Special chelating agent for oil-gas field fracturing

A chelating agent, oil and gas field technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problem of scale damage to formations, and achieve the effects of reducing safety hazards, protecting formations, and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

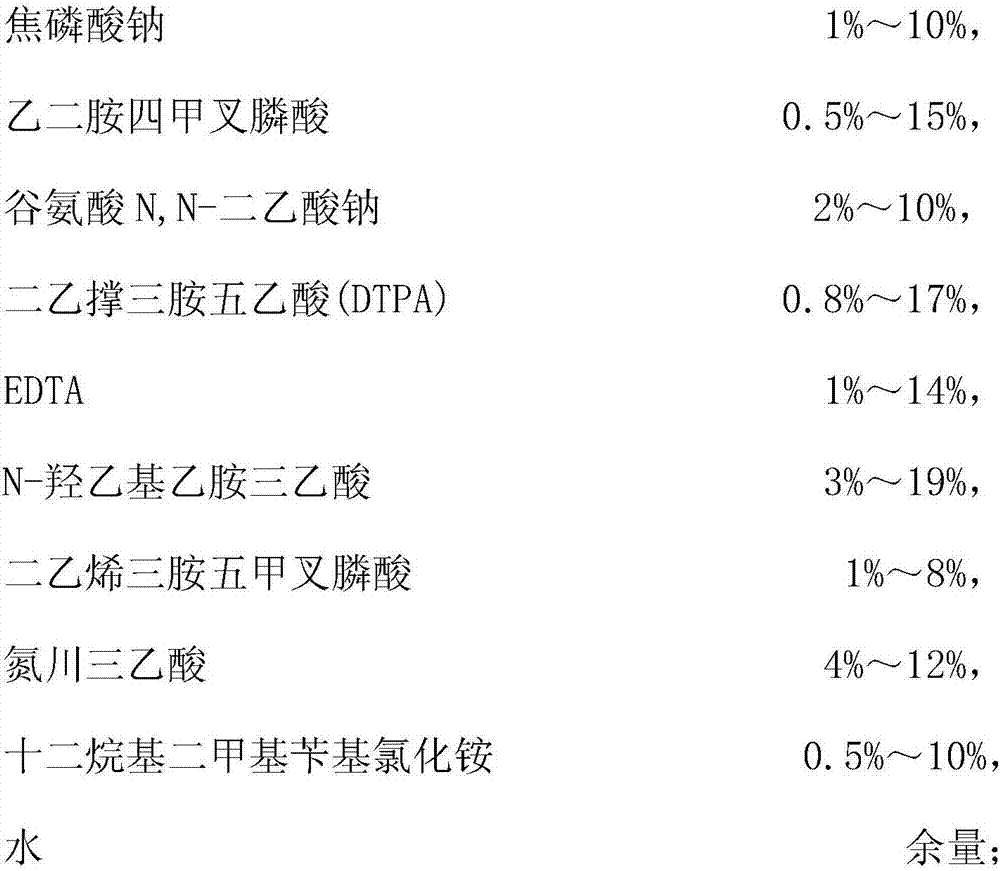

Method used

Image

Examples

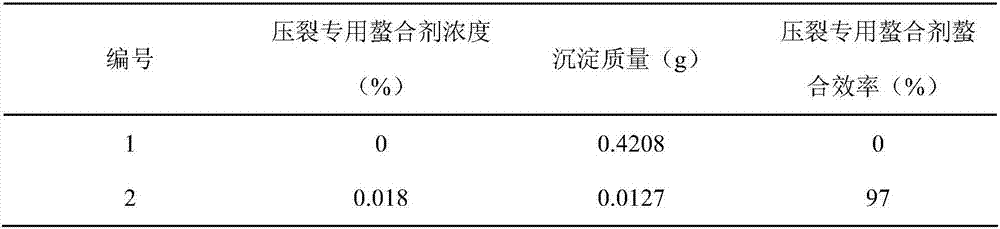

Embodiment 1

[0013] (1), get 5% sodium pyrophosphate, 8% ethylenediaminetetramethylenephosphonic acid, 8% glutamic acid N,N-sodium diacetate, 13% diethylenetriacetate by mass percentage Amine pentaacetic acid (DTPA), 11% EDTA, 17% N-hydroxyethylethylamine triacetic acid, 3% diethylene triamine pentamethylidene phosphonic acid, 6% nitrilotriacetic acid, 5% ten Dialkyldimethylbenzylammonium chloride and 29% water are fully mixed and uniform to prepare a finished product of a special chelating agent for oil and gas field fracturing.

[0014] (2) Mix 200ml of fracturing water and simulated formation water to prepare a guar gum solution with a mass concentration of 0.45%, and then add 0.50% foaming agent (HK309), 0.50% drainage aid (HK101), 0.50% % clay stabilizer (HK104), 0.10% bactericide (HK103) and 0.12% soda ash to make base liquid.

[0015] (3) Divide the base fluid obtained in step (2) into two parts, each part is 200ml, one part is added with a fracturing special chelating agent with a...

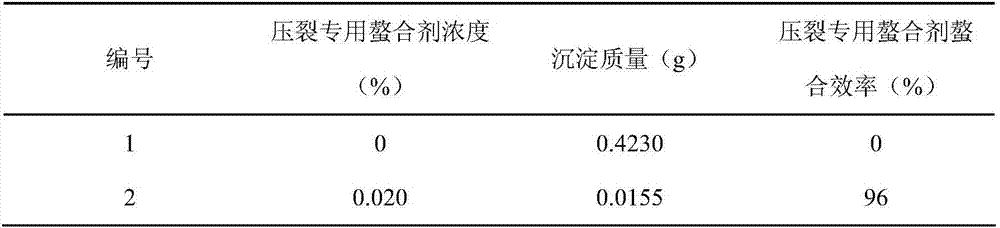

Embodiment 2

[0020] (1), get 4% sodium pyrophosphate, 6% ethylenediaminetetramethylenephosphonic acid, 9% glutamic acid N,N-sodium diacetate, 11% diethylenetriacetate by mass percentage Amine pentaacetic acid (DTPA), 10% EDTA, 15% N-hydroxyethylethylamine triacetic acid, 3% diethylene triamine pentamethylidene phosphonic acid, 5% nitrilotriacetic acid, 4% ten Dialkyldimethylbenzylammonium chloride and 33% water are fully mixed and uniform to prepare a finished product of a special chelating agent for oil and gas field fracturing.

[0021] (2) Mix 200ml of fracturing water and simulated formation water to prepare a guar gum solution with a mass concentration of 0.45%, and then add 0.50% foaming agent (HK309), 0.50% drainage aid (HK101), 0.50% Clay stabilizer (HK104), 0.10% bactericide (HK103) and 0.12% soda ash were prepared as base liquid.

[0022] (3) Divide the base fluid obtained in step (2) into two parts, each part is 200ml, and one part is added with a special chelating agent for fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com