Method for reducing high-temperature storage gas production of high-nickel batteries

A battery and high-temperature technology, applied in electrical components, battery electrodes, secondary batteries, etc., can solve the problems of battery high-temperature storage and gas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

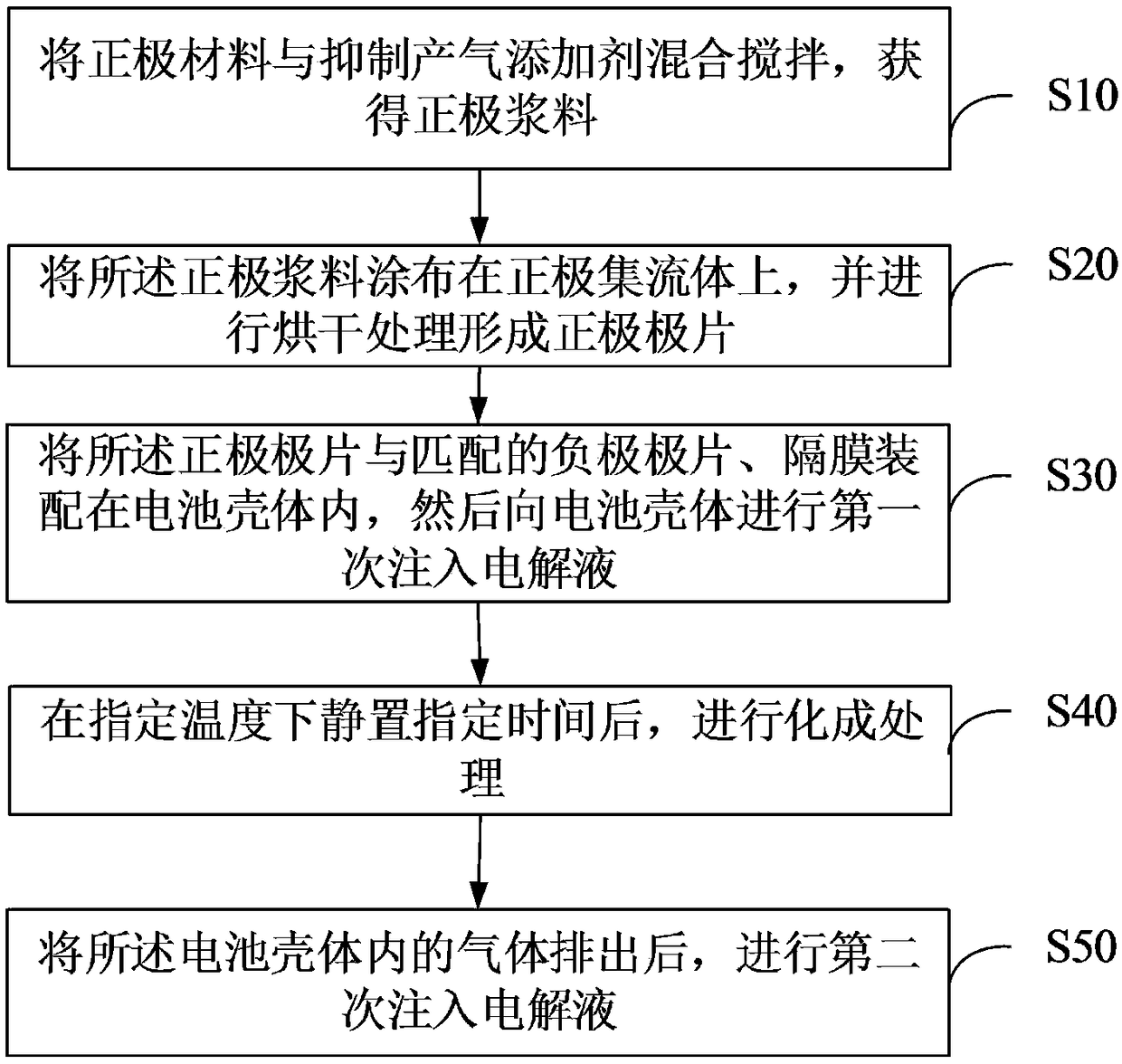

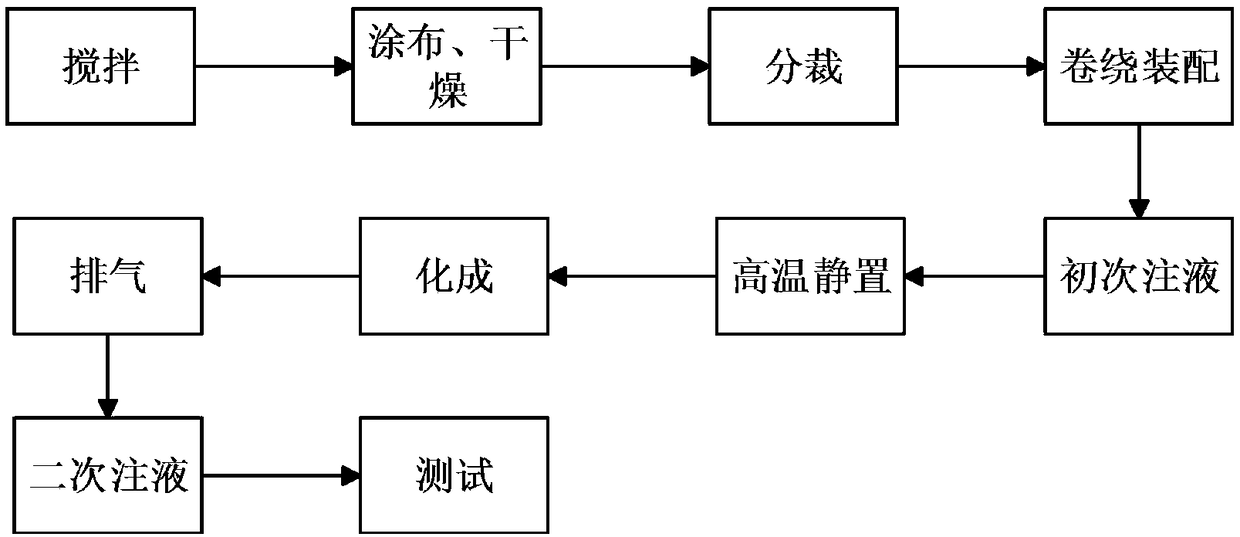

Method used

Image

Examples

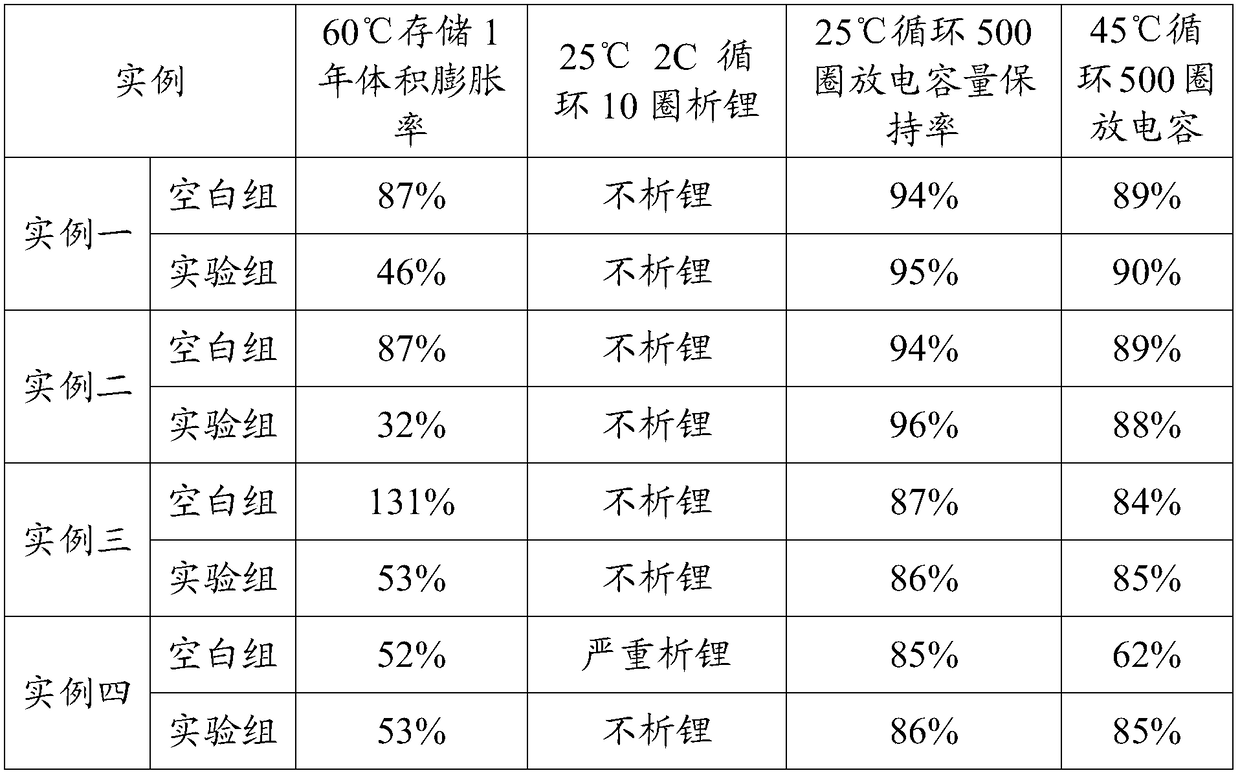

example 1

[0060] The positive electrode material is NCM523. During stirring, the experimental group added 0.5% PS of the positive electrode material mass, and made a 2Ah soft pack battery according to the above process, and its working voltage was 2.8-4.4V. Here, the quality of the positive electrode material only refers to the quality of the ternary active material, not including other additives that need to be added to the positive electrode. The blank group did not add additives, and was treated according to the conventional process.

example 2

[0062] The positive electrode material is NCM523. The experimental group added PST with a mass of 0.5% of the positive electrode material mass during stirring, and made a 2Ah soft pack battery according to the above process, and its working voltage was 2.8-4.4V. Here, the quality of the positive electrode material only refers to the quality of the ternary active material, not including other additives that need to be added to the positive electrode. The blank group did not add additives, and was treated according to the conventional process.

example 3

[0064] The positive electrode material is NCM622. During stirring, the experimental group added 0.5% PS of the positive electrode material mass, and made a 2Ah soft pack battery according to the above process, and its working voltage was 2.8-4.2V. Here, the quality of the positive electrode material only refers to the quality of the ternary active material, not including other additives that need to be added to the positive electrode. The blank group did not add additives, and was treated according to the conventional process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com