High reflection gain type photovoltaic packaging glue film and application

A packaging adhesive film and gain-type technology, which is applied in the field of high-reflection gain-type photovoltaic packaging adhesive film, can solve the problems of small contribution to the reduction of cost of electricity and high cost of raw materials, and achieve reduction of cost of electricity, insulation performance and weather resistance Excellent, cost-reducing effect of reflective materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The packaging film manufacturing process is as follows:

[0055] First, ethylene-vinyl acetate copolymer (U.S. DuPont) 85wt%, modification aid 3-(methacryloyl chloride) propyltrimethyloxysilane (Shanghai Chunan International Trade Co., Ltd.) 10wt%, UV Auxiliary 2-(2'-hydroxyl-3'-tert-butyl-5'-methylphenyl)-5-chlorobenzotriazole (Jinan Bangde Chemical Technology Co., Ltd.) 2wt%, anti-thermal oxygen Aging agent 2,6-di-tert-butyl-4-methylphenol (Shenghe Chemical Co., Ltd.) 1.5wt%, initiator benzoyl peroxide (Chengdu Gracia Chemical Technology Co., Ltd.) 1.5wt%, after mixing After being extruded at 60-90°C, it is cast into a film to obtain a 450-micron-thick encapsulation layer.

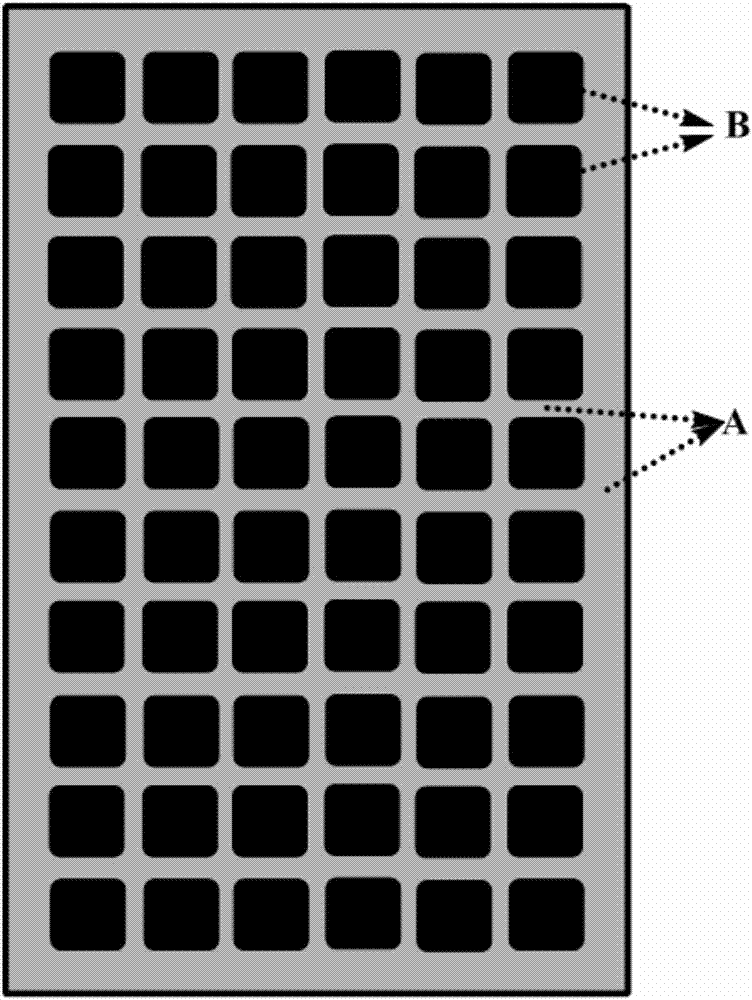

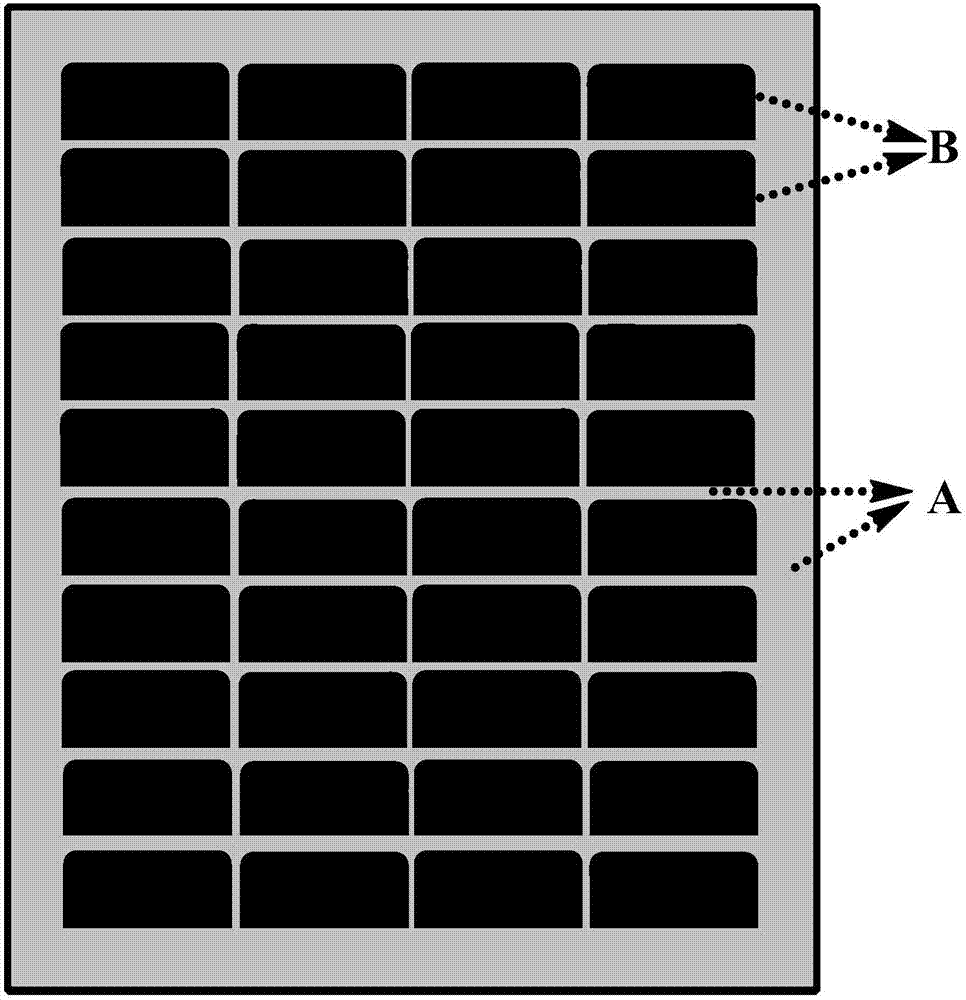

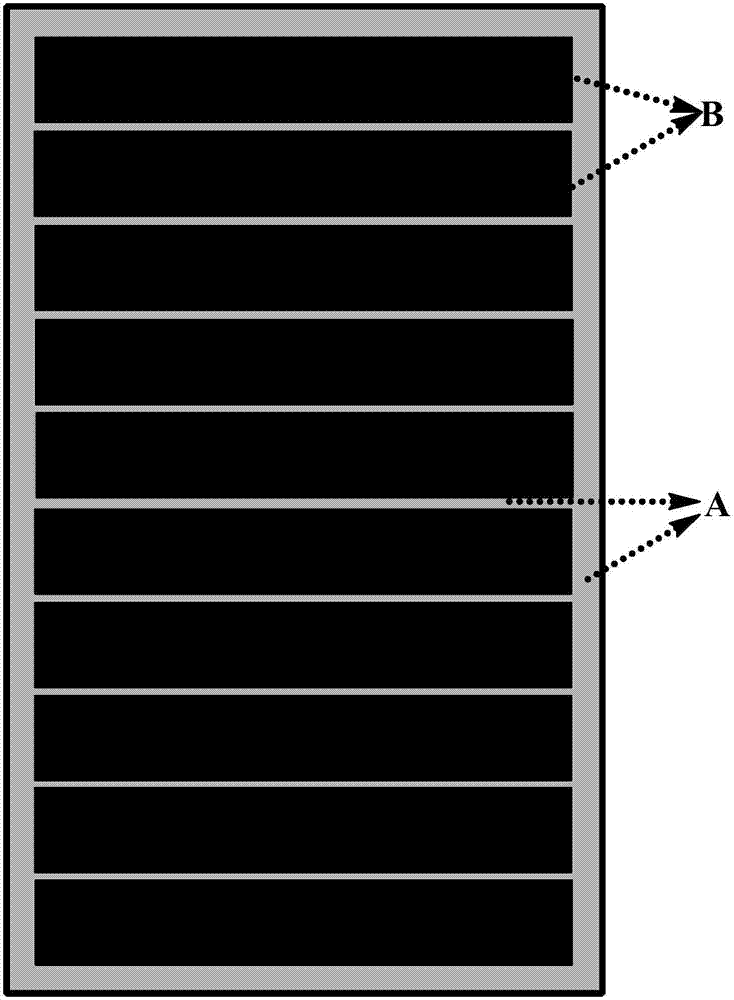

[0056] Then, spray-coat a reflective layer with a thickness of 160 microns on one side of the encapsulation layer on the coating line with the shape of the reflective area designed in advance. The ingredients of the reflective layer coating are 75wt% of hydroxyl acrylic resin (Mitsui Chemicals C...

Embodiment 2

[0058] First, ethylene-octene copolymer (U.S. Dow Chemical) 60wt%, modification additive 3-(2,3-glycidyloxy) propylmethyldiethoxysilane (Jinan Langhua Chemical Co., Ltd. ) 10wt% and vinyl trimethoxysilane (Jinan Langhua Chemical Co., Ltd.) 20wt%, UV additive 2,4-dihydroxybenzophenone (Shanghai Zhixin Chemical Co., Ltd.) 6wt%, anti-thermal oxygen aging agent 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (Dongguan Varisi Chemical Co., Ltd.) 3wt%, initiator 2,5-dimethyl-2,5-bis (tert-butyl peroxy)-hexane (Guangzhou Qiansheng Trading Co., Ltd.) 1wt%, mixed evenly, extruded at 80-120° C., and cast to form a film to obtain a 200-micron-thick encapsulation layer.

