A kind of preparation method and application of hollow magnetic CO/carbon nanotube

A carbon nanotube and magnetic technology, which is applied in the field of preparation of hollow magnetic Co/carbon nanotubes, can solve problems such as limiting the practical application of materials, and achieve the effects of avoiding loss and unsafe factors, novel magnetic properties, and complex process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for preparing hollow magnetic Co / carbon nanotubes of the present embodiment comprises the following steps:

[0036] (1) Weigh 3.3g of dicyandiamide and 0.8g of cobalt acetate, add to 45ml of absolute ethanol, and magnetically stir the solution at 58°C for 2.5 hours;

[0037] (2) The solution was stirred at 58°C for 22 hours;

[0038] (3) Put the solution in an oven at 43°C for drying, leaving a solid powder;

[0039] (4) The solid powder is placed in a high-temperature tube furnace, under N 2 Calcined at 850°C for 0.5 hours under atmosphere, with a heating rate of 9°C / min;

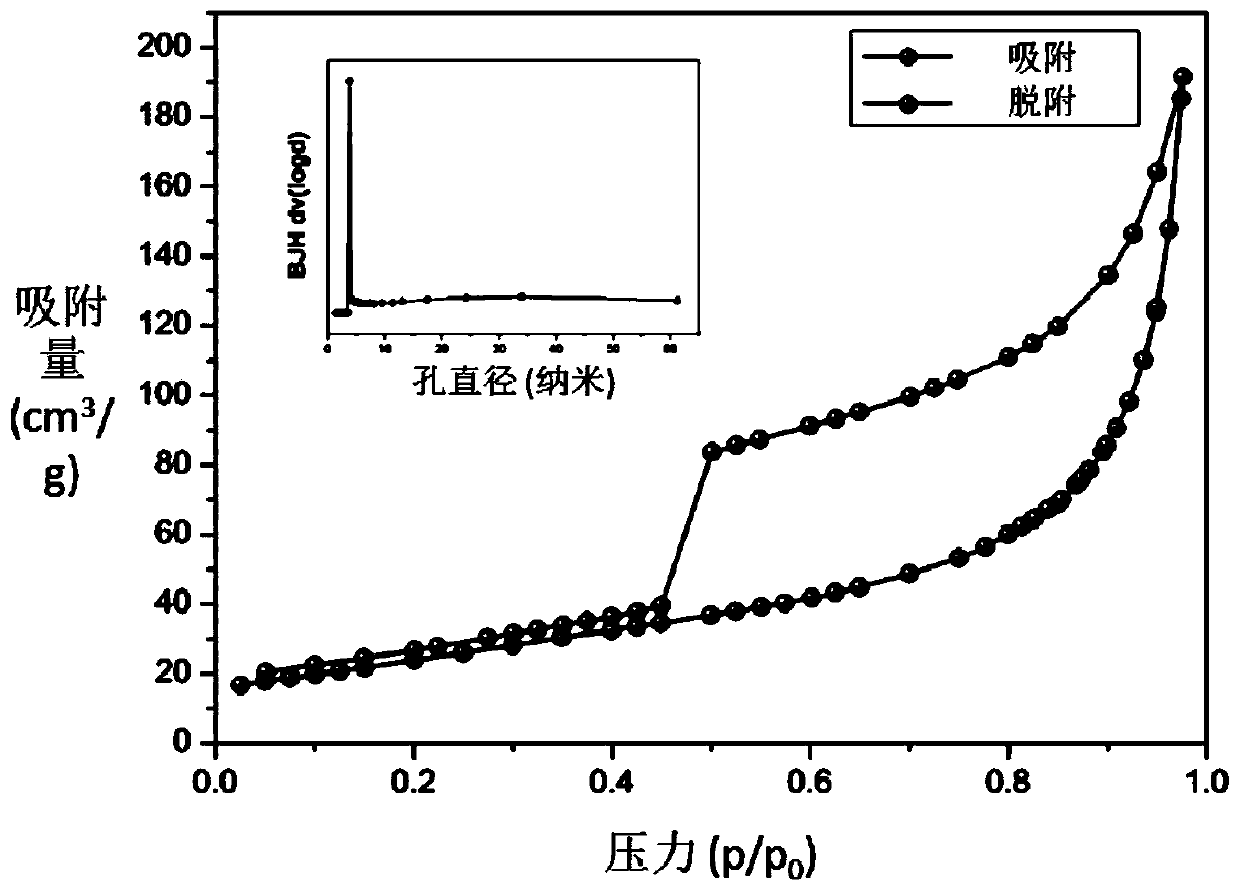

[0040] (5) After natural cooling to 18°C, a hollow magnetic Co / carbon nanotube with a uniform shape and a bamboo-shaped tubular shape was obtained. The hollow magnetic Co / carbon nanotube is a mesoporous material with a nanoparticle surface area of 131.6 m 2 / g, the pore volume is 0.296cm 3 / g, the average pore diameter of the particles is 13.47nm.

Embodiment 2

[0042] A method for preparing hollow magnetic Co / carbon nanotubes of the present embodiment comprises the following steps:

