High-power high-current ion source four-electrode support base component

An ion source and four-electrode technology, applied in electrical components, ion beam tubes, circuits, etc., can solve the problems of high cost and high dynamic pumping speed requirements of the pumping system, reduce the processing accuracy requirements, increase the area of the pumping port, Ensuring uniform and consistent results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

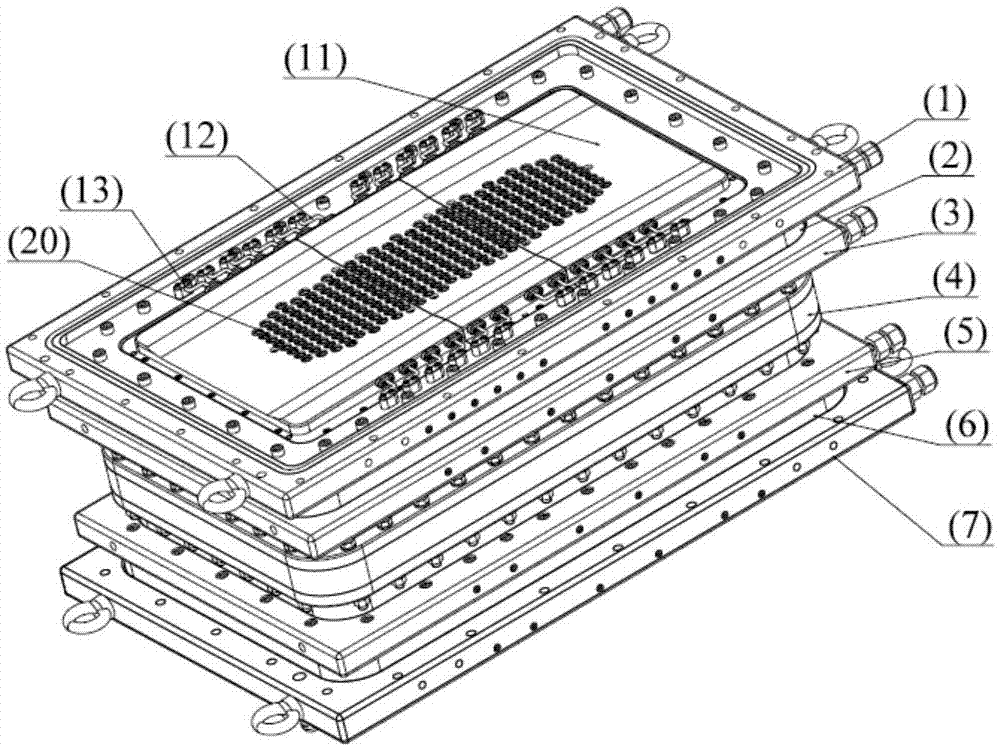

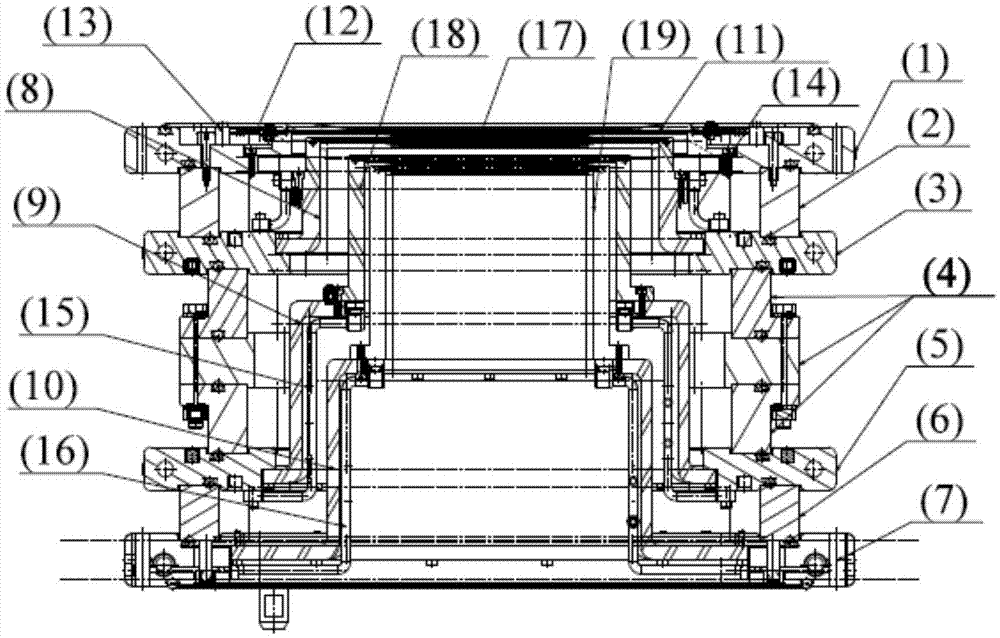

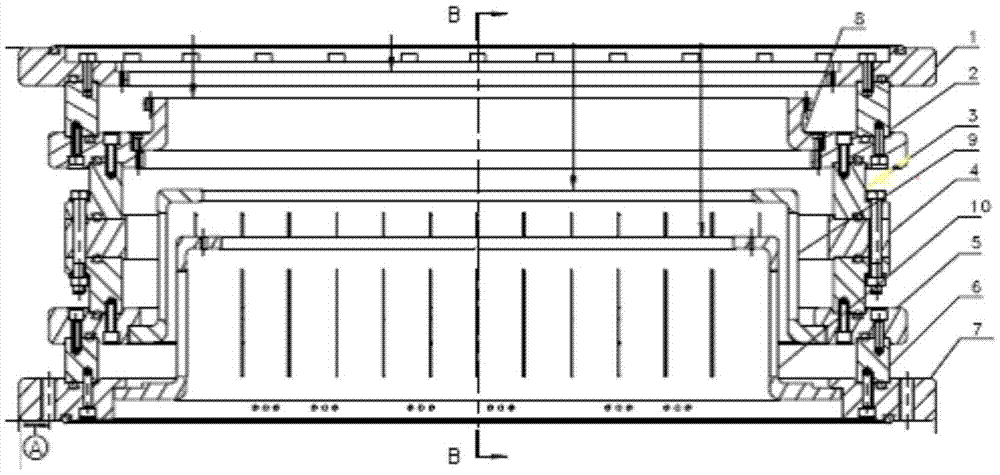

[0028] Taking the 80kV, 45A, 5s ion source electrode support assembly as an example, the specific implementation is given. The ion source electrode support assembly such as image 3As shown, the overall dimensions are 780mm in length, 506mm in width, and 318mm in height. It mainly consists of the first flange 1, the first insulating cavity 2, the second flange 3, the second insulating cavity 4, the third flange 5, the third insulating cavity 6, the fourth flange 7, the second electrode bracket 8, The third electrode support 9, the fourth electrode support 10 and other components are composed.

[0029] The first flange 1 is used to support the first electrode grid 11 and provide access for the water cooling circuit of the first electrode grid 11 . It cooperates with the first insulating chamber 2, the first electrode grid 11 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com