Low-permeability thermal-insulation film with high weatherability and high definition, and preparation method thereof

A high-definition heat-transmitting film technology, which is applied in the preparation of composite heat-insulating films, low-permeable heat-insulating films, and the field of low-permeable heat-insulating films, can solve the problems of fading and weather resistance of low-permeable heat-insulating films, and achieve High weather resistance, good novelty and creative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037]Selection of PET base film: Select Melinex406, an optical-grade PET base film from DuPont Company, with a thickness of 23 microns. Both sides of the base film are pre-coated, which can improve the composite strength and the adhesion of the scratch-resistant layer.

[0038] Preparation of carbon black slurry: Weigh 4 parts of carbon black with a particle size of 15 nanometers, 2.8 parts of dispersant and 93.2 parts of ethyl acetate, first mix and stir the dispersant and solvent in the ball mill pre-mixing tank for 20 minutes, and then pass into Grind in the grinding chamber of a ball mill, and gradually add carbon black, and make a carbon black slurry after 10 hours of grinding.

[0039] Preparation of blue pigment slurry: Weigh 10 parts of blue pigment, 10 parts of dispersant and 80 parts of methyl ethyl ketone, mix and stir the dispersant and solvent in the ball mill pre-mixing tank for 20 minutes, and then pass it into the grinding chamber of the ball mill Grinding and...

Embodiment 2

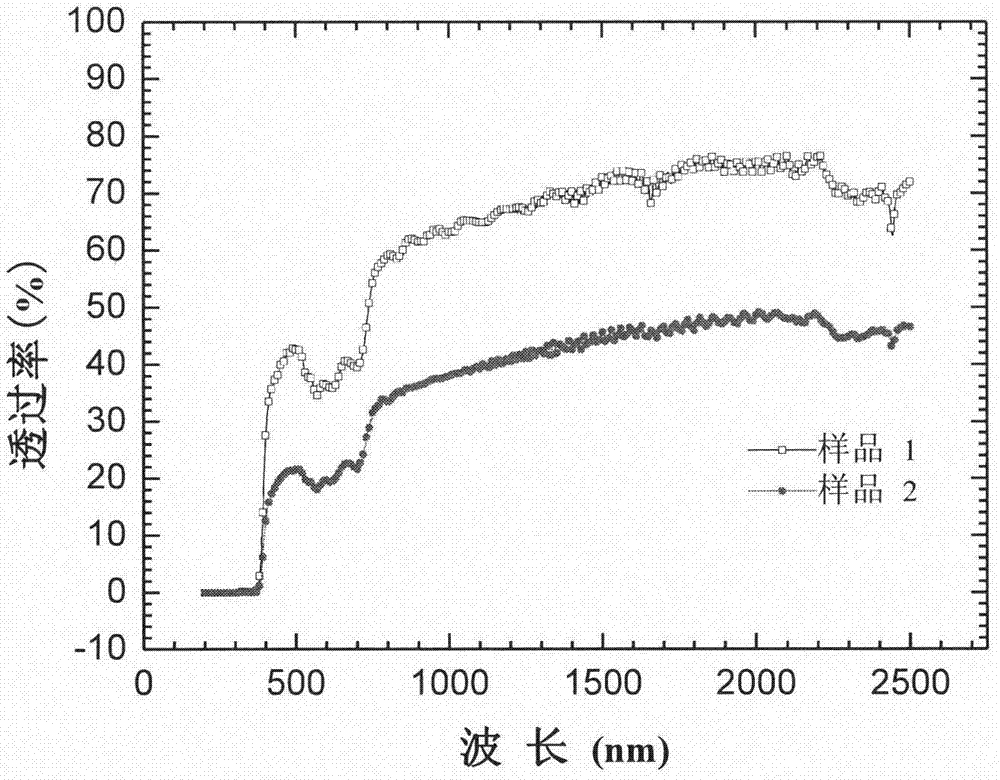

[0044] Embodiment 2 is all the same with the used PET film and slurry of embodiment 1, and the difference is that the ratio of carbon black, blue pigment and red pigment in the composite functional coating is not the same, specifically as follows:

[0045] Preparation of Composite Functional Coating B: Weigh 9.73 parts, 1.37 parts and 1.73 parts of each of the carbon black slurry, blue pigment slurry and red pigment slurry prepared above, and the composite adhesive Cytec one-component acrylic pressure-sensitive adhesive 265 (30% solid content) 44.35 parts, ethyl acetate 31.69 parts, butanone 4.27 parts, diacetone alcohol 6.86 parts. First add the solvent to the mixing tank, then add the pigment slurry, stir for 20 minutes, and finally add the composite glue gradually and stir 60 parts to make a composite functional coating.

[0046] Preparation of low-permeability heat-insulating film: apply the above-mentioned composite functional coating on either side of the first base film...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com