Fluorescent material emitting yellow light under near-ultraviolet excitation, preparation method and application

A near-ultraviolet light and fluorescent material technology, applied in the field of fluorescent materials, can solve the problems of high cost in the preparation process, low stability and luminous efficiency, low color rendering index, etc., and achieves pure chromaticity, safe and reliable method. Control and improve the effect of color rendering index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

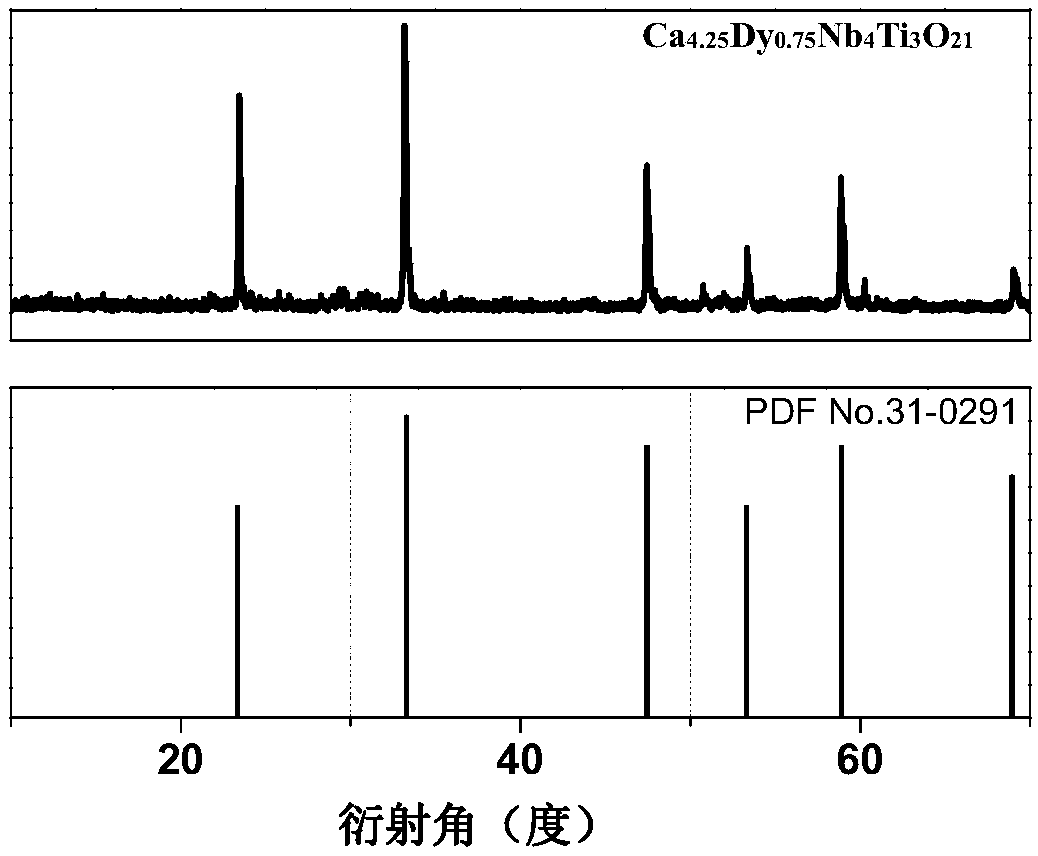

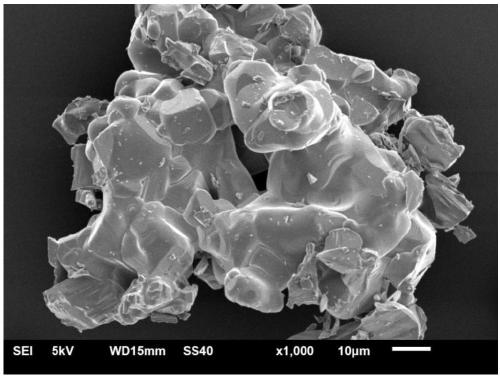

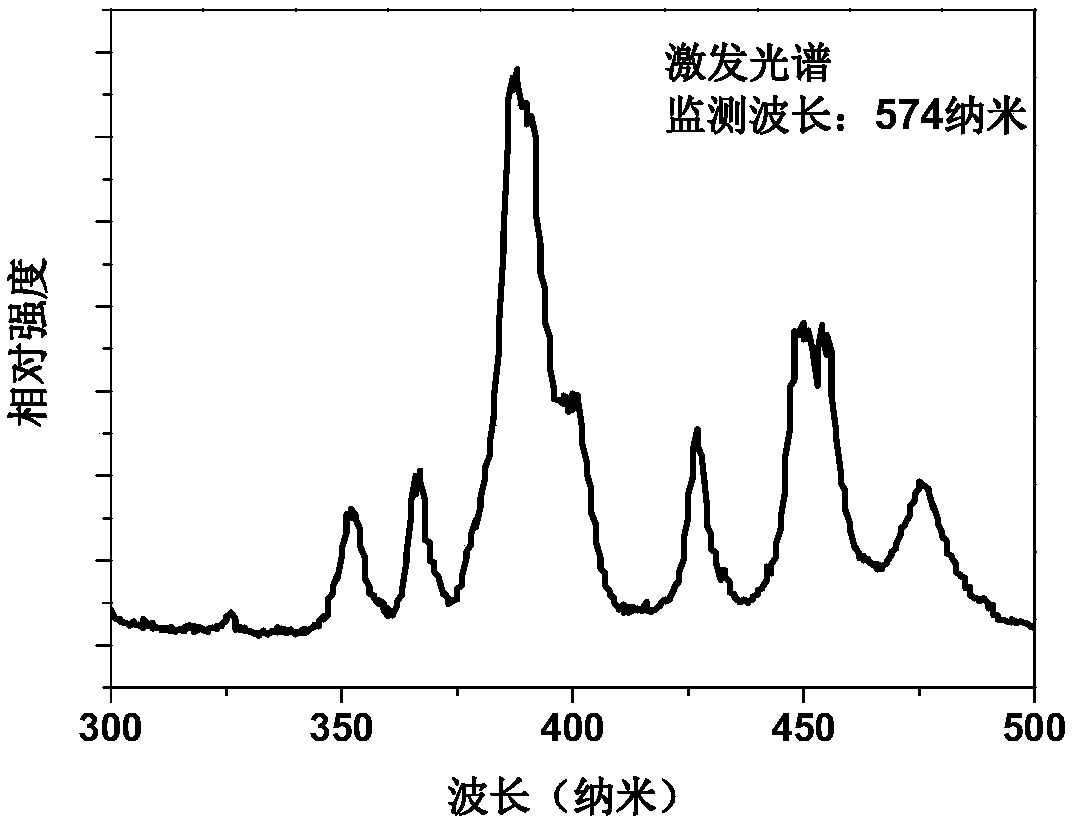

[0037] According to the chemical formula Ca 4.25 Dy 0.75 Nb 4 Ti 3 o 21 The stoichiometric ratio of each element in, respectively weighed calcium carbonate CaCO 3 : 2.1250 grams; dysprosium oxide Dy 2 o 3 : 0.6995 g; niobium pentoxide Nb 2 o 5 : 2.6580 g; Titanium dioxide TiO 2 : 1.1981 grams are the raw materials for preparation, the raw materials weighed are ground respectively, and mixed uniformly; the mixture obtained is pre-sintered for the first time under air atmosphere, and the pre-sintering temperature is 900 ° C, and the time is 10 hours; the sample after cooling is ground evenly Finally, the second pre-sintering in the air atmosphere, the pre-sintering temperature is 1200 ℃, the pre-sintering time is 1 hour; after the sample is cooled, it is ground and mixed evenly, and finally calcined in the air atmosphere, the calcination temperature is 1400 ℃, and the calcination time is 1 hour, get the trivalent dysprosium ion Dy 3+ Activated yellow phosphor.

[0038...

Embodiment 2

