Low phosgene content boron trichloride production device and method

A technology of boron trichloride and production equipment, which is applied in the direction of boron halide compounds, boron halides, etc., can solve problems such as inability to reach, and achieve the effects of reducing possibility, reducing residual chlorine impurity content, and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

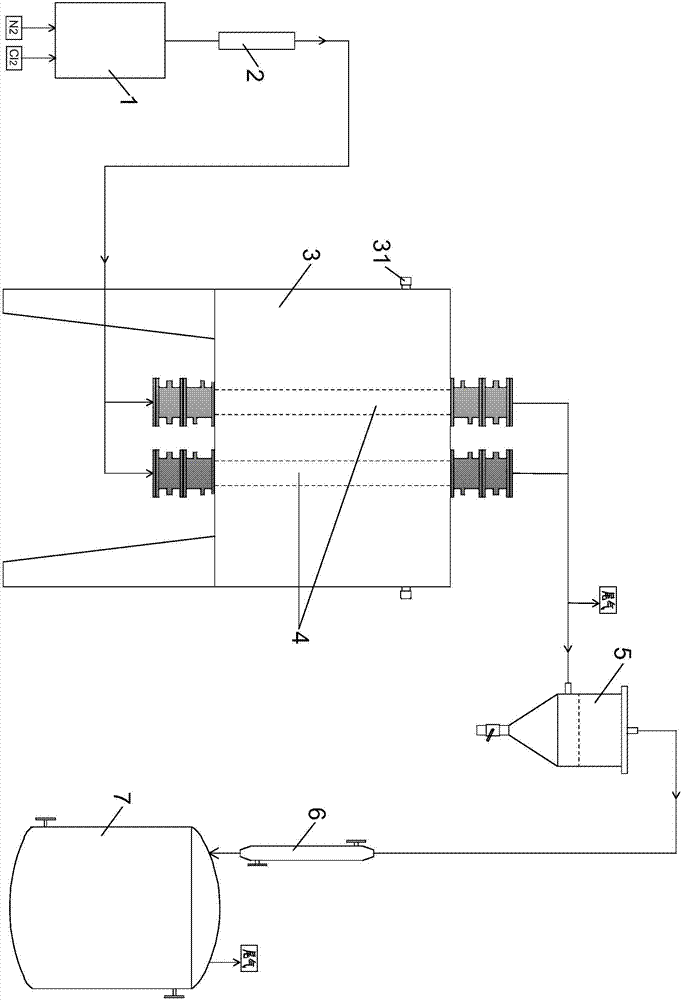

Embodiment 1

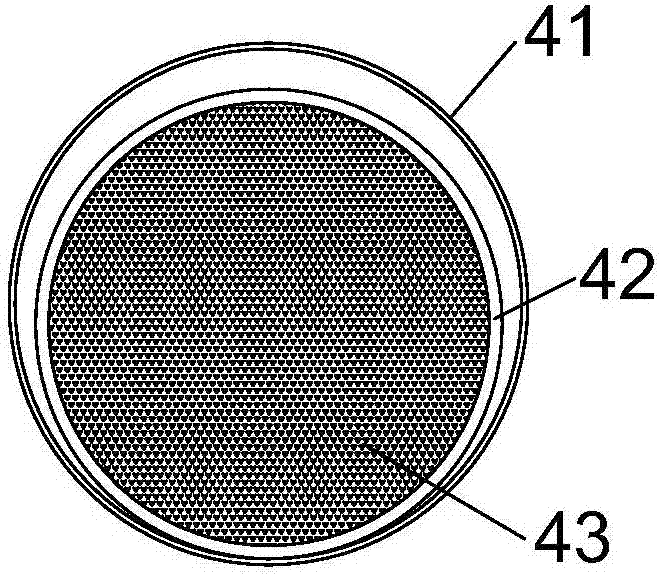

[0042] 6 kg, boron carbide particles 43 with a purity of 97% after pickling and a particle size of 1 to 3 mm are packed into two double-layer reaction tubes 4 of the vertical reaction furnace 3 (the total length of the graphite ring 42 accounts for about 2 / 3 of the total length of the quartz tube 41) , the boron carbide particles 43 loading amount is about 10 mm above the observation hole 32 of the vertical reaction furnace 3, and the average effective reaction cross-sectional area of the double-layer reaction tube 4 is 100 cm 2 After assembling the reaction system, the vertical reaction furnace 3 is heated up to 300°C, and the reaction system is purged by nitrogen (pressure 0.1MPa, flow rate 100m 3 / h) for 1 hour to replace the moisture and air in the system; the double-layer reaction tube 4 continues to heat up to 650 ° C, and after reaching the reaction start temperature, the liquid chlorine is vaporized and buffered and then enters the dryer 1 through a particle size of 1...

Embodiment 2

[0046] 6 kg, boron carbide particles 43 with a purity of 97% after pickling and a particle size of 1 to 3 mm are packed into two double-layer reaction tubes 4 of the vertical reaction furnace 3 (the total length of the graphite ring 42 accounts for about 2 / 3 of the total length of the quartz tube 41) , the boron carbide particles 43 loading amount exceeds about 10 mm above the observation hole 31 of the vertical reaction furnace 3, and the average effective reaction cross-sectional area of the double-layer reaction tube 4 is 100 cm 2 After assembling the reaction system, the vertical reaction furnace 3 is heated up to 300°C, and the reaction system is purged by nitrogen (pressure 0.2MPa, flow rate 200m 3 / h) for 1 hour to replace the moisture and air in the reaction system; the vertical reaction furnace 3 continues to heat up to 750 ° C, and after reaching the reaction start temperature, the liquid chlorine is vaporized and buffered and then enters the dryer 1 through a parti...

Embodiment 3

[0050] 6 kg, boron carbide particles 43 with 97% purity after pickling and a particle size of 1 to 3 mm are packed into 2 double-layer reaction tubes 4 of the vertical reaction furnace 3 (the total length of the graphite ring accounts for about 2 / 3 of the total length of the quartz tube), carbonized The amount of boron particles 43 loaded is about 10 mm above the observation hole 31 of the vertical reaction furnace 3, and the average effective reaction cross-sectional area of the double-layer reaction tube 4 is 100 cm 2 After assembling the reaction system, the vertical reaction furnace 3 is heated to 300°C, and the reaction system is purged by nitrogen (pressure 0.3MPa, flow 300m 3 / h) for 1 hour to replace the moisture and air in the reaction system; the vertical reaction furnace 3 continues to heat up to 850 ° C, and after reaching the reaction start temperature, the liquid chlorine is vaporized and buffered and then enters the dryer 1 through a particle size of 1 mm and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com