Clay stabilizing agent capable of preventing water-sensitivity damage and preparation method thereof

A technology of clay stabilizer and surfactant, which is applied in the field of waterproof and sensitive clay stabilizer and its preparation, can solve the problems of cracking catalyst deactivation, etc., and achieve the effects of improving use efficiency, simple synthesis process, and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1: Clay Stabilizer D 1 and its preparation method

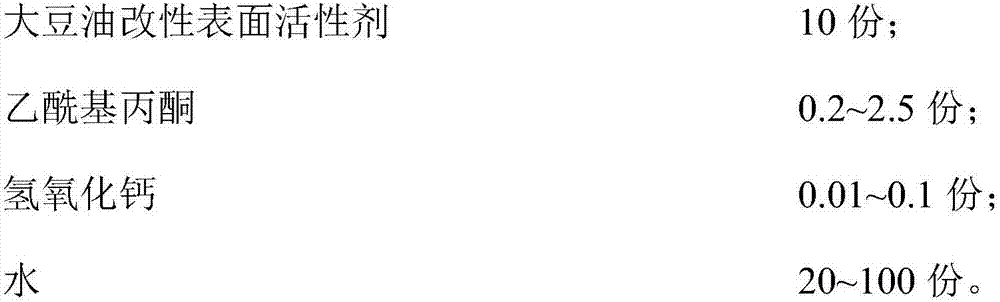

[0032] (1) Clay Stabilizer D 1 The composition and components are as follows:

[0033]

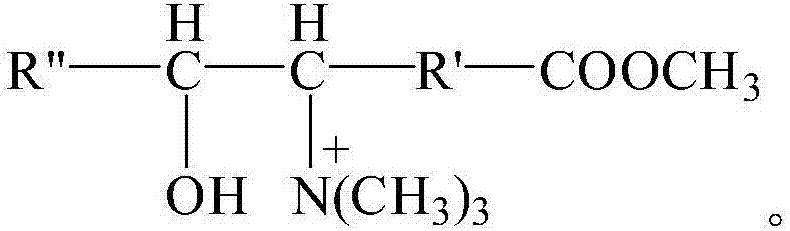

[0034] According to existing literature, the synthetic route of described soybean oil modified surfactant is as follows:

[0035]

[0036] Among them: R″ is C n h 2n+1 , 0≤n≤15; R' is C m h 2m+1 , 0≤m≤15.

[0037] (2) Clay Stabilizer D 1 The preparation method is as follows:

[0038] ①Put 20 parts of water into the beaker, heat the beaker in a constant temperature water bath at 60°C, add 0.2 parts of acetylacetone at a stirring rate of 200 rpm, and continue stirring for 15 minutes to obtain a mixed solution;

[0039] ② Adjust the temperature of the above mixed solution to 28°C. After the temperature is constant, slowly add 0.01 part of calcium hydroxide at a stirring rate of 500rpm. After adding it completely, continue stirring for 20 minutes, then raise the temperature to 60°C, and keep the temperature cons...

Embodiment 2

[0041] Example 2: Clay Stabilizer D 2 and its preparation method

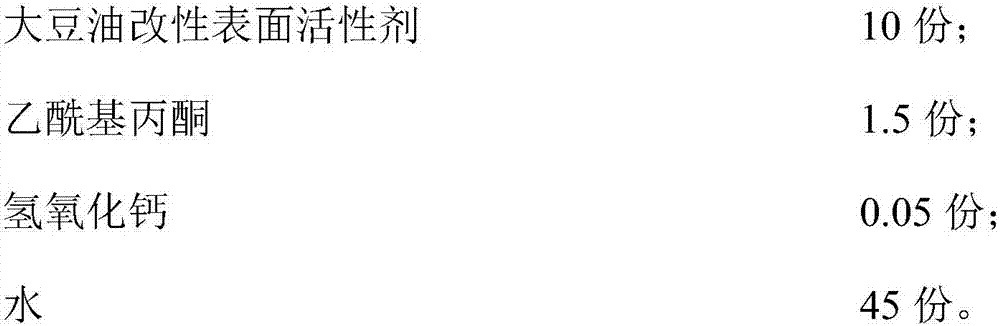

[0042] (1) Clay Stabilizer D 2 The composition and components are as follows:

[0043]

[0044] According to existing literature, the synthetic route of described soybean oil modified surfactant is as follows:

[0045]

[0046] Among them: R″ is C n h 2n+1 , 0≤n≤15; R' is C m h 2m+1 , 0≤m≤15.

[0047] (2) Clay Stabilizer D 2 The preparation method is as follows:

[0048] ①Put 45 parts of water into the beaker, heat the beaker in a constant temperature water bath at 65°C, add 1.5 parts of acetylacetone at a stirring rate of 300 rpm, and continue stirring for 20 minutes to obtain a mixed solution;

[0049] ② Adjust the temperature of the above mixed solution to 32°C. After the temperature is constant, slowly add 0.05 parts of calcium hydroxide at a stirring rate of 530rpm. After adding it completely, continue stirring for 25 minutes, then raise the temperature to 75°C, and keep the temperature const...

Embodiment 3

[0051] Example 3: Clay Stabilizer D 3 and its preparation method

[0052] (1) Clay Stabilizer D 3 The composition and components are as follows:

[0053]

[0054] According to existing literature, the synthetic route of described soybean oil modified surfactant is as follows:

[0055]

[0056] Among them: R″ is C n h 2n+1 , 0≤n≤15; R' is C m h 2m+1 , 0≤m≤15.

[0057] (2) Clay Stabilizer D 3 The preparation method is as follows:

[0058] ①Put 80 parts of water into the beaker, heat the beaker in a constant temperature water bath at 70°C, add 2.0 parts of acetylacetone at a stirring rate of 220rpm, and continue stirring for 25 minutes to obtain a mixed solution;

[0059] ② Adjust the temperature of the above mixed solution to 25°C. After the temperature is constant, slowly add 0.02 parts of calcium hydroxide at a stirring rate of 550rpm. After adding it completely, continue stirring for 20 minutes, then raise the temperature to 65°C, and keep the temperature cons...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com