Heat-conductive radiating coating

A heat-dissipating coating and heat-dissipating material technology, which is applied in the direction of epoxy resin coating, polyurea/polyurethane coating, coating, etc., can solve the problems of increasing equipment volume, equipment performance degradation, and burning out equipment, so as to improve heat dissipation efficiency and use Convenience and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Preparation materials: MDI5011.88g, long-chain saturated polyether diol A120g, organotin 0.673g, toluene: 31.88g.

[0021] Take 120g of long-chain saturated polyether diol A, 31.88g of toluene and 0.673g of organotin, heat up to 70°C in a nitrogen atmosphere, slowly add MDI5011.88g in a constant pressure funnel, start timing after adding MDI50, and react for 3 hours The reaction was stopped to obtain a hydroxyl-terminated PU protoplasm with a molecular weight of about 15,000. Dilute the PU puree to a solid content of 5%-50%, add nano-modified mica powder, ALN powder, BN powder, SiO2 powder, nano-modified graphite and additives to disperse in a high-speed disperser to obtain a stable solid content 40% black heat-conducting heat-dissipating paint. The auxiliary agent is one of thixotropic agent, antiaging agent, defoamer, dispersant, coupling agent, tackifier or a mixture thereof. It is necessary to add an appropriate amount of curing agent when coating. Wherein the cu...

Embodiment 2

[0024] Preparation materials: HDI1001.584g, long-chain saturated polyether diol A240g, organotin 0.673g, cyclohexane: 27.72g.

[0025] Take 220g of long-chain saturated polyether diol A, 27.72g of cyclohexane and 0.673g of organotin, raise the temperature to 70°C in a nitrogen atmosphere, slowly add HDI1001.584g in a constant pressure funnel, and start timing after adding HDI100, the reaction After 3 hours, the reaction was stopped to obtain a hydroxyl-terminated PU puree with a molecular weight of about 50,000. Dilute the PU puree to a solid content of 5%-50%, add nano-modified mica powder, ALN powder, BN powder, SiO2 powder, nano-modified graphite and additives to disperse in a high-speed disperser to obtain a stable solid content About 35% black heat dissipation paint. It is necessary to add an appropriate amount of curing agent when coating. Wherein the curing agent can be isocyanate and amine curing agent.

