Method for washing lead anode mud and recovering lead in lead anode mud

A lead anode slime and pickling technology, which is applied in the field of washing lead anode slime and recovering lead in lead anode slime, can solve problems such as non-leaching, lead recovery process research, etc., and achieve effective recovery, short purification time, and rapid treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

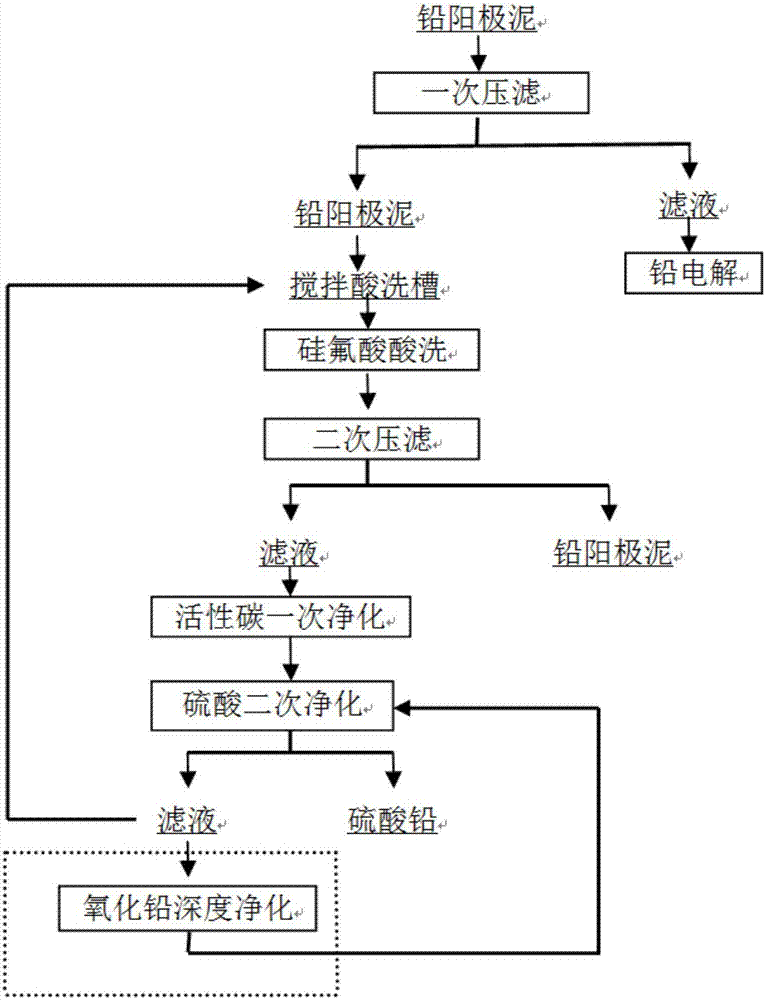

[0035] Such as figure 1 As shown, according to the method of washing lead anode slime of the present invention and reclaiming lead in lead anode slime, the lead anode slime with a weight percentage of lead of 30% is a raw material, mainly comprising the following steps:

[0036] (1) pressure filtration for the first time, after pressure filtration, the massfraction of the water in the control lead anode slime is 29%, will send the filtrate of gained after pressure filtration for the first time to electrolysis process and carry out direct recovery, will first time The lead anode slime obtained after press filtration contains 30% lead, and is sent to the stirring pickling tank for subsequent treatment;

[0037] (2) Agitate and pickle, add the fluosilicate solution with a concentration of 235g / L into the pickling tank, and the liquid-solid ratio of the mixture of the lead anode slime and the fluosilicate solution obtained after the first pressure filtration is 18:1 , stirring an...

Embodiment 2

[0046] Such as figure 1 As shown, according to the method for washing lead anode slime of the present invention and reclaiming lead in lead anode slime, the lead anode slime with a weight percentage of lead of 22.5% is a raw material, mainly comprising the following steps:

[0047] (1) pressure filtration for the first time, after pressure filtration, the massfraction of the water in the control lead anode slime is 27%, will send the filtrate of gained after pressure filtration for the first time to the electrolysis process and directly reclaim, the first time The lead anode slime obtained after press filtration contains 22.5% lead, and is sent to the stirring pickling tank for subsequent treatment;

[0048] (2) Add the fluorosilicic acid solution with a concentration of 145g / L into the pickling tank, and the liquid-solid ratio of the mixture of the lead anode slime and the fluorosilicic acid solution obtained after the first pressure filtration is 12:1, and pickling with stir...

Embodiment 3

[0057] Such as figure 1 As shown, according to the method for washing lead anode slime of the present invention and reclaiming lead in lead anode slime, the lead anode slime with a weight percentage of lead of 15% is a raw material, mainly comprising the following steps:

[0058] (1) pressure filtration for the first time, after pressure filtration, the massfraction of the water in the control lead anode slime is 25%, will send the filtrate of gained after pressure filtration for the first time to electrolysis process and carry out direct recovery, will first time The lead anode slime obtained after press filtration contains 15% lead, and is sent to the stirring pickling tank for subsequent treatment;

[0059] (2) Add the fluorosilicic acid solution with a concentration of 50g / L into the pickling tank, and the liquid-solid ratio of the mixture of the lead anode slime and the fluorosilicic acid solution obtained after the first pressure filtration is 6:1, and pickling with stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com