Preparation method of nutrient liquid prepared from black funguses, black rice and blueberry fruits

The technology of black fungus and black rice is applied in the field of preparation of black fungus, black rice and blueberry nutritious rice dew, and can solve the problems of no obvious progress in the utilization of black rice, affecting the edible value of black rice, and being difficult to boil the black rice. The effect of high value-added development and utilization, enhancing human immunity and protecting eyesight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

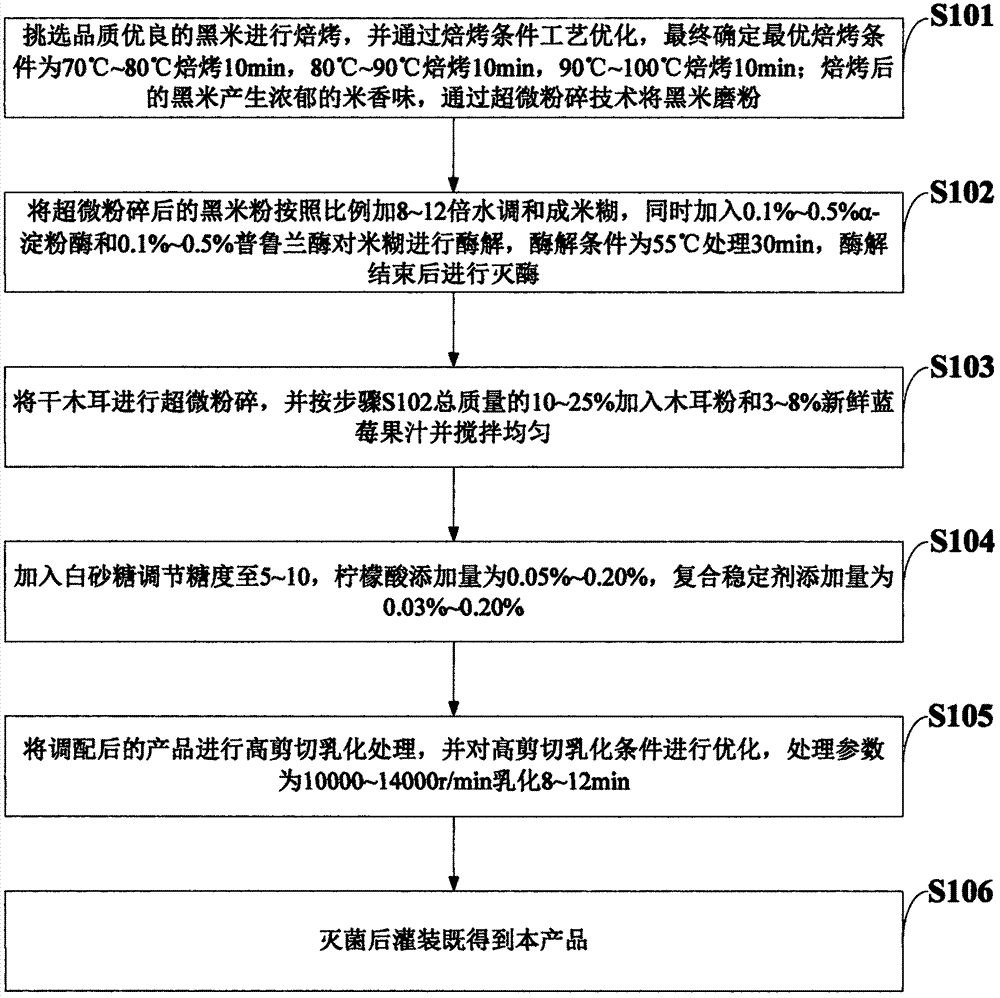

[0035] Such as figure 1 As shown, the preparation method of the black fungus, black rice and blueberry nutritional rice dew of the embodiment of the present invention comprises the following steps:

[0036] S101: Select high-quality black rice for roasting, and optimize the roasting conditions, and finally determine the optimal roasting conditions as 70°C-80°C for 10 minutes, 80°C-90°C for 10 minutes, and 90°C-100°C for 10 minutes; The final black rice produces a strong rice fragrance, and the black rice is ground into powder by ultra-fine grinding technology;

[0037] S102: Blend the ultrafinely pulverized black rice flour with 8-12 times of water in proportion to form rice paste, and at the same time add 0.1%-0.5% α-amylase and 0.1%-0.5% pullulanase to enzymatically hydrolyze the rice paste , the enzymolysis condition is 55°C for 30 minutes, and the enzyme is inactivated after the enzymolysis is completed;

[0038] S103: Superfinely pulverize the dried fungus, add fungus p...

Embodiment 1

[0044] (1) Select high-quality black rice for roasting, bake at 75°C for 10 minutes, bake at 85°C for 10 minutes, and bake at 95°C for 10 minutes; after roasting, the black rice will produce a strong rice fragrance, and the black rice will be ground into powder by ultrafine grinding technology;

[0045] (2) Add 10 times of water to the black rice powder after superfine pulverization according to the proportion to make rice paste, add 0.5% α-amylase and 0.5% pullulanase to enzymolyze the rice paste at the same time, the enzymolysis condition is 55 ℃ for 30 minutes, after the end of enzymolysis, 80 ℃ for 10 minutes to inactivate the enzyme;

[0046] (3) Superfinely pulverize the dried fungus, add fungus powder and 3% fresh blueberry juice according to 10% of the total mass of step (2), and stir evenly;

[0047] (4) adjust the sugar content to 8 with white granulated sugar; the addition of citric acid is 0.08%, and the addition of compound stabilizer is 0.1%;

[0048] (5) The prep...

Embodiment 2

[0051] (1) Select high-quality black rice for roasting, bake at 80°C for 10 minutes, bake at 90°C for 10 minutes, and bake at 100°C for 10 minutes. After roasting, the black rice will produce a strong rice fragrance, and the black rice will be ground into powder by ultrafine grinding technology;

[0052] (2) Add 10 times of water to the black rice powder after superfine pulverization according to the proportion to make rice paste, add 0.5% α-amylase and 0.5% pullulanase to enzymolyze the rice paste at the same time, the enzymolysis condition is 55 ℃ for 30 minutes, after the end of enzymolysis, 80 ℃ for 10 minutes to inactivate the enzyme;

[0053] (3) Superfinely pulverize the dried fungus, add fungus powder and 3% fresh blueberry juice according to 12% of the total mass of step (2) and stir evenly;

[0054] (4) adjust the sugar content to 8 with white granulated sugar; the added amount of citric acid is 0.10%, and the added amount of compound stabilizer is 0.150%;

[0055] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com