Method for extracting technetium from molybdenum solution adopting polyamide resin

A technology using polyamide and polyamide resin, which is applied in the field of radionuclide separation, can solve problems such as poor radiation resistance, poor consistency of chromatographic columns, and complex material structure, and achieve stable adsorption and separation performance and good radiation resistance , low price and easy to obtain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

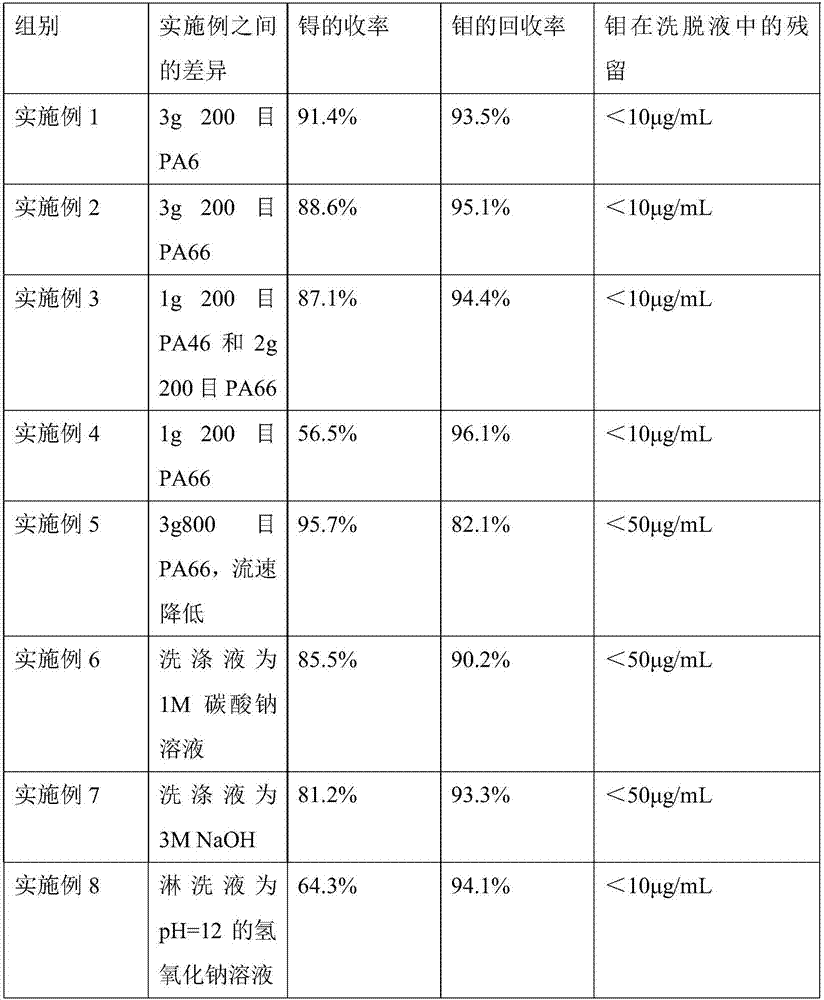

Embodiment 1

[0047] Slowly add 50mL of 6mol / L NaOH aqueous solution to 5g of natural molybdenum oxide powder after thermal neutron activation, so that the molybdenum oxide powder is fully dissolved, and the 99 Mo decays into 99m Tc and 99 Tc, to obtain a mixed solution containing molybdenum and technetium. The hydroxide ion concentration in the obtained solution was 4.6 mol / L. Use 3g of 200 mesh PA6 to make a chromatographic column, pump the mixed solution containing molybdenum-technetium through the chromatographic column at a flow rate of 10mL / min, and recover the molybdenum-containing effluent. At this point, technetium is adsorbed on the chromatography column. Use 5 mol / L NaOH solution to pump through the chromatographic column at a flow rate of 10 mL / min to wash a small amount of molybdenum attached thereon. Finally, at a flow rate of 10 mL / min, pump through 10 mL of sterile water for injection to elute technetium on the column. The obtained eluent is a solution containing techne...

Embodiment 2

[0049] Slowly add 50mL of 6mol / L NaOH aqueous solution to 5g of natural molybdenum oxide powder after thermal neutron activation, so that the molybdenum oxide powder is fully dissolved, and the 99 Mo decays into 99m Tc and 99 Tc, to obtain a mixed solution containing molybdenum and technetium. The hydroxide ion concentration in the obtained solution was 4.6 mol / L. Use 3g of 200 mesh PA66 to make a chromatographic column, pump the mixed solution containing molybdenum-technetium through the chromatographic column at a flow rate of 10mL / min, and recover the molybdenum-containing effluent. At this point, technetium is adsorbed on the chromatography column. Use 20 mL of 5 mol / L NaOH solution to pump through the chromatographic column at a flow rate of 10 mL / min to wash a small amount of molybdenum attached thereto. Finally, at a flow rate of 10 mL / min, pump through 10 mL of sterile water for injection to elute technetium on the column. The obtained eluent is a solution contain...

Embodiment 3

[0051] Slowly add 50mL of 4mol / L NaOH aqueous solution to 5g of natural molybdenum oxide powder after thermal neutron activation, so that the molybdenum oxide powder is fully dissolved, and the 99 Mo decays into 99m Tc and 99 Tc, to obtain a mixed solution containing molybdenum and technetium. The hydroxide ion concentration in the obtained solution was 2.6 mol / L. Mix 1g of 200-mesh PA46 and 2g of 200-mesh PA66 to make a chromatographic column, pump the mixed solution containing molybdenum-technetium through the chromatographic column at a flow rate of 10mL / min, and recover the molybdenum-containing effluent. At this point, technetium is adsorbed on the chromatography column. Use 20 mL of 5 mol / L NaOH solution to pump through the chromatographic column at a flow rate of 10 mL / min to wash a small amount of molybdenum attached thereto. Finally, at a flow rate of 10 mL / min, pump through 10 mL of sterile water for injection to elute technetium on the column. The obtained elue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com