain the first mixed solution; add 0.5kg of benzotriazole to the first mixed solution, stir until completely dissolved to obtain the second mixed solution; add 0.01kg of organic silicon defoamer to the second mixed solution, Stir fully to dissolve completely until a clear and transparent solution is obtained; add 0.05kg bright yellow dye to the above clear and transparent solution, stir until completely dissolved, and finally obtain the cooling liquid product 2.

[0050] The composition of coolant product 2 is: propylene glycol 95kg, distilled water 5kg, acetate fullerene 0.8kg, adipic fullerene 0.2kg, n-octanoic acid 3.2kg, adipic acid 1.8kg, benzotriazole 0.5kg, organic Silicon defoamer 0.01kg...

Embodiment 3

[0052] Mix and stir 30kg of ethylene glycol and 70kg of distilled water evenly to obtain a cooling liquid base liquid; add 0.22kg of adipic acid, 0.28kg of n-heptanoic acid, and 0.01kg of propionated fullerene to the above base liquid, and stir until completely dissolved to obtain The first mixed solution; add 0.01kg tolyl benzotriazole in the first mixed solution, fully stir until fully dissolved to obtain the second mixed solution; add 0.001kg organic ether defoamer in the second mixed solution, fully Stir to completely dissolve until a clear and transparent solution is obtained; add 0.01 kg of rose bengal dye to the above-mentioned clear and transparent solution, stir well until completely dissolved, and finally obtain cooling liquid product 3.

[0053] The composition of coolant product 3 is: ethylene glycol 30kg, distilled water 70kg, propionated fullerene 0.01kg, n-heptanoic acid 0.28kg, adipic acid 0.22kg, methylbenzotriazole 0.01kg, organic ether defoaming Agent 0.001k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com