An application method of a device for producing high-concentration SO2 gas using magnesium desulfurization products

An application method, magnesium desulfurization technology, applied in the direction of separation methods, sulfur compounds, chemical instruments and methods, etc., can solve the problems of lack of high-grade limestone resources, waste of magnesium resources, low thermal decomposition rate, etc., to reduce the one-time investment , good economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

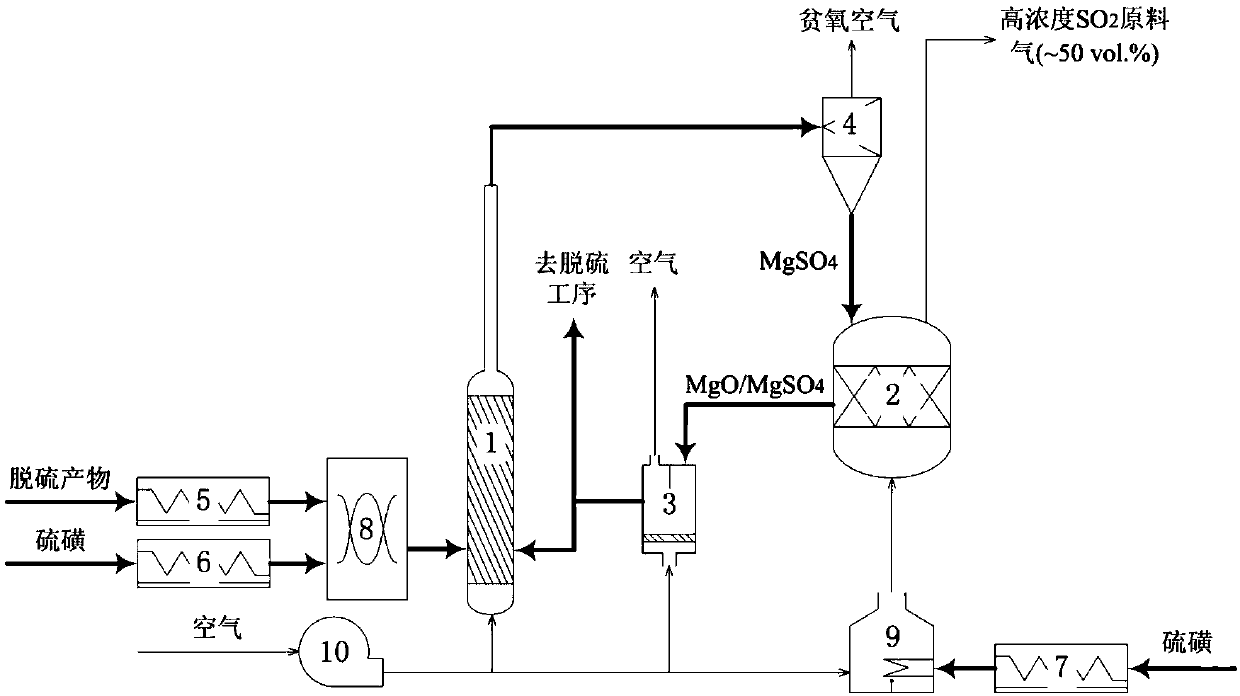

[0031] The invention provides a method for producing high-concentration SO by using magnesium desulfurization products 2 The application method of the gas device, its flow chart is as follows figure 1 shown. It includes oxidation sulfur fixer 1 , reduction regenerator 2 , feeder 3 , cyclone separator 4 , screw feeders 5 , 6 , 7 , agitator 8 , incinerator 9 and blower 10 . The feeder 3 is connected between the oxidation sulfur fixer 1 and the reduction regenerator 2, the top of the oxidation sulfur fixer 1 is connected to the upper part of the reduction regenerator 2 through the cyclone separator 4, and the lower part of the oxidation sulfur fixer 1 is equipped with The feed inlet for the mixture of flue gas desulfurization products and sulfur particles, the feed inlet for desulfurization agent particles return, and the air inlet. The lower part of the reduction regenerator 2 is provided with a mixed gas inlet port of sulfur vapor and air and a discharge port of desulfurizer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com