Copper base alloy powder preset coating for underwater laser cladding and preparation method of copper base alloy powder preset coating

A copper-based alloy, underwater laser technology, applied in the field of material science and engineering, can solve the problems of inclusions, poor metallurgical bonding of alloy coatings and substrates, etc., and achieves low cost, no cracks, inclusions, pores, and good forming quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

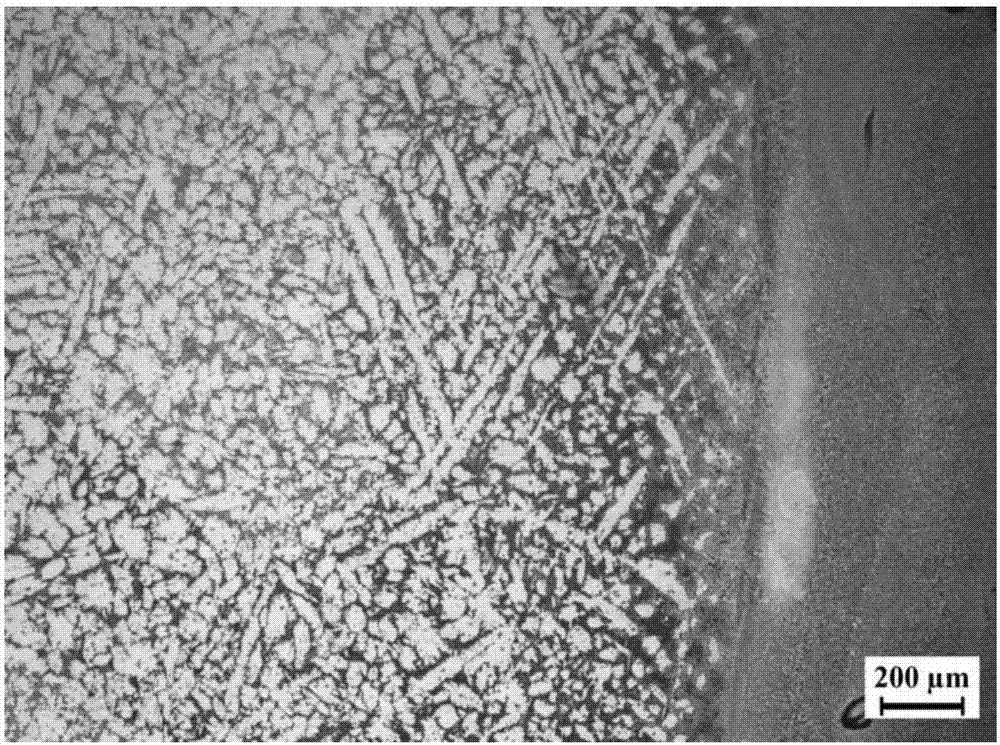

[0019] Specific Embodiment 1: The copper-based alloy powder pre-coating used for underwater laser cladding in this embodiment is composed of an alloy powder layer and a cladding protective coating, wherein the alloy powder layer is composed of copper-based alloy powder and α-cyano It is mixed with ethyl acrylate binder, and the cladding protective coating is composed of 40% to 45% CaF by mass percentage. 2 , 4%~5% CuO, 15%~18% CaCO 3 , 10% ~ 11% TiO 2 , 4% to 5% of Cu, 1% to 2% of Si, 2% to 3% of Al, 1% to 2% of Mn, 2% to 5% of ethyl cyanoacrylate and the rest Composition of activated carbon.

specific Embodiment approach 2

[0020] Embodiment 2: This embodiment differs from Embodiment 1 in that the thickness of the alloy powder layer is 1-2 mm.

specific Embodiment approach 3

[0021] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the thickness of the cladding protection coating is 0.2-0.5 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com