Method for removing nitrate nitrogen in water, electrode biofilm culturing method, electrode and device

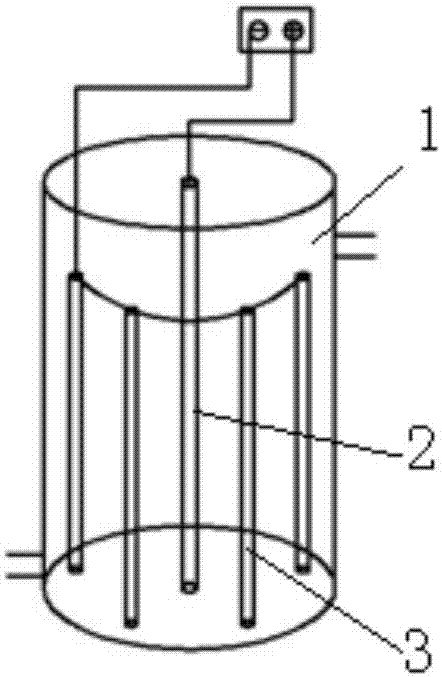

A technology of nitrate nitrogen and film hanging method, applied to electrodes and devices, in the field of removing nitrate nitrogen from water, can solve the problems of weak adsorption force between microorganisms and electrodes, not too high nitrate removal rate, slow film hanging speed, etc. , to achieve the effect of improving the film hanging efficiency, improving the nitrate removal efficiency, and enhancing the utilization rate of the current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

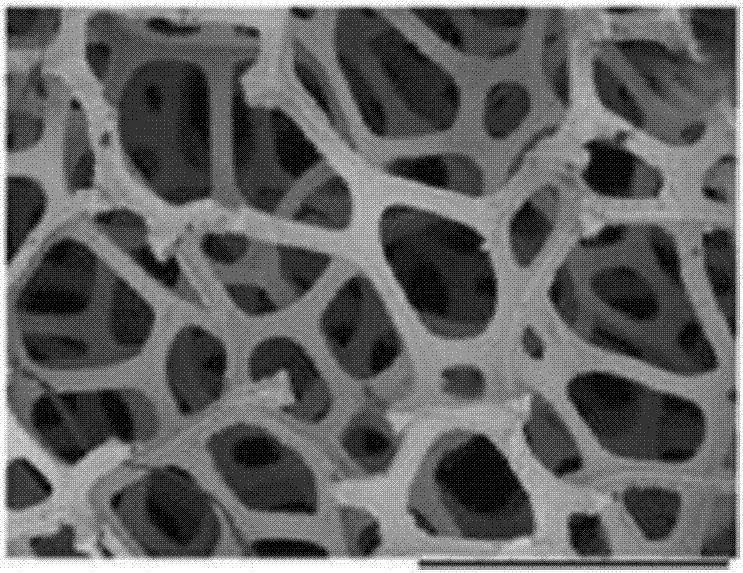

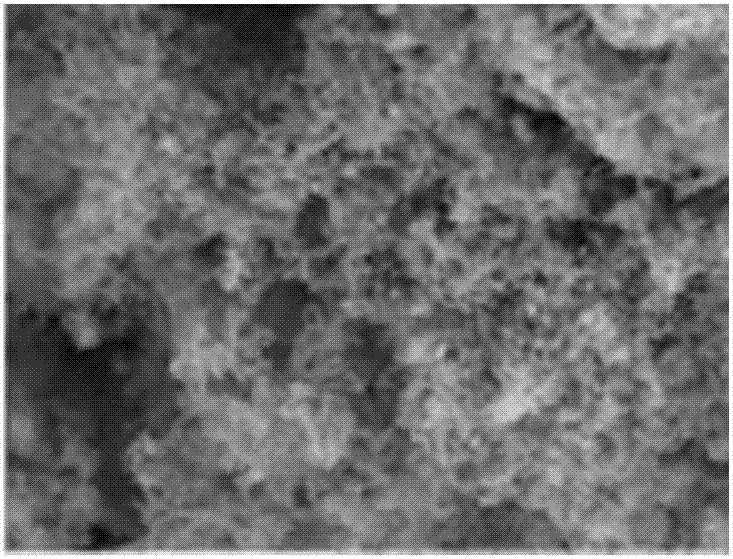

[0052] The process of magnetization modification of foam nickel electrode comprises the following steps:

[0053] (1) Magnetic Nano Fe 3 o 4 Preparation of:

[0054] 4-6g of Fecl 3 .6H 2 O and 2.78 g of FeCl 2 .7H 2 Dissolve O in 100ml of pure water, then add 2g-3g of polyethylene glycol, stir magnetically, heat to 80-100°C, then add 15ml-20ml of NH 3 .H 2 O, in a nitrogen atmosphere at 60-80°C, react under magnetic stirring conditions for 30-40min, the product is separated by a magnet, washed with pure water, and then vacuum-dried for 6-8h to obtain PEG-Fe 3 o 4 NPS;

[0055] (2) placing the nickel foam after ultrasonic cleaning in a phosphate buffer solution with a concentration of 0.1M and a pH of 7.0 for cyclic voltammetry scanning, and the scanning potential is 0-2.5V;

[0056] (3) 3mg of PEG-Fe 3 o 4 Add NPS into water and ultrasonically disperse for 20-30min to obtain a super-dispersed solution, then apply it on the surface of the activated nickel foam elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com