Micro-fine stand winding enameled copper flat wire and manufacturing equipment and manufacturing technology thereof

A technology for manufacturing equipment and enamelled copper, which is applied in the manufacture of wire harnesses, cable/conductor manufacturing, flat/ribbon cables, etc., can solve problems affecting product paint film adhesion, and achieve excellent paint film adhesion, excellent flexibility, The effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

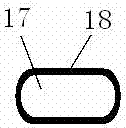

[0035] For the fine vertically wound enamelled copper flat wire of the present embodiment, refer to the attached figure 1 , comprising a metal conductor core 17 and an insulating paint film layer 18 covering the outside of the metal conductor core 17; the insulating paint film layer 18 is a polyurethane resin layer, a polyesterimide resin layer, a polyamideimide resin layer Any one of them; the metal conductor wire core 17 is a copper conductor; the polyurethane resin layer is an insulating varnish layer formed by baking polyurethane varnish, and the polyesterimide resin layer is an insulating varnish formed by baking polyesterimide varnish In the film layer, the polyamide-imide resin layer is an insulating paint film layer formed by baking polyamide-imide paint.

Embodiment 2

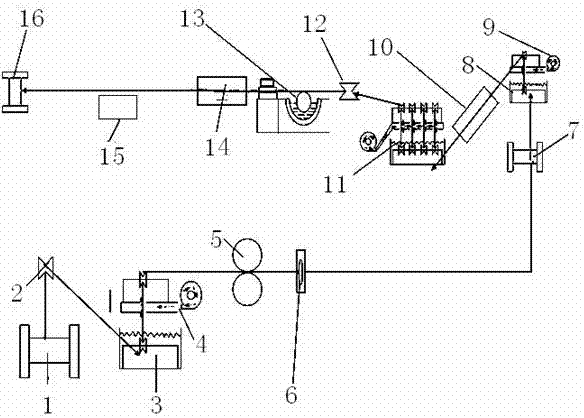

[0037] For the manufacturing equipment of the fine vertically wound enamelled copper flat wire of the present embodiment, refer to the attached figure 2, including a water tank I3 for cleaning the bare copper round wire 1, and a fan I4 for drying the bare copper round wire 1 is installed in sequence at the outlet of the water tank I3, and is used for rolling the bare copper round wire 1 into a bare copper flat wire Roller calender 5, the output end of roller calender 5 is connected with flat wire drawing die 6 for trimming bare copper flat wire, and the output end of flat wire drawing die 6 is connected with bare copper flat wire for winding bare copper flat wire The wire reel 7 and the outlet end of the bare copper flat wire reel 7 are provided with a water tank Ⅱ8, and the outlet of the water tank Ⅱ8 is installed with a fan II 9 and an annealing furnace 10 for softening treatment in sequence, and the outlet of the annealing furnace 10 is provided with cooling and cleaning D...

Embodiment 3

[0039] The manufacturing process of the fine vertically wound enamelled flat copper wire of the present embodiment comprises the following steps:

[0040] 1. The bare copper round wire is put into a special roller calender, and is rolled into a flat wire once or twice according to the wide side and narrow side size of the nominal specification, and then it is trimmed by a flat wire drawing die The standard bare copper flat wire is collected in the bare copper flat wire reel;

[0041] 2. After the bare copper flat wire reel is put into the annealing furnace for softening treatment, the temperature during the annealing and softening treatment is controlled at 500°C. After cleaning with pure water, drying and cooling, the temperature of pure water is 70±5℃, and the air pressure of drying is ≥22Kpa. Then go through the wire wheel and enter the paint area to apply insulating paint multiple times, coat 12-16 layers, and bake in turn to form an enamelled copper flat wire that meets ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com