Preparation method of transfer diffusion film

A technology of diffusion film and transfer printing, which is applied in the field of diffusion film to achieve the effect of improving product yield, low cost and good haze

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

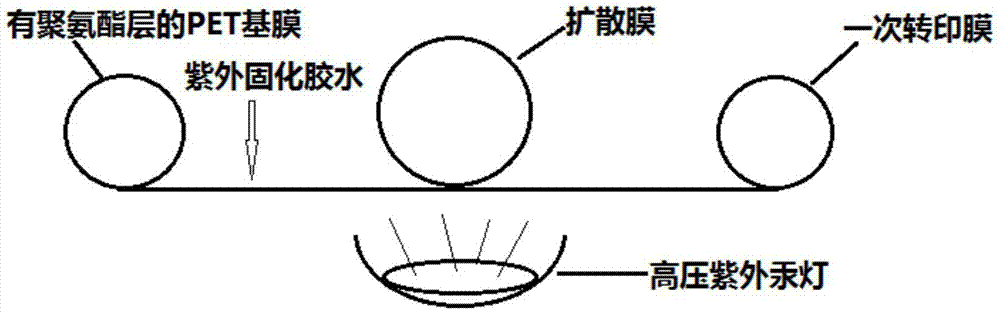

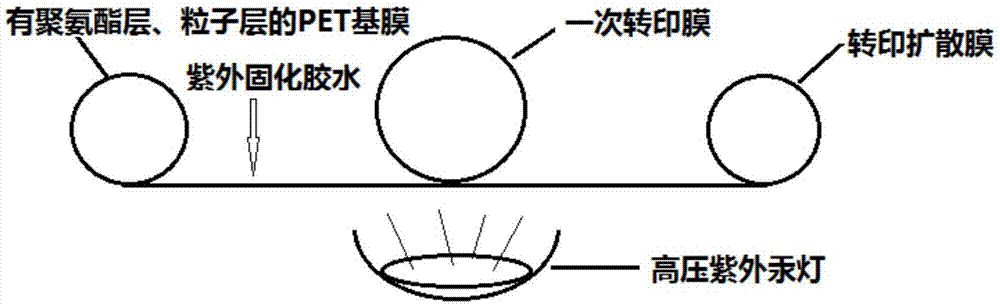

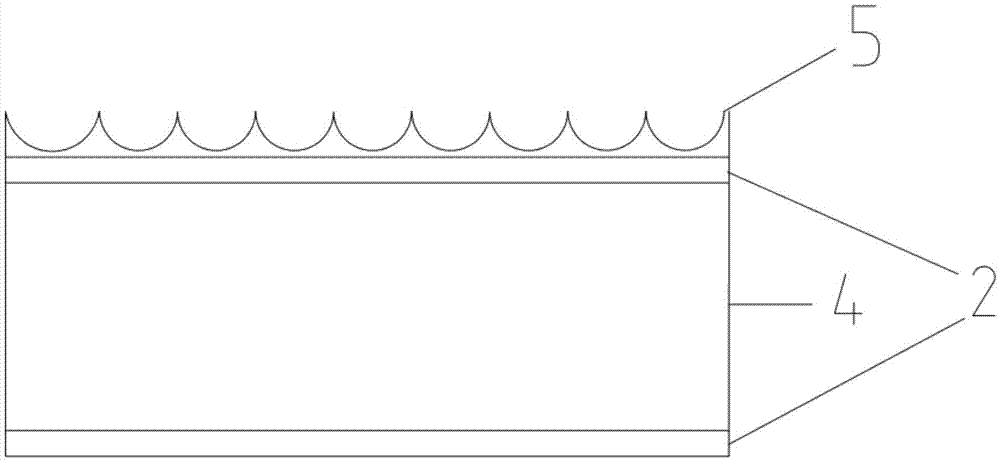

[0058] Such as figure 1 , figure 2 and image 3 Shown, the present invention also provides the preparation method of above-mentioned transfer diffusion membrane, described method comprises the following steps:

[0059] (1) Prepare the transfer template: coat the polyurethane layer 2 on the surface of the substrate layer 4, coat the solvent-free UV-curable resin glue on the surface of the polyurethane layer 2, paste the diffusion film and after UV irradiation, peel off the diffusion film , the solvent-free UV-curable resin glue forms a concave structure 5 to obtain a transfer template (also called a primary transfer film);

[0060] (2) Get the substrate layer made by three-layer co-extrusion of the extruder, coat the first polyurethane layer and the second polyurethane layer on the two surfaces of the substrate layer respectively; coat a polyurethane layer on the surface of the second polyurethane layer Layer anti-adhesion layer, drying; Coating solvent-free UV-curable resi...

Embodiment 1

[0063] The invention provides a transfer diffusion film. The preparation method is as follows:

[0064] (1) Preparation of transfer template: Take 100 parts of polyurethane coating liquid, 0.03 parts of polydimethylsiloxane leveling agent, 0.05 parts of SPA-202 defoamer, 200 parts of pure water, and mix them evenly with a stirrer Apply it on the PET base film, place it in an oven and heat and dry at 130°C for 5 minutes to form a polyurethane layer; then take solvent-based polyester glue, curing agent, solvent MEK, and PMMA organic particles, and mix them evenly under a stirrer according to a certain ratio, and coat Put it on the lower surface of the PET base film with the polyurethane layer, and dry it in an oven at 120°C for 1 min to form an anti-blocking layer. Apply a solvent-free acrylic glue with a refractive index of 1.45 on the upper surface of the polyurethane layer without an anti-adhesion layer, attach a diffusion film with an average height of particle protrusions ...

Embodiment 2

[0067] For the transfer diffusion film provided in Example 1, wherein the transfer diffusion layer uses solvent-free acrylic glue with a refractive index of 1.47, and after UV irradiation, the transfer template is peeled off to obtain a transfer diffusion film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Average height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com