Method for treating refrigerant with freon and equipment of method

A refrigerant and freon technology, which is applied in the field of dealing with freon refrigerants, can solve the problems of resource waste, refrigerant danger, high power consumption, etc., and achieve the effect of avoiding heat loss and easy catalyst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

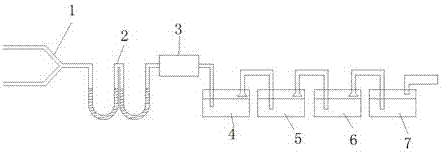

[0022] like figure 1 The method for treating refrigerants with Freon is to dehydrate and dry aluminum sulfate, copper sulfate, and aluminum phosphate to make them into granules. In the reactor 2, a tee pipe 1 is arranged at the inlet end of the U-shaped reactor 2, and the outlet end of the tee pipe 1 is connected with the inlet end of the U-shaped reactor.

[0023] The inlet ends of the three-way pipe 1 are respectively supplied with water vapor and refrigerant with Freon, and the volume flow of the water vapor is twice that of the refrigerant with Freon. The water vapor and the refrigerant with Freon are introduced into the U-shaped reactor 2 at the same time, and the flow rate of the water vapor and the air flow with the refrigerant with Freon are controlled, so that the refrigerant with Freon and the water vapor are in contact with the catalyst for 2min. The air flow out of the U-shaped reactor 2 is cooled to below 10°C by a heat exchanger, then passes through anhydrous co...

Embodiment 2

[0031] like figure 1 The method for treating refrigerants with Freon is to dehydrate and dry aluminum sulfate, copper sulfate, and aluminum phosphate to make them into granules. In the reactor 2, a tee pipe 1 is arranged at the inlet end of the U-shaped reactor 2, and the outlet end of the tee pipe 1 is connected with the inlet end of the U-shaped reactor.

[0032] The inlet ends of the three-way pipe 1 are respectively fed with water vapor and refrigerant with Freon, and the volume flow of the water vapor is three times that of the refrigerant with Freon. The water vapor and the refrigerant with Freon are passed into the U-shaped reactor 2 at the same time, and the flow rate of the water vapor and the air flow with the refrigerant with Freon are controlled, so that the refrigerant with Freon and the water vapor are in contact with the catalyst at 6min. The air flow out of the U-shaped reactor is cooled to below 10°C by a heat exchanger, then passes through anhydrous copper s...

Embodiment 3

[0041] like figure 1 The method for treating refrigerants with Freon is to dehydrate and dry aluminum sulfate, copper sulfate, and aluminum phosphate to make them into granules. In the reactor 2, a tee pipe 1 is arranged at the inlet end of the U-shaped reactor 2, and the outlet end of the tee pipe 1 is connected with the inlet end of the U-shaped reactor.

[0042]The inlet ends of the three-way pipe 1 are respectively fed with water vapor and refrigerant with Freon, and the volume flow of the water vapor is three times that of the refrigerant with Freon. The water vapor and the refrigerant with Freon are passed into the U-shaped reactor 2 at the same time, and the flow rate of the water vapor and the air flow with the refrigerant with Freon are controlled, so that the refrigerant with Freon and the water vapor are in contact with the catalyst at 6min. The air flow out of the U-shaped reactor 2 is cooled to below 10°C by a heat exchanger, then passes through anhydrous copper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com