Supermolecule cleaning fracturing fluid system with adjustable and controllable viscoelasticity and preparation method of supermolecule cleaning fracturing fluid system

A clean fracturing fluid and clean fracturing technology, applied in chemical instruments and methods, mining fluids, earthwork drilling, etc., can solve problems such as poor temperature resistance and complex synthesis process, and avoid adsorption damage and synthesis technology. Simple, high temperature resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] An adjustable supramolecular cleaning fracturing fluid system and a preparation method thereof, comprising the following components:

[0033] In terms of mass percentage: 1.0-6.0% cationic surfactant, 0.2-1.0% organic polybasic acid, 0.1-2.0% inorganic salt, 0.1-1.0% amphiphilic polymer, 98.6-90.0% water.

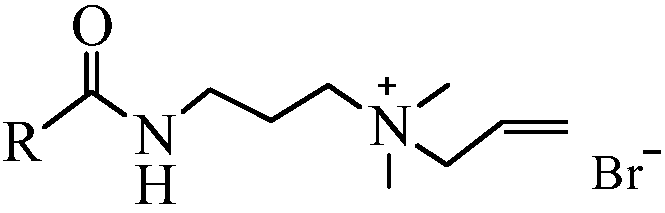

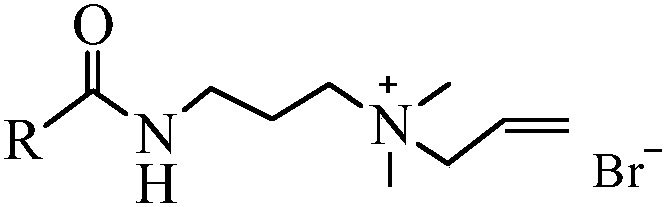

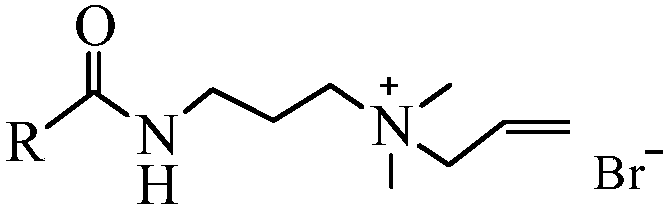

[0034] The cationic surfactant is an ultra-long chain fatty amide cationic surfactant with the following structure:

[0035]

[0036] Where: R is a saturated and unsaturated alkyl chain with carbon number C≥16

[0037] The preparation method of ultra-long-chain fatty amide cationic surfactant is as follows:

[0038] Put 5.0-50.0g of fatty tertiary amide and 2.5-25.0g of potassium carbonate into a single-mouth bottle, add 20.0-100.0mL of absolute ethanol to dissolve, raise the temperature to 50-70°C, slowly add 2.0-15.0g of bromopropene dropwise, drop After the addition was completed, the reaction was carried out for 7 to 24 hours, and the solid product was obtai...

Embodiment 1

[0046] The preparation method of erucamide propyl allyl ammonium bromide:

[0047] Take 26.0 g of erucamidopropyl dimethyl tertiary amine in a single-necked bottle, add 40 mL of absolute ethanol as a solvent, raise the temperature to 60 ° C, slowly add 8.0 g of bromopropene dropwise, continue the reaction for 12 hours, and distill under reduced pressure to obtain a yellow viscous Liquid, add acetone to dissolve, then refrigerate at 0°C for 10h to precipitate a white solid, filter, and dry to obtain the final product with a yield of 85-92%.

Embodiment 2

[0049]Prepare sodium chloride mineralized water with a salinity of 5000mg / L, stir it for 15 minutes to dissolve it completely; add 0.1wt% amphiphilic polymer to the configured mineralized water (the amphiphilic polymer is patented CN201710086348.0 The amphiphilic polymer product prepared in Example 1), stirred for 200 minutes, mixed uniformly, then added 0.5wt% citric acid, stirred for 10 minutes, mixed uniformly to obtain a mixed solution, and then added 2.0wt% of Example 1 The prepared erucamide propyl allyl ammonium bromide was stirred for 20 minutes and mixed uniformly to obtain a supramolecular clean fracturing fluid; the clean fracturing fluid was placed in the rheometer drum, at pH=6.2, 90°C, 170s -1 Under shearing for 120 minutes, the viscosity is kept stable at 50-55mPa·s, the breaking time of kerosene is 40 minutes, and the apparent viscosity of the breaking liquid is 4mPa·s. At pH=9.4, 90°C, 170s -1 Under shearing for 120 minutes, the viscosity is maintained at 65...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com