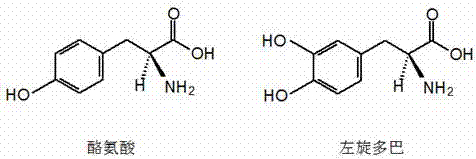

Method of simultaneously extracting high purity tyrosine and levodopa from seed of stizolobium cochinchinensis

A technology of levodopa and tyrosine, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problem of not involving active ingredients - tyrosine extraction and separation, complex process, high equipment requirements problems, to achieve the effect of low cost, strong operability, and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] (1) Grinding and enzymatic hydrolysis of raw materials: Grind 100kg of cat bean raw materials with a low-temperature pulverizer until the particle size is 80 mesh, then add 100kg of water, 1.5kg of protease preparation and 0.15kg of vitamin E, mix well, and enzymatically hydrolyze at 20°C 10h, get 201kg enzymatic hydrolyzate;

[0051] (2) Extraction and nanofiltration: Add 1100 kg of methanol aqueous solution with a volume concentration of 20% to the 201 kg of enzymatic hydrolyzate obtained in step (1), stir and extract at room temperature for 4 hours, filter, and use a nanofiltration membrane with a molecular weight cut-off of 1.0 kDa to Filter to get 1000kg permeate;

[0052] (3) Concentration and crystallization: Concentrate 1000kg of the permeate obtained in step (2) with a falling film concentrator until the total solids mass concentration is 15%, cool to room temperature, and adjust the pH value with 5% hydrochloric acid aqueous solution to 5.3, stirred and cryst...

Embodiment 2

[0056] (1) Grinding and enzymatic hydrolysis of raw materials: Grind 200kg of cat bean raw materials with a low-temperature pulverizer until the particle size is 100 mesh, then add 400kg of water, 8kg of protease preparation and 0.8kg of β-carotene, mix well, and perform enzymatic hydrolysis at 30°C 7h, get 605kg enzymolyzate;

[0057] (2) Extraction and nanofiltration: Add 9075 kg of ethanol aqueous solution with a volume concentration of 30% to the 605 kg of enzymatic hydrolyzate obtained in step (1), stir and extract at room temperature for 6 hours, filter, and use a nanofiltration membrane with a molecular weight cut-off of 0.5 kDa to Filter to get 9000kg permeate;

[0058] (3) Concentration and crystallization: Concentrate 9000kg of the permeate obtained in step (2) with a falling film concentrator to a total solid mass concentration of 20%, cool to room temperature, and adjust the pH value with an aqueous solution of sulfuric acid with a mass concentration of 8%. to 5.7...

Embodiment 3

[0062] (1) Grinding and enzymatic hydrolysis of raw materials: Grind 150kg of cat bean raw materials with a low-temperature pulverizer until the particle size is 80 mesh, then add 150kg of water, 3kg of protease preparation and 0.15kg of tea polyphenols, mix well, and enzymatically hydrolyze at 20°C 12h, get 302kg enzymatic hydrolyzate;

[0063] (2) Extraction and nanofiltration: Add 3020 kg of methanol aqueous solution with a volume concentration of 50% to the 302 kg of enzymatic hydrolyzate obtained in step (1), stir and extract at room temperature for 8 hours, filter, and use a nanofiltration membrane with a molecular weight cut-off of 2.0 kDa to Filter to get 2800kg permeate;

[0064] (3) Concentration and crystallization: Concentrate 2800kg of the permeate obtained in step (2) with a falling film concentrator to a total solid mass concentration of 25%, cool to room temperature, and adjust the pH value with 10% acetic acid aqueous solution to 5.7, stirred and crystallized...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com