Production technology of mushroom soy sauce

A production process and technology of soy sauce, applied in food science, food ingredients, applications, etc., can solve the problems affecting the quality uniformity of mushroom soy sauce, the ability of soy mash to inhibit miscellaneous bacteria, and affect the flavor of mushroom soy sauce, etc., so as to improve the quality of soy sauce , rich taste, good for growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

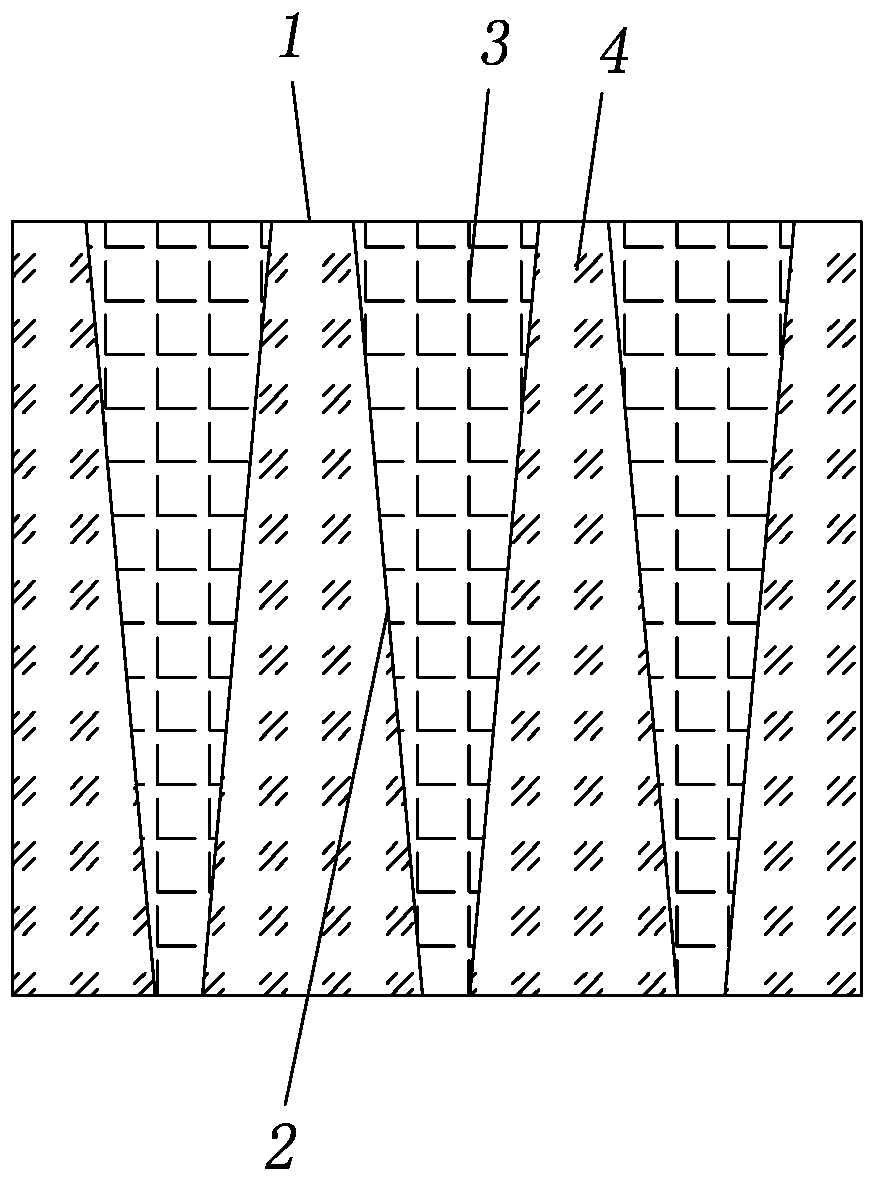

Image

Examples

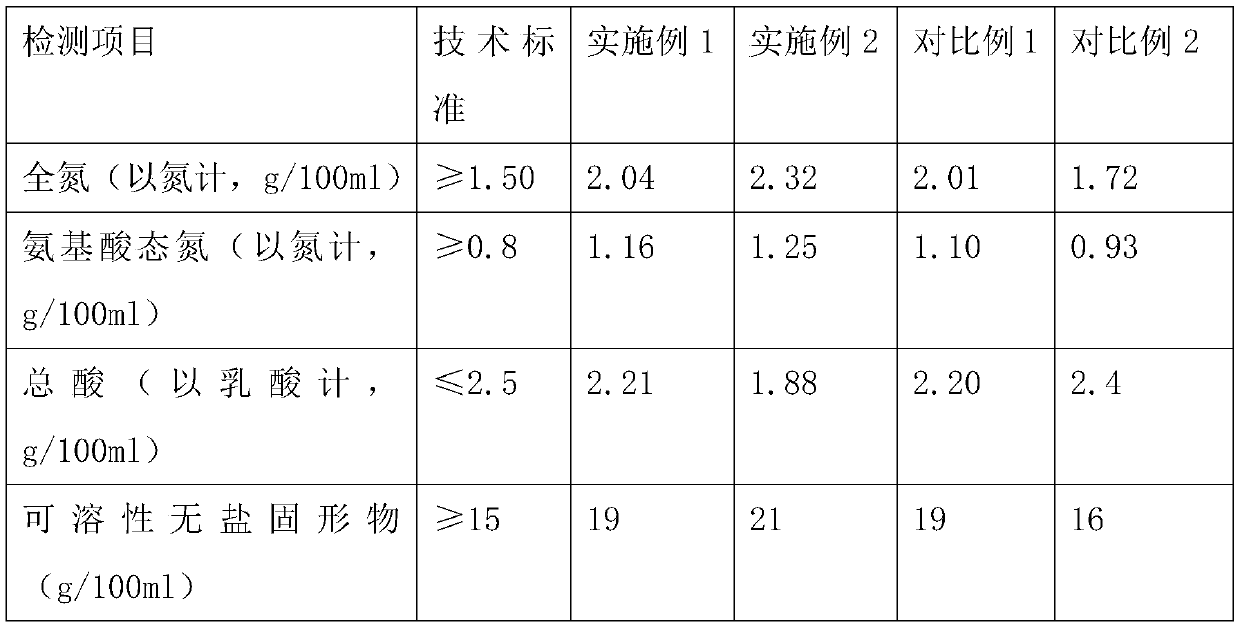

Embodiment 1

[0019] The preparation technology of the mushroom soy sauce that present embodiment provides, comprises the steps:

[0020] A. Raw material preparation: Soybean oil is extracted to obtain bean cake, and bean cake is crushed to obtain soybean meal; wheat flour is screened to remove impurities, and wheat flour is crushed; wheat bran is screened to remove impurities to obtain 50 mesh wheat bran; soybean meal, wheat bran and wheat flour are pressed The ratio of 6:3:1 is mixed to get the mixture;

[0021] B. Cooking: Add water to the mixture, the volume ratio of the mixture to water is 1.2:1, moisten the water for 10 minutes, mix the mixture evenly while moistening, then put it into the steaming tank for cooking, at 0.25MPa Cook under pressure for 15 minutes to obtain clinker, and cool to 35°C;

[0022] C, koji making: the cooled grog is inoculated with Aspergillus oryzae, soot and acriflavine, the quality of Aspergillus oryzae, soot, and acriflavine is 0.1% of the clinker quality...

Embodiment 2

[0026] The preparation technology of the mushroom soy sauce that present embodiment provides, comprises the steps:

[0027] A. Raw material preparation: Soybean oil is extracted to obtain bean cake, and bean cake is crushed to obtain soybean meal; wheat flour is screened to remove impurities, and wheat flour is crushed; wheat bran is screened to remove impurities to obtain 50 mesh wheat bran; soybean meal, wheat bran and wheat flour are pressed The ratio of 6:3:1 is mixed to get the mixture;

[0028] B. Cooking: Add water to the mixture, the volume ratio of the mixture to water is 1.6:1, moisten the water for 15 minutes, mix the mixture well while moistening, then put it into the steaming tank for cooking, at 0.25MPa Cook under pressure for 20 minutes to obtain clinker, and cool to 35°C;

[0029] C, koji making: the cooled clinker is inoculated with Aspergillus oryzae, soot and acriflavine, the quality of Aspergillus oryzae, soot, and acriflavine is 0.15% of the clinker quali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com