High-strength soluble nanoscale particle temporary plugging agent

A soluble, nano-scale technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve problems such as insufficient strength, inability to effectively seal small pore fractures, proppant regurgitation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with specific examples, but the following examples do not limit the present invention in any way.

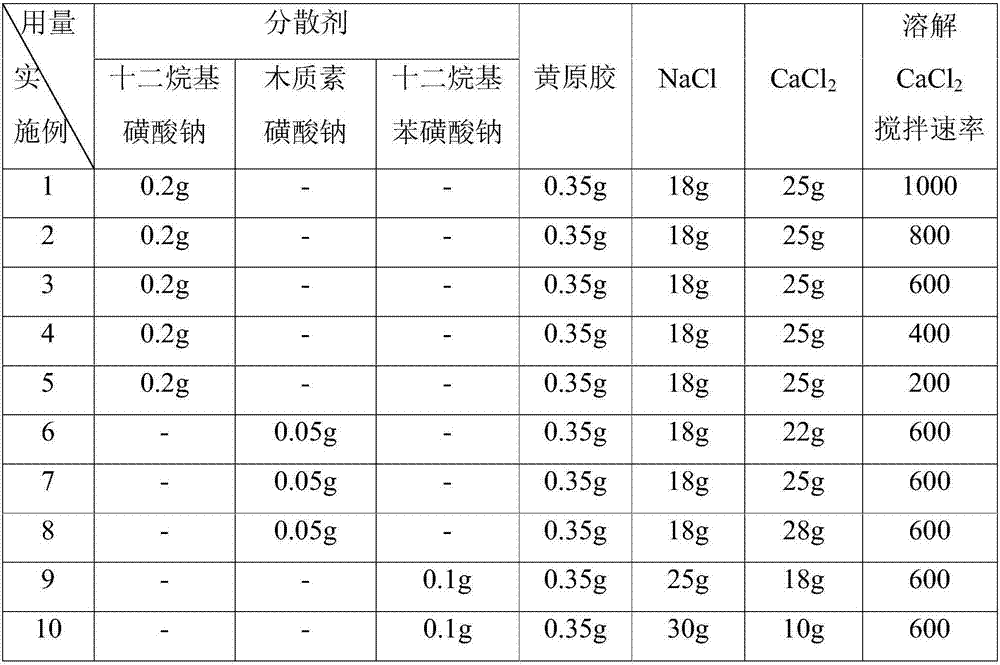

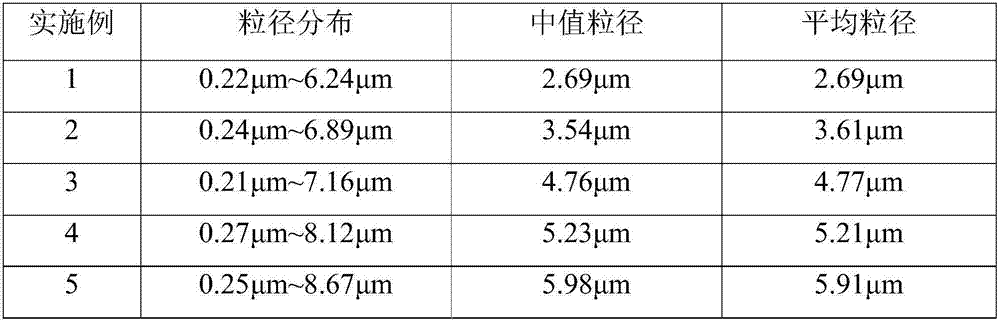

[0042] A high-strength soluble nano-particle temporary plugging agent for fracturing, the selected specific materials and dosage of its dispersant, the dosage of sodium chloride, xanthan gum and calcium chloride, and the specific stirring speed of high-speed stirring are shown in Table 1 below Show.

[0043] Table 1:

[0044]

[0045] The specific preparation method of the temporary plugging agent is as follows: at room temperature, measure 100mL deionized water and add it to the beaker, add the dispersant to the beaker, stir for 30 minutes until completely dissolved, then add sodium chloride and xanthan gum, and stir for 40 minutes , so that the two are completely dissolved in water; then add calcium chloride to the beaker and stir at a high speed for 1 hour to obtain a temporary blocking agent in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com