Preparation method, preparation device and production line for preparing integrated heat dissipation structure which is used for sealing liquid metal through one step

A liquid metal and preparation device technology, which is applied in the direction of modification through conduction and heat transfer, cooling/ventilation/heating modification, etc., can solve problems such as liquid metal leakage, achieve easy processing, simplify processing procedures, and avoid liquid metal leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A method for preparing an integrated heat dissipation structure for sealing liquid metal in one step, comprising the following steps:

[0055] (1) Dispensing:

[0056] Place the processed sealing frame 1 on a plane, and then drop liquid liquid metal 60 into the through hole 111;

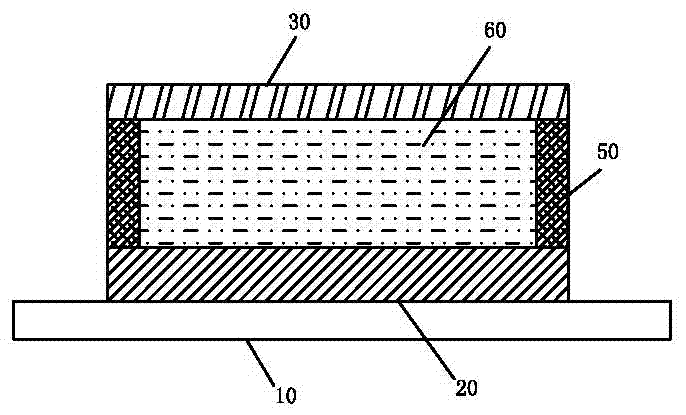

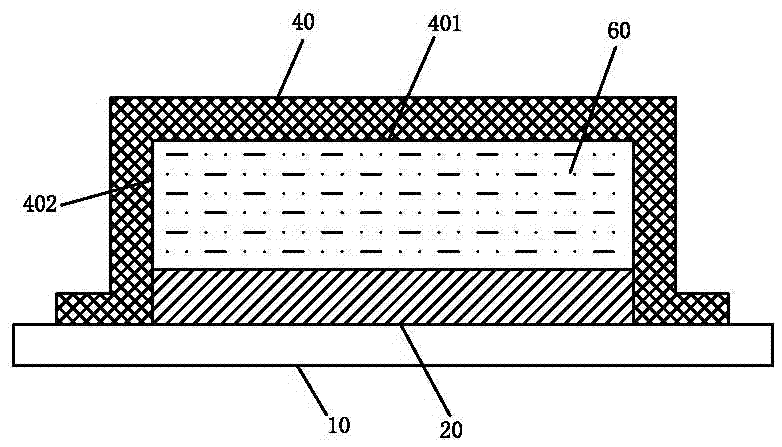

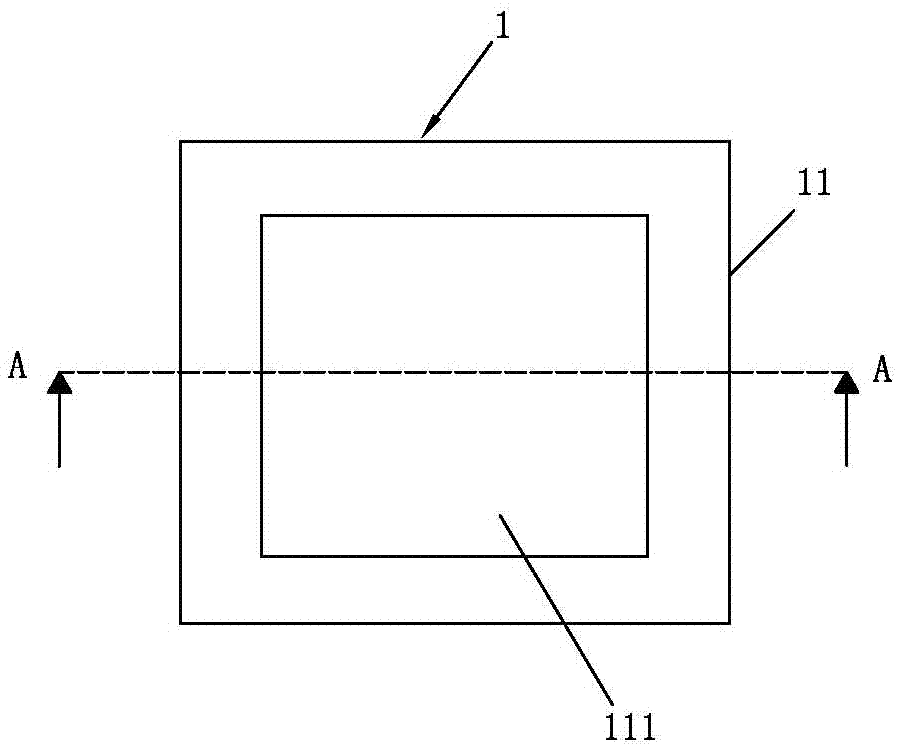

[0057] The structure of the sealing frame 1 is as follows image 3 and Figure 4 As shown, it includes a frame body 11 that matches the shape of the heating element 20, and thermally conductive adhesive layers 12 that are respectively arranged on the two surfaces of the frame body 11. The sealed frame body is provided with a through hole 111 for filling the liquid metal 60, and the frame The body 11 is a frame body 11 made of corrosion-resistant and aging-resistant materials.

[0058] (2) The liquid metal 60 and the sealing frame 1 are integrally formed by die-casting process:

[0059] The die-casting process is used to die-cast the liquid metal 60 in the through hole 111 through the press...

Embodiment 2

[0076] The preparation device for the integrated heat dissipation structure for sealing liquid metal is prepared in one step. This embodiment adopts the preparation method of Embodiment 1. The structure of the sealing frame 1 is exactly the same as that of Embodiment 1.

[0077] Such as Figure 8 As shown, the preparation device includes a conveying mechanism, a dispensing mechanism 2, a die-casting mechanism 3 and a cooling mechanism 4, wherein: the conveying mechanism is a belt conveying mechanism, and the dispensing mechanism 2 includes a dispensing cylinder 21, a point communicated with the dispensing cylinder 21 The glue head 22 and the X-axis servo manipulator 23 that drives the dispensing head 22 to move along the X-axis direction, the Y-axis servo manipulator (not shown in the figure) that moves along the Y-axis direction, and the Z-axis servo manipulator 24 that moves along the Z-axis direction (See X-axis, Y-axis, Z-axis directions Figure 8 indicated direction). T...

Embodiment 3

[0082]A production line for preparing the integrated heat dissipation structure for sealing liquid metal in one step, including a preparation device for the integrated heat dissipation structure for sealing liquid metal and a sealing frame manufacturing device, wherein: one step is for preparing the integrated heat dissipation structure for sealing liquid metal The preparation device and preparation method of the structure are exactly the same as those in Example 2, and the structure of the sealing frame is exactly the same as that in Example 1, and will not be repeated in this example.

[0083] Such as Figure 9 As shown, in this embodiment, the sealing frame manufacturing device 5 includes an extruder 51, a calender 52, a gluing mechanism 53, and a cutting mechanism 54, wherein the corrosion-resistant and aging-resistant plastic raw materials pass through the extruder 51 and the calender in sequence. After 52, the sheet-like board is obtained. The glue-applying mechanism 53 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com