[0043] (1) Weigh 3.7g of dicyandiamide and 1.2g of cobalt acetate, add them to 55ml of absolute ethanol, and magnetically stir the solution at 62°C for 3.5 hours;

[0044] (2) The solution was stirred at 62°C for 26 hours;

[0045] (3) Put the solution in an oven at 47°C to dry, leaving a solid powder;

[0046] (4) The solid powder is placed in a high-temperature tube furnace, under N 2 Calcination at 950°C for 1.5 hours under atmosphere, with a heating rate of 11°C / min;

[0047] (5) After natural cooling to 25°C, a hollow magnetic Co / carbon nanotube with a uniform shape and a bamboo-shaped tubular shape was obtained. The hollow magnetic Co / carbon nanotube is a mesoporous material with a nanoparticle surface area of 131.6 m 2 / g, the pore volume is 0.296cm 3 / g, the average pore diameter of the particles is 13.47nm.

Embodiment 3

[0049] A method for preparing hollow magnetic Co / carbon nanotubes of the present embodiment comprises the following steps:

[0050] (1) Weigh 3.5g of dicyandiamide and 1.0g of cobalt acetate, add them to 50ml of absolute ethanol, and stir the solution magnetically at 60°C for 3 hours;

[0051] (2) The solution was stirred at 60°C for 24 hours;

[0052] (3) Put the solution in an oven at 45°C for drying, leaving a solid powder;

[0053] (4) The solid powder is placed in a high-temperature tube furnace, under N 2 Calcination at 900°C for 1 hour under atmosphere, with a heating rate of 10°C / min;

