Folded film capacitor and manufacturing method thereof

A technology of film capacitors and manufacturing methods, which is applied in the direction of film/thick film capacitors, laminated capacitors, fixed capacitor leads, etc., can solve the problem that the small contact area cannot effectively improve the contact resistance of the electrode end, which is easy to fall off, and the energy storage density of the capacitor Problems such as drop and increase of non-stacked parts can solve the problems of less contact points, reduce current density and loss, and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific technical solutions of the present invention will be further described below in conjunction with the accompanying drawings.

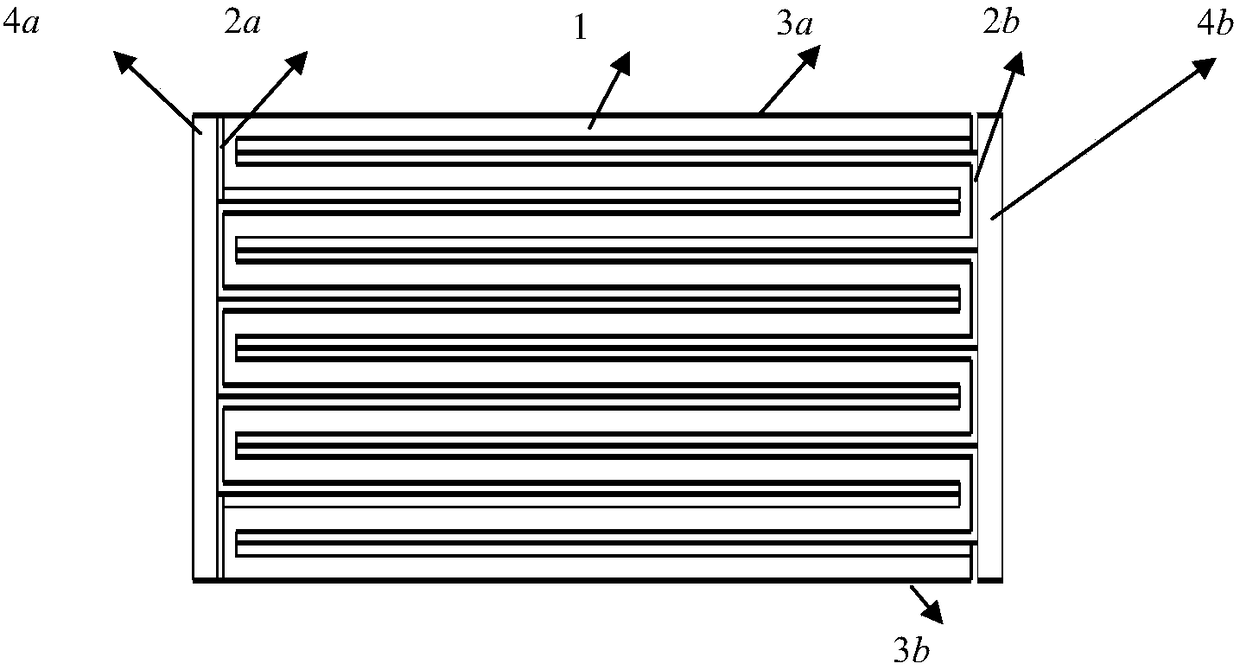

[0029] Such as Figure 3-4 As shown, a folded film capacitor of the present invention, the film capacitor has a laminated body formed by folding multiple metallized films, and the organic film and metal vapor-deposited film of the metallized film are stacked alternately. It should be noted that, The number of folded layers of the metallized film in the film folded film capacitor of the present invention is not limited by the accompanying drawings.

[0030] By folding the two sides of the film capacitor, there is a metal vapor-deposited film on the entire surface, and by spraying metal particles on the metal vapor-deposited film on the side to form the gold-sprayed layers 4a and 4b, the gold-sprayed layer can be reliably bonded to the metal vapor-deposited film on the side. The coatings are joined together. The constituent materials...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com