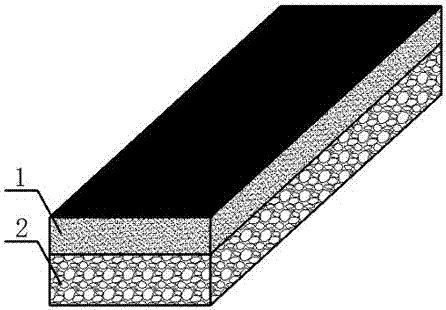

Novel temperature adjusting asphalt pavement structure

A technology of asphalt pavement and asphalt, which is applied in the field of new temperature-adjusted asphalt pavement structure, and can solve problems such as rutting that cannot be fundamentally solved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

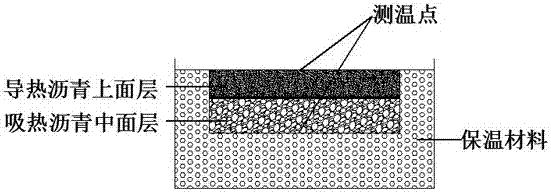

[0022] Determine the mass percentage of each dosage of ordinary asphalt mixture for the design of temperature-adjusted structural layer, 42% coarse aggregate (4.75mm ~ 13.2mm), 47.5% fine aggregate (0.075mm ~ 4.75mm), 5.7% slag powder and 4.8% 70# matrix asphalt.

[0023] Prepare polyethylene glycol / expanded perlite shape-setting phase change material, mix polyethylene glycol with 100 mesh expanded perlite,

[0024] Water bath at 90°C for 0.5h, vacuumize for 1h, heat filter for 24h, cool down, grind and sieve for later use.

[0025] The design of the heat-absorbing asphalt middle surface layer: keep the mass percentage of the coarse aggregate, mineral powder and asphalt of the asphalt mixture unchanged, adjust the mass of the fine aggregate (0.075mm to 4.75mm) to 39.2%, and the mixing ratio of the composite phase change material to 8.3 %.

[0026] Molding of the middle surface layer test piece: After preheating, the coarse and fine aggregates are mixed with a mixer for 90s, ...

Embodiment 2

[0031] Determine the mass percentage of each dosage of ordinary asphalt mixture for the design of temperature-adjusted structural layer, 42% coarse aggregate (4.75mm ~ 13.2mm), 47.5% fine aggregate (0.075mm ~ 4.75mm), 5.7% slag powder and 4.8% 70# matrix asphalt.

[0032] Prepare polyethylene glycol / expanded perlite shape-setting phase change material, mix polyethylene glycol with 100 mesh expanded perlite,

[0033] Water bath at 90°C for 0.5h, vacuumize for 1h, heat filter for 24h, cool down, grind and sieve for later use.

[0034] The design of the heat-absorbing asphalt middle surface layer: keep the mass percentage of the coarse aggregate, mineral powder and asphalt in the asphalt mixture unchanged, adjust the mass of the fine aggregate (0.075mm to 4.75mm) to 42.2%, and the mixing ratio of the composite phase change material to 5.3 %.

[0035] Molding of the middle surface layer test piece: After preheating, the coarse and fine aggregates are mixed with a mixer for 90s, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com