Preparation method and application of sterilization material employing loofah sponge as matrix

A technology of loofah and matrix, applied in the direction of botanical equipment and methods, separation methods, chemical instruments and methods, etc., can solve the problems of limited, unstable nano-silver, easy agglomeration and adsorption of nano-silver, and achieve easy use and preparation The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

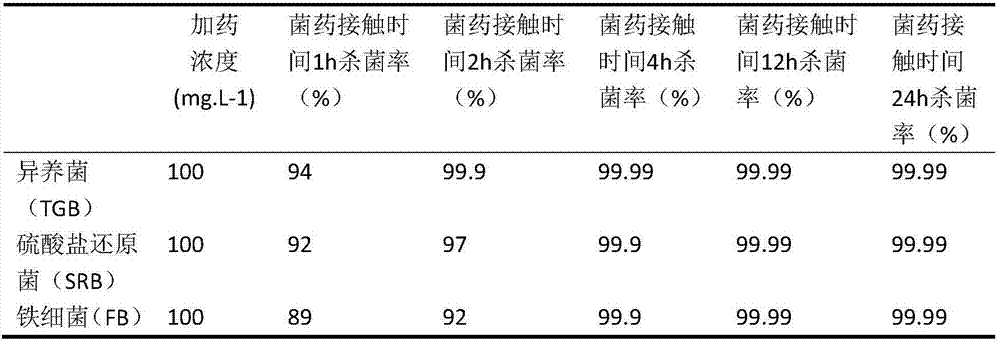

Examples

Embodiment 1

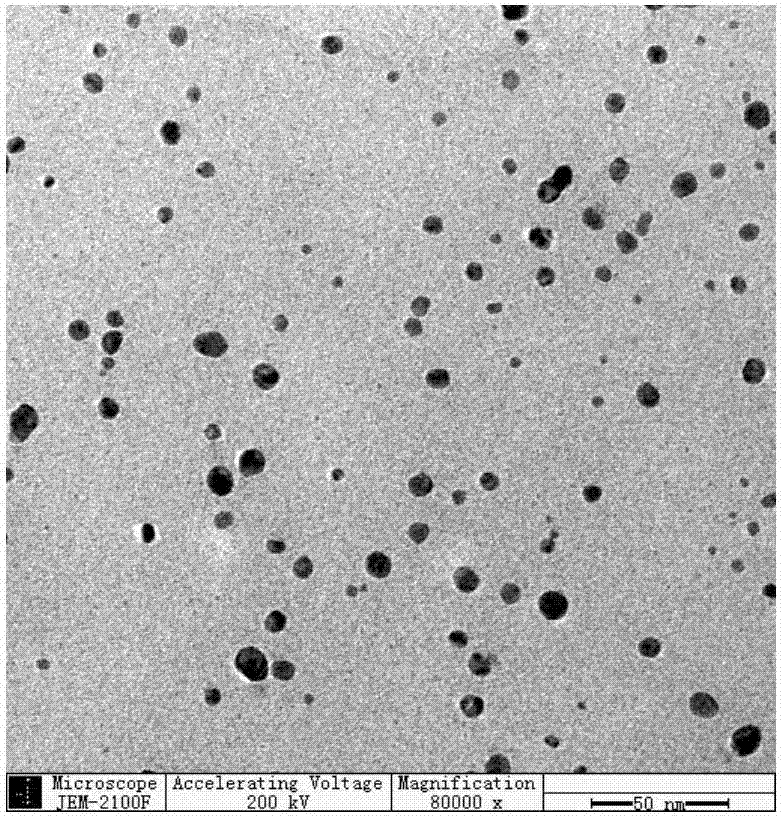

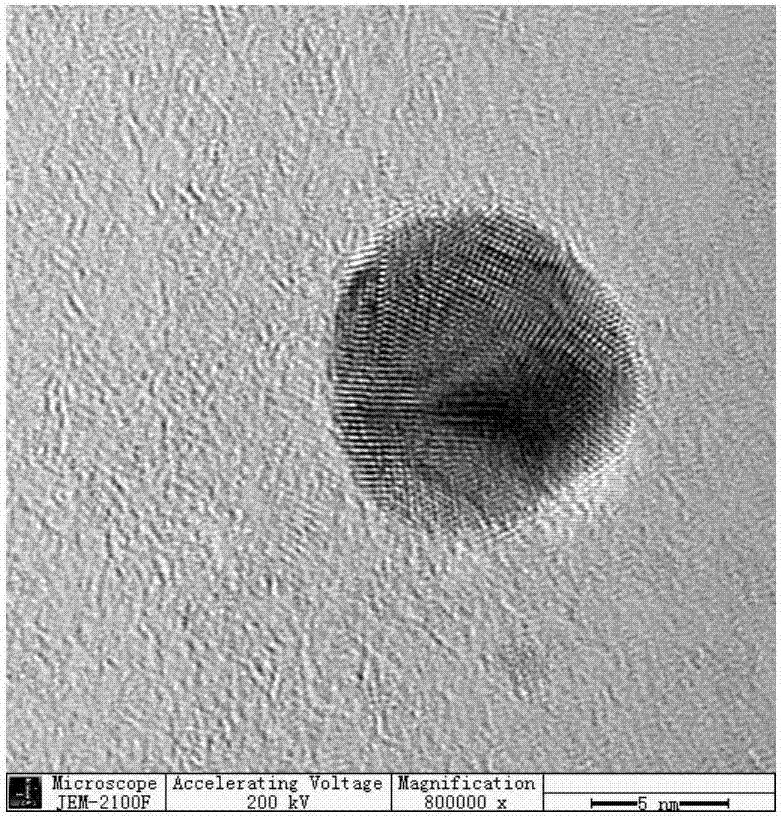

[0017] Embodiment 1 Preparation of bactericidal material with loofah as matrix

[0018] Pre-preparation of nano-silver sol: Take a 100mL small beaker, add 100ml deionized water, add 0.6g chitosan into deionized water under stirring, add 0.2ml glacial acetic acid to help dissolve, and hydrolyze at room temperature for 6 hours. Take a 250mL three-neck bottle, add a magnet, insert a condenser tube, and a sodium hydroxide drying tube is installed on the condenser tube, add the above-mentioned dissolved chitosan solution, and heat in a water bath to 60°C. Dissolve 0.10g of silver nitrate in 50ml of deionized water to obtain a silver nitrate solution, and slowly add the prepared silver nitrate solution to the system dropwise. After the dropwise addition, raise the temperature to 80°C and react at a constant temperature for 12 hours to obtain a golden yellow nano-silver colloidal solution. spare. Ripe loofah fruit is peeled and pitted, washed and dried to obtain unmodified loofah. ...

Embodiment 2

[0019] Embodiment 2 Preparation of bactericidal material with loofah as matrix

[0020] The preparation conditions are basically the same as in Example 1, except that the following changes exist in the preparation conditions: instead of soaking the loofah in the nano-silver solution, the nano-silver sol is attached to the loofah by spraying. Other conditions are the same as Example 1.

Embodiment 3

[0021] Example 3 Preparation of bactericidal material based on loofah

[0022] The preparation conditions are basically the same as Example 1, and there are the following changes in the preparation conditions: the original ultrasonic condition of soaking the loofah in the nano-silver solution is changed to natural soaking in the dark for 6 hours, then it is taken out and controlled to dry, and then put into a 120 degree oven for drying . Other conditions are the same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com