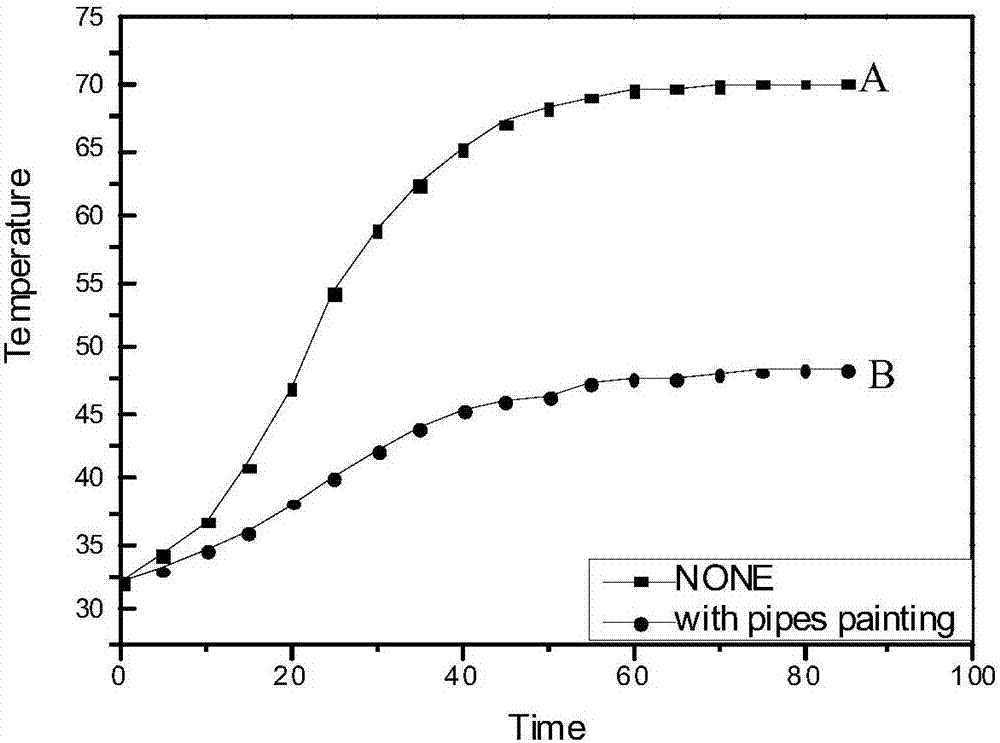

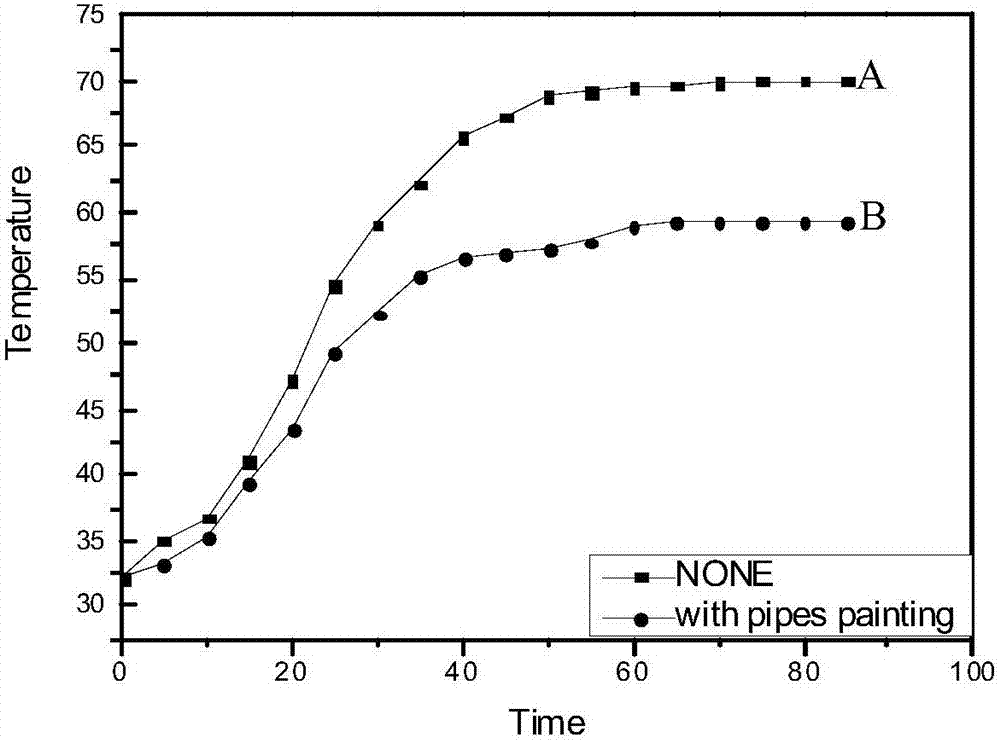

[0026] Apply this heat-conducting and heat-dissipating coatin...

Embodiment 3

[0028] Preparation materials: MDI1009.75g, long-chain saturated polyether triol A340g, organic bismuth 0.673g, ethyl acetate: 12.44g

[0029] Take 340g of long-chain saturated polyether triol A, 12.44g of ethyl acetate and 0.673g of organic bismuth, raise the temperature to 70°C in a nitrogen atmosphere, slowly add MDI1009.75g into the constant pressure funnel, and start timing after adding HDI100, the reaction After 3 hours, the reaction was stopped to obtain a hydroxyl-terminated PU puree with a molecular weight of about 50,000. Dilute the PU puree to a solid content of 5%-50%, add about 10% epoxy resin, nano-modified mica powder, ALN powder, BN powder, SiO2 powder, nano-modified graphite and additives in a high-speed disperser Disperse to obtain a stable black heat-conducting and heat-dissipating coating with a solid content of about 35%. It is necessary to add an appropriate amount of curing agent when coating. Wherein the curing agent can be isocyanate and amine curing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com