Process control system of turn-barrel shaft furnace

A process control, rotating sleeve technology, applied in furnaces, vertical furnaces, furnace types, etc., can solve the problems of loss of quality of production products, indeterminate differences, and different product quality, and achieve economical, practical and universal application. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the objectives, technical solutions, and advantages of the embodiments of the present invention clearer, the following describes the technical solutions in the embodiments of the present invention clearly and completely in conjunction with the drawings in the embodiments of the present invention:

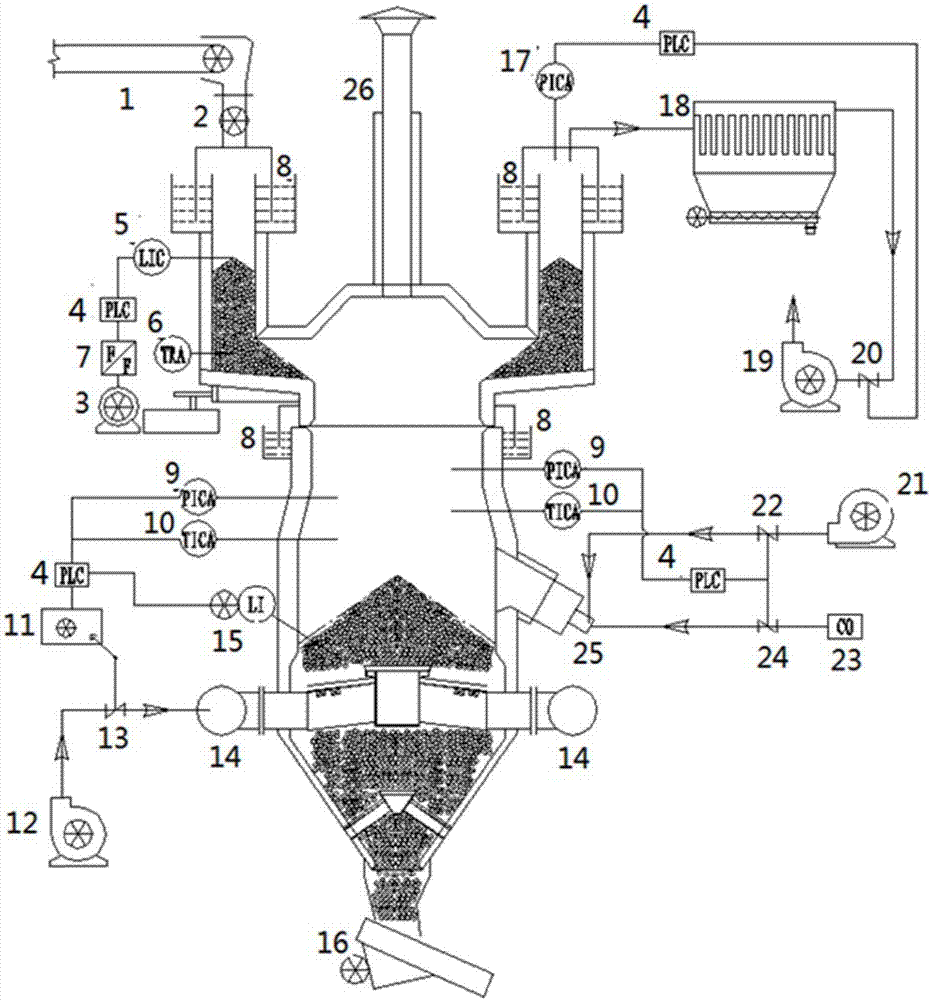

[0041] Such as Figure 1-6 Shown: Rotary sleeve shaft furnace process control system, mainly including: burning chamber material level control unit, target value 2.3±0.5m, such as figure 1 , Use the radar level meter to detect the material surface height of the shaft furnace baking chamber, and the signal level detection transmitter 5 is connected to the PLC controller 4.

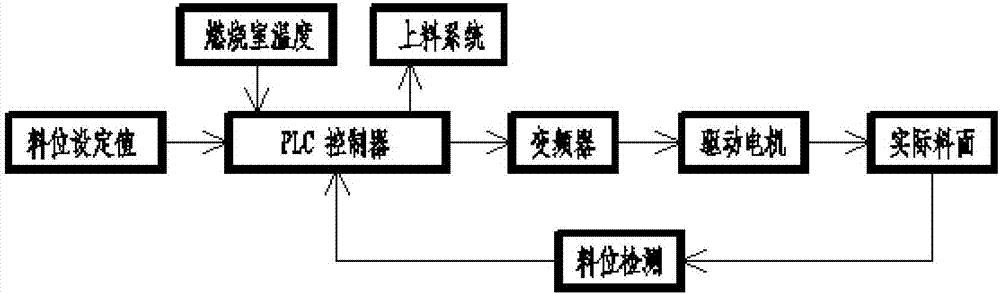

[0042] PLC controller 4 uses PID controller for closed-loop control such as figure 2 As shown, according to the set value of the material level, the material level of the baking chamber is controlled at a constant position. The PLC controller 4 outputs the signal to the frequency converter 7, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com