Method for preparing lysozyme by means of fermentation process

A fermentation process and lysozyme technology, applied in the field of bioengineering, can solve problems such as limited application, limited lysozyme activity, and less research on lysozyme activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

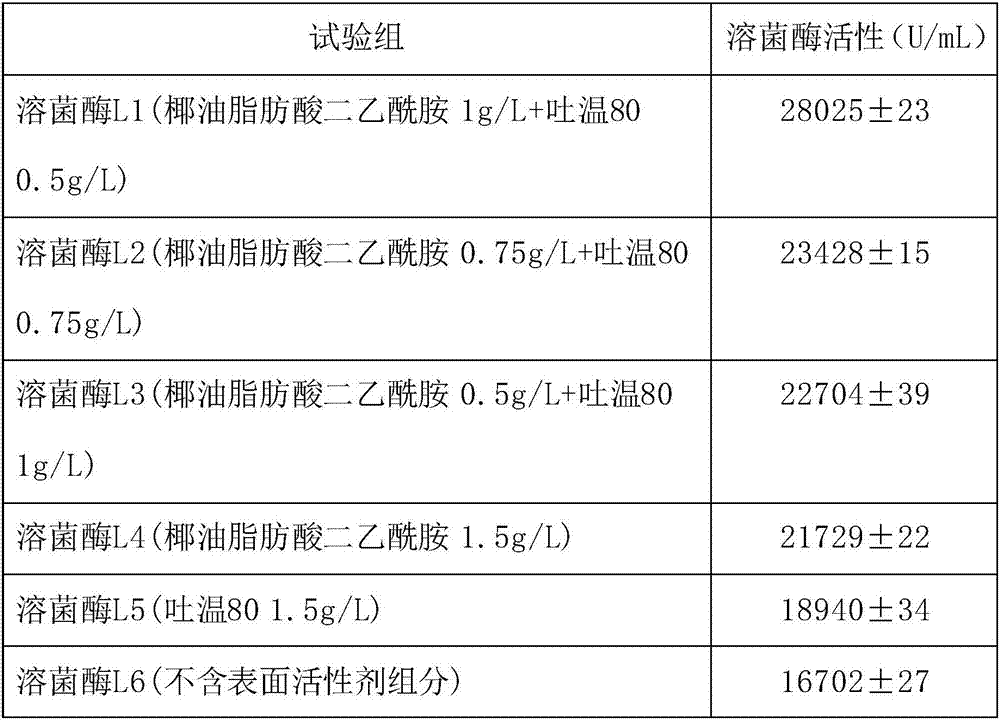

[0023] Prepare liquid culture medium, wherein glucose 10g / L, peptone 5g / L, coconut oil fatty acid diethylamide 1g / L, Tween 80 0.5g / L. Get 25mL liquid culture medium and place in Erlenmeyer flask, insert the thalline seed of Bacillus subtilis K-77 by 4% (v / v) inoculum amount, carry out shaking flask fermentation, fermentation condition is 30 ℃, 200r / min, After 24 hours of fermentation and cultivation, lysozyme L1 was obtained.

Embodiment 2

[0025] Prepare liquid culture medium, wherein glucose 10g / L, peptone 5g / L, coconut oil fatty acid diethylamide 0.75g / L, Tween 80 0.75g / L. Get 25mL liquid culture medium and place in Erlenmeyer flask, insert the thalline seed of Bacillus subtilis K-77 by 4% (v / v) inoculum amount, carry out shaking flask fermentation, fermentation condition is 30 ℃, 200r / min, After 24 hours of fermentation and cultivation, lysozyme L2 was obtained.

Embodiment 3

[0027] Prepare liquid culture medium, wherein glucose 10g / L, peptone 5g / L, coconut oil fatty acid diethylamide 0.5g / L, Tween 80 1g / L. Get 25mL liquid culture medium and place in Erlenmeyer flask, insert the thalline seed of Bacillus subtilis K-77 by 4% (v / v) inoculum amount, carry out shaking flask fermentation, fermentation condition is 30 ℃, 200r / min, After 24 hours of fermentation and cultivation, lysozyme L3 was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com