[0059] Then, a reflective layer with a thickness of 5 microns is coated on one side of the encapsulation layer on a coating line with a pre-designed shape of the reflective area. The reflective layer coating ingredients are polycaprolactone diol (Dacel Corporation, Japan) 60wt%, acrylic vinyl ester resin (Mitsubishi ...

Embodiment 3

[0061] First, ethylene-methyl acrylate copolymer (U.S. DuPont Chemical) 70wt%, modified auxiliary vinyltrimethoxysilane (Shanghai Chun'an International Trade Co., Ltd.) 18wt%, ultraviolet auxiliary agent 2-[4-[2 -Hydroxy-3-dodecyloxypropyl]oxy]-2-hydroxyphenyl]-4,6-bis(2,4-dimethylphenyl)-1,3,5-triazine ( Jinan Bond Chemical Technology Co., Ltd.) 8wt%, anti-thermal oxygen aging agent 2-[4-[2-hydroxy-3-dodecyloxypropyl]oxyl]-2-hydroxyphenyl]-4,6 - Bis(2,4-dimethylphenyl)-1,3,5-triazine (Sanhe Chemical Co., Ltd.) 2.5wt%, initiator o,o-tert-amyl-o-(2-ethyl Hexyl)-mono-peroxycarbonate (Chengdu Gracia Chemical Technology Co., Ltd.) 1.5wt%, mixed evenly, extruded at 80-120°C, and cast to form a film to obtain a 200 micron thick encapsulation layer.

[0062] Then, a reflective layer with a thickness of 180 microns is coated on one side of the encapsulation layer on a coating line with a pre-designed shape of the reflective area. The ingredients of the reflective layer coating are 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com