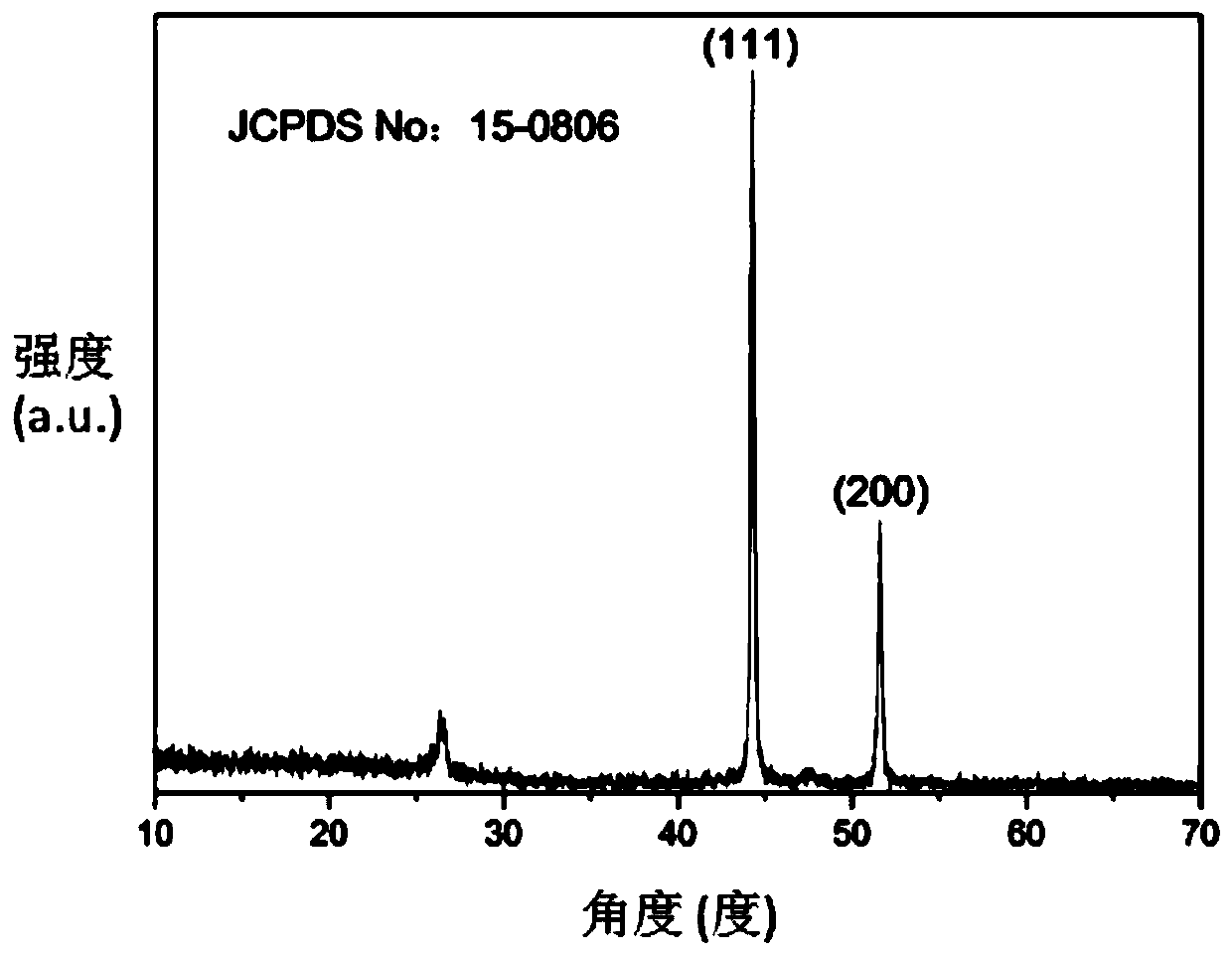

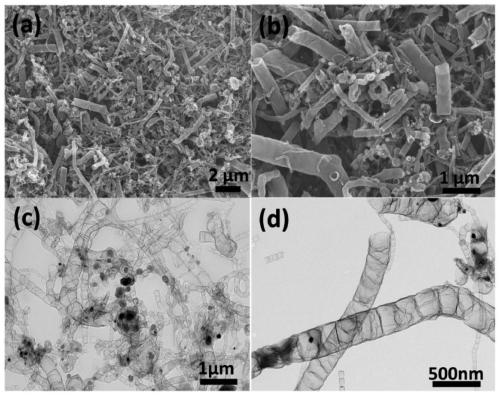

[0054] (5) After natural cooling to 24°C, hollow magnetic Co / carbon nanotubes are obtained; figure 1 is the X-ray diffraction of Co / CNTs picture, figure 2 is the SEM of Co / CNTs (Fig. 2a and figure 2 b) and transmission electron microscope TEM ( figure 2 c and figure 2 d) Figure, from figure 2 a and figure 2 In the SEM image of b, it can be seen that Co / carbon nanotubes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com