A method for regenerating positive photoresist of parts of lithography machine in yellow light process

A technology of yellow light process and parts, applied in the field of positive photoresist regeneration of parts of yellow light process lithography machine, can solve the problems of parts aging, poor cleaning effect of cleaning agent and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

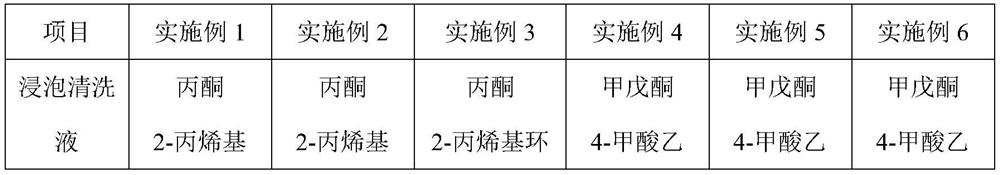

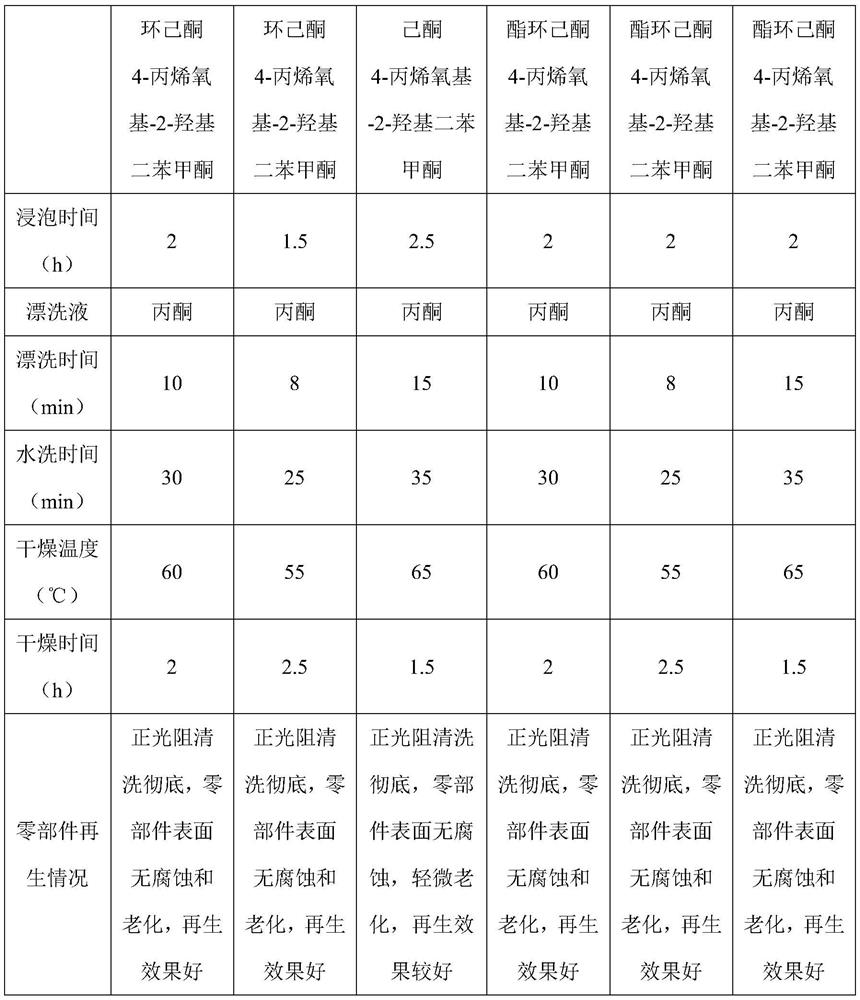

[0019] Below in combination with Table 1, specific embodiments of the present invention will be described in detail.

[0020] Table 1 shows the condition parameters of each step of the positive photoresist regeneration method of a yellow light process photolithography machine part in Embodiment 1-6.

[0021] Each step reagent and parameter condition described in the embodiment of table 1

[0022]

[0023]

[0024] The method for regenerating the positive photoresist of the parts of the yellow-light process photolithography machine according to the present invention has the optimal soaking time of 2 hours, the rinsing liquid is acetone, the optimal rinsing time is 10 minutes, the optimal washing time is 30 minutes, and the ultra-clean drying temperature is optimal. The temperature is 60°C, and the time is 2h.

[0025] The method for regenerating the positive photoresist of a part of a yellow-light process photolithography machine described in Embodiment 1-6 includes the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com