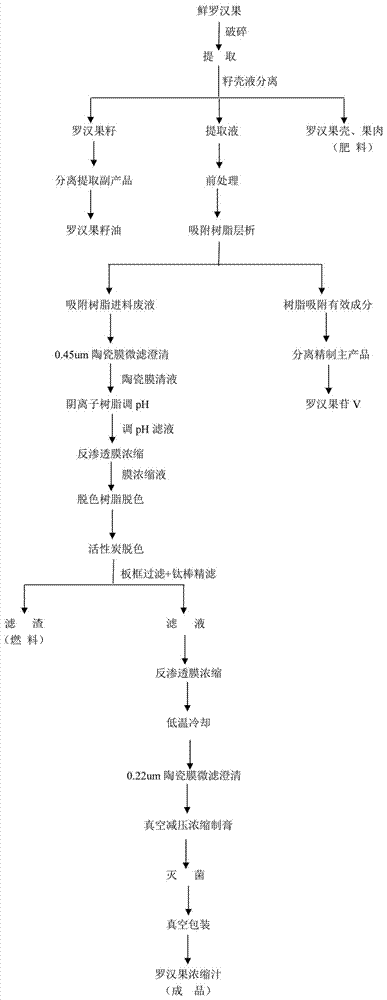

Production technology of fructus momordicae concentrated juice by waste liquid discharged from adsorbent resin columns of momordica glycosides

A technology of concentrated monk fruit juice and adsorption resin column, which is applied in the fields of food adsorption, medical preparations containing active ingredients, food science, etc., can solve the problems of meeting the standard of direct drainage, difference in treatment degree, and pollution of the environment by producing monk fruit, and saves money. The effect of concentrating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] 1) 0.45um ceramic membrane microfiltration clarification

[0056] Take 25,000 kg of waste liquid from the adsorption resin in the production process of fresh Luo Han Guo, and pump it into the upstream tank of the ceramic membrane. The pore size of the ceramic membrane is 0.45um. Start the operation of the complete set of ceramic membrane equipment to remove water-insoluble impurities and turbid substances to obtain ceramic membrane clear liquid.

[0057] 2) Anion resin to adjust pH

[0058] Pump the ceramic membrane liquid into the high-level chromatography tank, control the feed rate of the high-level tank and the output of the chromatography column to 1.5BV / h, and adjust the outflow by filling an anion exchange resin column with a quantity of 1200kg and a model of D201×7 The pH range of the solution was 5.9, and the pH filtrate was adjusted.

[0059] 3) Reverse osmosis membrane concentration

[0060] Pump the pH-adjusted filtrate into the upstream tank of the rever...

Embodiment 2

[0083] 1) 0.45um ceramic membrane microfiltration clarification

[0084] Take 10,000 kg of waste feed liquid of adsorption resin in the production process of fresh Luo Han Guo, and pump it into the upstream tank of the ceramic membrane. The pore size of the ceramic membrane is 0.45um. Start the operation of the complete set of ceramic membrane equipment to remove water-insoluble impurities and turbid substances to obtain ceramic membrane clear liquid.

[0085] 2) Anion resin to adjust pH

[0086] Pump the ceramic membrane clear liquid into the high-level chromatography tank, control the feed rate of the high-level tank and the output flow rate of the chromatography column to 1.6BV / h, and adjust the flow rate of the effluent by filling an anion exchange resin column with a quantity of 470kg and a model of D315. The pH range was 6.1, and the pH-adjusted filtrate was obtained.

[0087] 3) Reverse osmosis membrane concentration

[0088] Pump the pH-adjusted filtrate into the up...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com