Decrosslinking foamed EVA modified asphalt and preparation method thereof

A technology for modifying asphalt and de-crosslinking, applied in building components, building thermal insulation materials, buildings, etc., can solve the problems of inability to use asphalt modifiers, difficult to pulverize into fine particles, and inability to uniformly disperse asphalt, and to improve Water damage resistance, improve the efficiency of de-crosslinking, and solve the effect of difficult recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A kind of decrosslinking foaming EVA modifier is prepared by the following method:

[0025] (1) According to the mass percentages of each raw material: foaming EVA80%, steel slag powder 20%, choose foaming EVA and steel slag powder, mix evenly;

[0026] (2) Add the above-mentioned cross-linked foaming EVA and steel slag powder mixture into the internal mixer for mechanochemical de-crosslinking. The temperature of the internal mixer is set at 170°C, the speed is set at 30r / min, and the time for de-crosslinking is 20min;

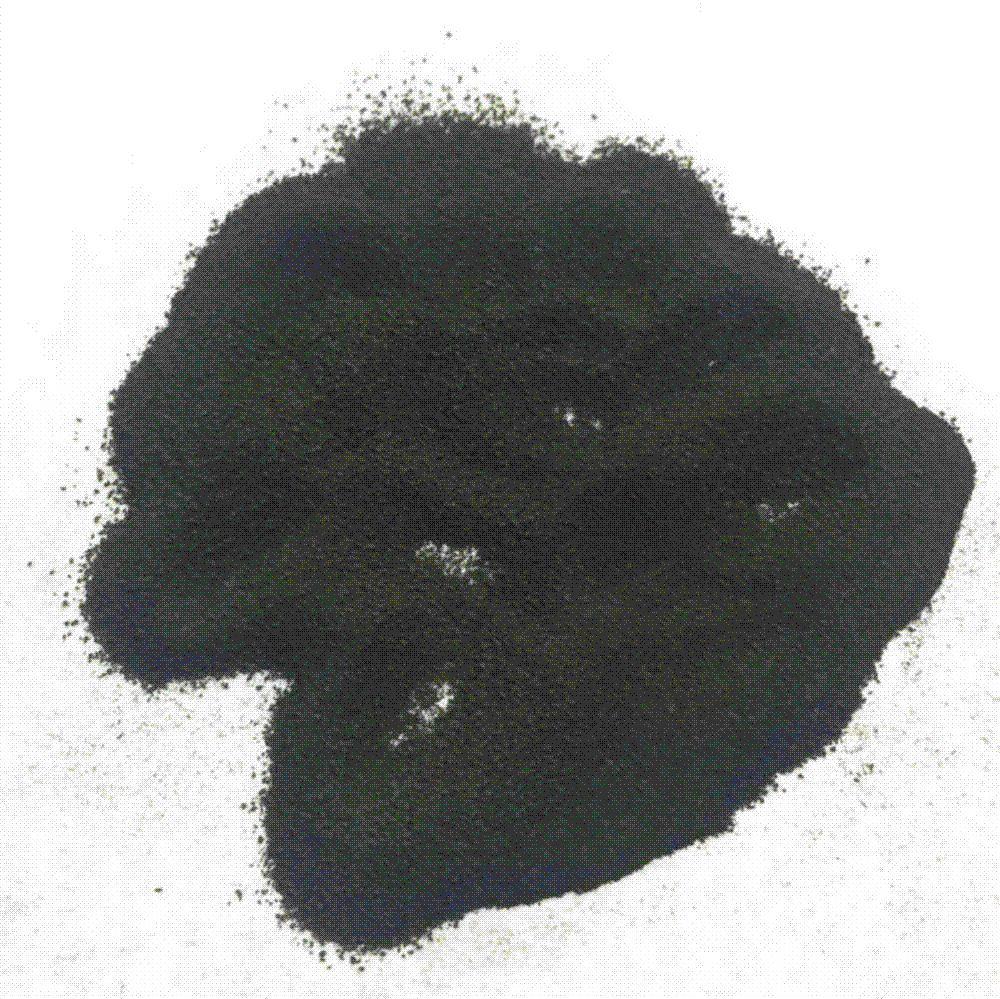

[0027] (3) the above-mentioned foaming EVA and steel slag powder blend through mechanochemical decrosslinking are placed in a pulverizer, pulverized and sieved to obtain a decrosslinked EVA modifier (such as figure 1 shown).

Embodiment 2

[0029] A kind of decrosslinking foaming EVA modifier is prepared by the following method:

[0030] (1) According to the mass percentages of each raw material: foaming EVA90%, steel slag powder 10%, choose foaming EVA and steel slag powder, mix evenly;

[0031] (2) Add the above-mentioned cross-linked foaming EVA and steel slag powder mixture into the internal mixer for mechanochemical de-crosslinking. The temperature of the internal mixer is set at 170°C, the speed is set at 30r / min, and the time for de-crosslinking is 25min;

[0032] (3) the above-mentioned foaming EVA and steel slag powder blend through mechanochemical decrosslinking are placed in a pulverizer, pulverized and sieved to obtain a decrosslinked EVA modifier (such as figure 1 shown).

Embodiment 3

[0034] Heat 91.5 parts of road petroleum asphalt (penetration of 73dmm at 25°C, softening point of 48.2°C, ductility at 5°C of 0.6cm) to 180°C, and add 8.5 parts of decrosslinked foaming EVA prepared in Example 1 Modifier, after all the modifiers are added, keep the temperature at 175°C±5°C, start the high-speed shearing machine, and stir at 5000rpm for 60min to obtain decrosslinked EVA modified asphalt. After testing, the softening point of decrosslinked EVA modified asphalt is 69.7°C, the penetration at 25°C is 44dmm, and the ductility at 5°C is 7.6cm. Compared with the base asphalt, the high-temperature performance (softening point) and low-temperature performance (5°C ductility) of the decrosslinked EVA modification were significantly improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com