[0044] According to the chemical formula Ca 4.995 Dy 0.005 Nb 4 Ti 3 o 21 The stoichiometric ratio of each element in, respectively weighed calcium chloride CaCl 2 ::2.7722 g; Dy(NO 3 ) 3 ·6H 2 O: 0.0115 g; niobium pentachloride NbCl 5 : 5.4000 g; Titanium dioxide TiO 2 : 1.1981 grams is the raw material of preparation, the raw material that weighs is ground respectively, mixes uniformly; The mixture that obtains is pre-sintered under air atmosphere, and pre-sintering temperature is 1100 ℃, and pre-sintering time is 5 hours; Sintered sample grinds evenly, Calcined in an air atmosphere, the calcination temperature is 1200 ° C, and the calcination time is 15 hours, a trivalent dysprosium ion Dy 3+ Activated yellow phosphor.

[0045] The main structural properties, excitation spectrum, luminescence spectrum and luminescence lifetime spectrum of the sample are similar to those of Example 1.

Embodiment 3

[0047] According to the chemical formula Ca 4 wxya 4 Ti 3 o 21 The stoichiometric ratio of each element in is weighed respectively calcium oxide CaO: 1.1200 grams; dysprosium oxide Dy 2 o 3 : 0.9328 g; niobium pentoxide Nb 2 o 5 : 2.6580 g; Titanium dioxide TiO 2 : 1.1981 g is the raw material for preparation, the raw materials weighed are ground respectively and mixed uniformly; the mixture obtained is pre-sintered in an air atmosphere, the pre-sintering temperature is 1000 ° C, and the pre-sintering time is 8 hours; the sintered sample is ground evenly, Calcining again under air atmosphere, the calcination temperature is 1250°C, and the calcination time is 8 hours to obtain a trivalent dysprosium ion Dy 3+ Activated yellow phosphor.

[0048] The main structural properties, excitation spectrum, luminescence spectrum and luminescence lifetime spectrum of the sample are similar to those of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com